HCI Provides Latest Technology of Medical Sterilization Pouch / Reel Making Machine

Global demand for medical packaging continues to grow, quality standard expected of the sterile pouches/ reels also set to increase and become more stringent. HCI is aware of this trend and has since collaborated with MNCs to make critical changes to its medical pouch making machine to meet this new standard. More operator oriented features, stable and reliable machine with more precise temperature control are the key. A new “FSC-V” is recently launched, capable of making different type of sterile pouches including header bags, heat-seal and self-sealing type sterile pouches, flat and gusset sterile reels.

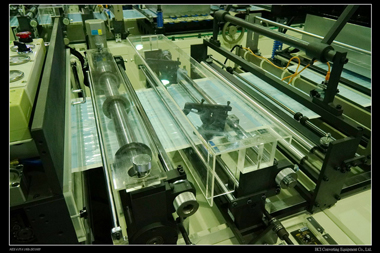

HCI’s ‘ FSC-V’ medical sterilization pouch making machine’s sealing mechanism utilizes external drive system which is simple and easy to maintain and up keep. Its main drive is servo motor driven and heat sealing time can be varied according to pouch material type. Sealing temperature does not require adjustment while the machine mechanical speed changed. Material feeding is also servo motor controlled ensuring every pouch size is consistently the same.

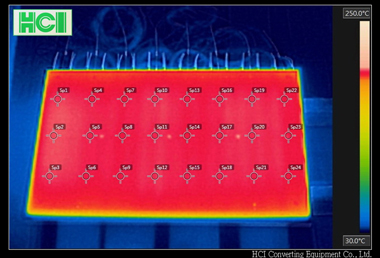

Heal seal’s sealing pressure and temperatures are 2 critical parameters for ensuring the quality integrity of sterile pouches. FSC-V sealing embossing device utilizes compact cylinder delivering well balance all round pressure to the top and bottom sealing molds, keeping material deformation within 0.01mm during sealing process, especially suitable for paper and film sealing, delivering stronger seal and neat bond.

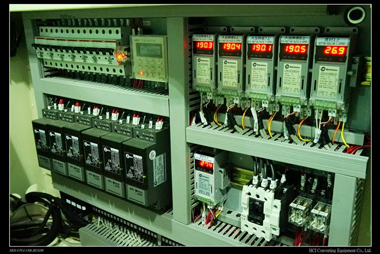

On sealing temperature, FSC-V could be customized to utilize 4 – 8 independent temperature controller according to customer’s requirement. Every set of temperature controller comprises of heaters, thermocouples and PID thermal controller. Each temperature controller will use HCI's unique heat distribution technology to independently control each area, and the temperature on each sealing mold will be kept within +/- 2.5°C to ensure zero sealing defects.

Other new operator friendly features on FSC-V include improved mold track for easy changing of sealing mold to meet different orders. New inline shear knife changing and slitting width changing features are added, without the need to remove knife shaft. HMI touch screen offers easier entering and monitoring of process parameters. The new FSC-V with its new and improved machine design has improved workflow and enhanced safety features, delivering better seal quality, better product and reduces wastage. HCI will continue to bring in new advance technology and providing the most practical converting solution to clients.

Please click here to check: Medical Sterilization Pouch/Reel Making Machine - FSC-V

|

Official Website https://www.hci.cc/ HCI in PRM https://www.prm-taiwan.com/com/hci.html |

E-News Categories

Extruders and Extrusion Lines

- Air Bubble Film Extrusion Line

- Air Bubble Film Extrusion Line

- Air Bubble Sheet Co-extrusion Line

- Bag Making Machines

- Blow Film Making Machine

- Blown Film Extruders

- Blown Film Making Machine

- Cast Film Machine

- Coating Machine

- EPS/EPE Foam Sheet Extrusion Lines

- Extruder

- Extrusion Laminating Machines

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Monofilament Extruding Machinery

- Monofilament Extrusion Line

- PET Strapping Band Extrusion Lines

- Plastic Bag Making Machines

- Plastic Film Co-Extrusion

- Plastic Pipe Making Machines

- Plastic Tube Making Machine

- PVC Hose Making Machine

- Straw Making Machines

- Twin Screw Extruder

- Twin Screw Extruders

- Woven Bag Making Machine

Plastic Recycling Machinery

- Bottle Washing Line

- Crusher

- Granulators

- Pelletizer

- Pelletizers

- Pelletizing Machines

- PET Bottle Recycling Line

- PET Hot Washing Line

- Plastic Pelletizing Machines

- Plastic Recycling Equipment for Preprocessing

- Plastic Recycling Machines

- Plastic Waste Recycling Machine

- Recycling Lines

- Recycling Machine

- Shredders

- Squeezers

- Washing Lines

- Waste Recycling Equipment