BoReTech: Wastewater Treatment System Enabling Green Production for Plastic Recycling Facilities

Through the recycling of waste plastic, materials are reintroduced into the production cycle, achieving a “resource-product-waste-recycled resource” loop that prolongs plastic lifespan and effectively reduces the need for landfill and incineration. By recycling plastics, greenhouse gas emissions are decreased, contributing to the mitigation of climate change. As the plastic recycling industry advances, it paves the way for new technologies, plastic, and industries, promoting green innovation. However, with increased plastic recycling comes the critical task of addressing the wastewater treatment during the plastic recycling process.

With years of expertise in plastic washing processes, BORETECH offers customers high-quality wastewater treatment solutions that are energy-efficient, low-emission, and highly effective. Our solutions significantly reduce system operational energy consumption, optimize production efficiency, and improve resource utilization. We help businesses lower operational costs while enhancing sustainability, steering them towards a greener, more efficient production model that conserves our planet’s valuable resources and builds a brighter future.

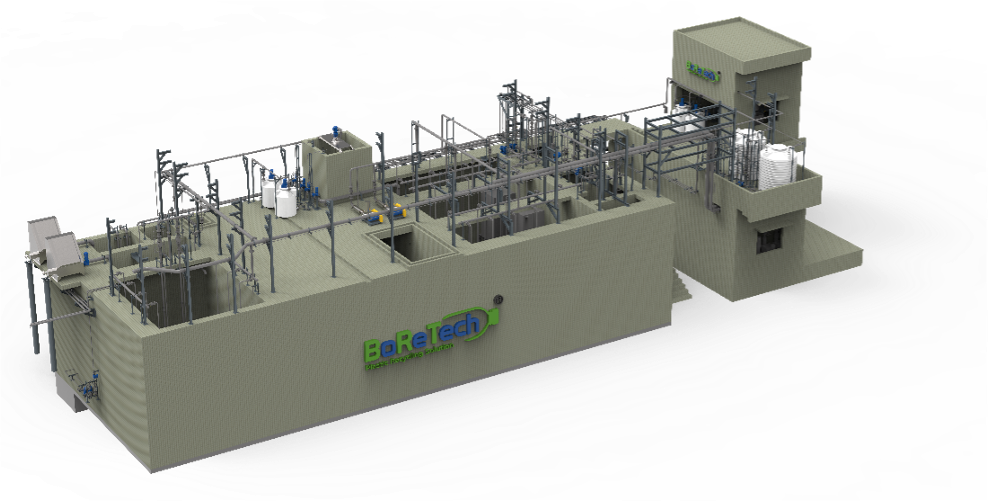

The BORETECH E4-Aps Wastewater Treatment System introduces optimized wastewater treatment processes for plastic recycling and regeneration. Our system integrates anaerobic-biological and physicochemical-biological processes, supplying customers to choose suitable process routes based on the specific wastewater composition from each plastic recycling production line.

Anaerobic + Biological Process

1. Pretreatment Unit: Adjusts pH, homogenizes, and finely filters to remove impurities larger than 0.5 mm, ensuring stable operation of downstream wastewater treatment equipment.

2. Anaerobic Process: Under anaerobic conditions, macromolecular organic matter is hydrolyzed and acidified into small-molecule organic acids, carbon dioxide, and hydrogen, significantly reducing the chemical oxygen demand (COD) of the wastewater.

3. Methane Generation: Methane produced in the anaerobic process can be reused as electricity and heat, supplying energy to the production and wastewater treatment processes.

Key Benefits of Anaerobic + Biological Process

- High capacity, suitable for wastewater rich in polysaccharides, proteins, and other organics.

- Reduced sludge output, lowering sludge treatment costs and cutting sludge production by ~30%.

- Energy recovery, reducing operational energy consumption and lowering carbon emissions by 20-25%.

- Cost advantage in long-term operations, with a ~15% reduction in operational costs.

- Requires precise control of operating conditions.

