Whatever Type Of Blown Film Extruder You Need, Kung Hsing Can Make It For You!

Kung-Hsing Plastic Machinery Co., Ltd. was established in 1972, specialized in making plastic extruders, as well as special customized design for all extrusion system and whole plant projects. The Machine sold to worldwide more than 120 Countries and has achieved ISO 9002 and CE standard. With good reputation, strong R&D dept., and technical working term, KS provides the best quality, high performance, energy saving machinery and satisfactory after sale service.

APPLICATIONS OF FILM:

Barrier film, lamination film, VCI film, Stretch hood, Food packaging film, Industrial packaging film, FFS, Heat shrinkable film, Stretch film, Cling film, and Agriculture film, and etc.

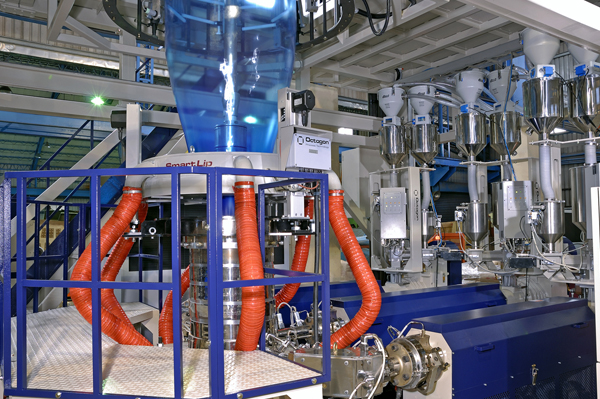

BLOWN FILM SYSTEMS:

We offer complete blown film extrusion lines from 3 layers up to 7 layers to process HDPE, NDPE, LDPE, LLDPE, mPE, EVA, PP, PA, EVOH, blends and recycled material.

RANGE OF EXTRUDER:

Extruders with diameters from 45 mm to 150 mm

RANGE OF DIE HEADS:

● 3 layer spiral mandrel dies with diameters from 150 mm to 1350 mm

● 3, 5, 7 layer spiral mandrel dies or stackable dies with diameters from 200 mm to 650 mm

COOLING SYSTEMS:

High efficiency internal and external cooling system in various styles:

● Standard cooling rings with dual lips,

● Internal bubble cooling (I.B.C.) system,

● Height adjustable cooling ring system

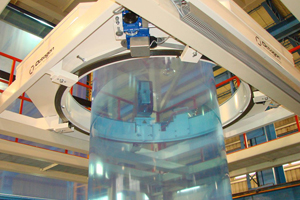

TAKE UP UNIT:

● Oscillating take off (horizontal type) with air turning bars from 800 mm to 2400 mm

● Stationary take off with widths from 800 mm to 6000 mm

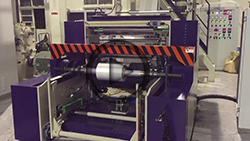

WINDERS:

● Stationary contact winder in single or dual winder configurations

in widths from 800 to 3500 mm

● Stationary contact / center / gap winder in single or dual winder configurations

in with widths from 800 mm to 2600 mm

OPTIONS AVAILABLE:

We cooperate with worldwide famous suppliers for following options

(Plast control, Doteco, Octagon, TSM, Syncro, Kundig, and etc.)

● Continuous loss-in-weight gravimetric dosing system and gravimetric gain-in-weight batch blender with extrusion control system: precise material dosing, throughput control, lineal weight control, and layer gauge control (control layer thickness ratio for co-extrusion line)

● Thickness measurement system with automatic profile control air ring to perform film thickness variation between ±2~3%

● Width measurement system with automatic width control system

For more videos about Kung-Hsing, please click the picture as below:

|

More Information on PRM: http://www.prm-taiwan.com/com/kunghsing.html Official Website: http://www.kunghsing.com.tw |

Extruders and Extrusion Lines

- Air Bubble Film Extrusion Line

- Air Bubble Film Extrusion Line

- Air Bubble Sheet Co-extrusion Line

- Bag Making Machines

- Blow Film Making Machine

- Blown Film Extruders

- Blown Film Making Machine

- Cast Film Machine

- Coating Machine

- EPS/EPE Foam Sheet Extrusion Lines

- Extruder

- Extrusion Laminating Machines

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Monofilament Extruding Machinery

- Monofilament Extrusion Line

- PET Strapping Band Extrusion Lines

- Plastic Bag Making Machines

- Plastic Film Co-Extrusion

- Plastic Pipe Making Machines

- Plastic Tube Making Machine

- PVC Hose Making Machine

- Straw Making Machines

- Twin Screw Extruder

- Twin Screw Extruders

- Woven Bag Making Machine

Plastic Recycling Machinery

- Bottle Washing Line

- Crusher

- Granulators

- Pelletizer

- Pelletizers

- Pelletizing Machines

- PET Bottle Recycling Line

- PET Hot Washing Line

- Plastic Pelletizing Machines

- Plastic Recycling Equipment for Preprocessing

- Plastic Recycling Machines

- Plastic Waste Recycling Machine

- Recycling Lines

- Recycling Machine

- Shredders

- Squeezers

- Washing Lines

- Waste Recycling Equipment