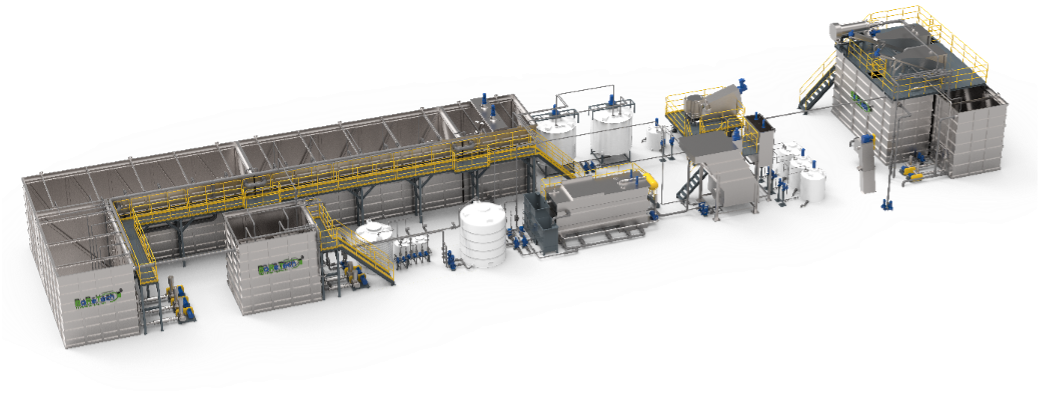

Physicochemical + Biological Process

1. Coagulation and Flotation: By adding polyaluminum chloride (PAC) and polyacrylamide (PAM) sequentially, organic colloids in the wastewater destabilize and coagulate. Sedimentation removes denser particles, while flotation effectively removes lighter oil particles (<100μm) by floating them on microbubbles for easy removal. This process effectively eliminates suspended solids and oil from the wastewater.

Key Benefits of Physicochemical + Biological Process

- Highly effective for lower-volume wastewater with relatively low organic content.

- Strong resistance to fluctuations in water quality, handling up to 50% suspended solids variation.

- Excellent performance in removing suspended solids and grease content.

- Compact equipment with low space requirements.

- Economically feasible, with lower initial investment and easy maintenance.

- Short system start-up time, becoming operational within two weeks.

The addition of UF+RO processes and evaporation can achieve near-zero wastewater discharge, supporting green production in plastic recycling and washing plants.

This sustainable approach aligns with our commitment to green innovation and positions BORETECH as a key player in promoting cleaner, resource-efficient production systems for a better future.

For more information about plastic recycling system and wastewater treatment solution, contact us [email protected]

Extruders and Extrusion Lines

- Air Bubble Film Extrusion Line

- Air Bubble Film Extrusion Line

- Air Bubble Sheet Co-extrusion Line

- Bag Making Machines

- Blow Film Making Machine

- Blown Film Extruders

- Blown Film Making Machine

- Cast Film Machine

- Coating Machine

- EPS/EPE Foam Sheet Extrusion Lines

- Extruder

- Extrusion Laminating Machines

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Monofilament Extruding Machinery

- Monofilament Extrusion Line

- PET Strapping Band Extrusion Lines

- Plastic Bag Making Machines

- Plastic Film Co-Extrusion

- Plastic Pipe Making Machines

- Plastic Tube Making Machine

- PVC Hose Making Machine

- Straw Making Machines

- Twin Screw Extruder

- Twin Screw Extruders

- Woven Bag Making Machine

Plastic Recycling Machinery

- Bottle Washing Line

- Crusher

- Granulators

- Pelletizer

- Pelletizers

- Pelletizing Machines

- PET Bottle Recycling Line

- PET Hot Washing Line

- Plastic Pelletizing Machines

- Plastic Recycling Equipment for Preprocessing

- Plastic Recycling Machines

- Plastic Waste Recycling Machine

- Recycling Lines

- Recycling Machine

- Shredders

- Squeezers

- Washing Lines

- Waste Recycling Equipment