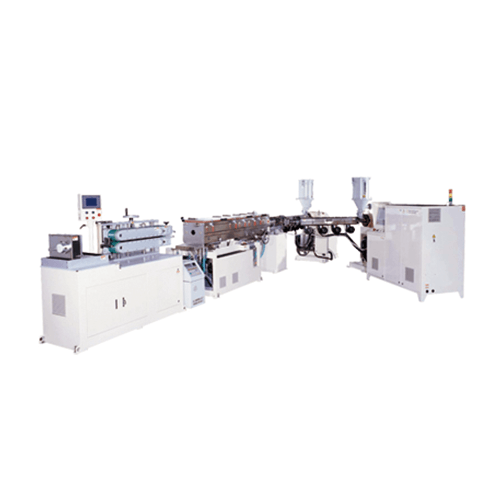

RePET Wood WPC Co-Extruder

Categories : Extrusion Lines For Pipes and Profiles

RePET Wood WPC Co-Extruder Single screw

Co-Extruder, Co Extrusion Machine

Categories : Extrusion Lines For Pipes and Profiles

Part for indoor and outdoor application: Door Frames, Furniture Components, Spacing Panels, etc.

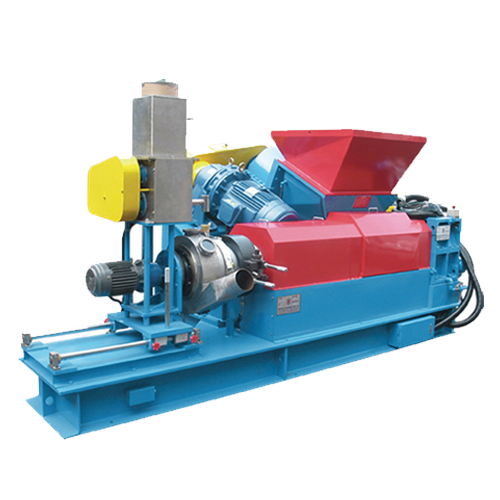

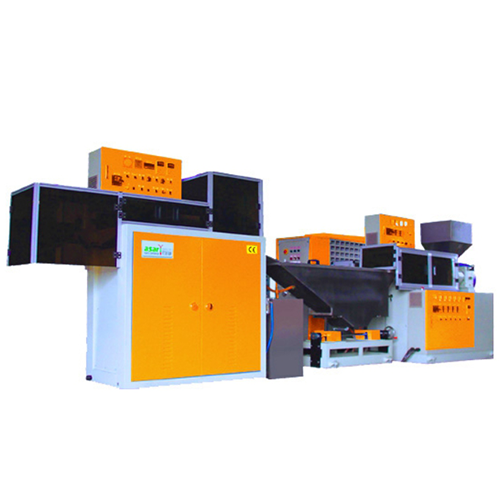

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

Extrusion & Pelletizing for Rubber、Plastic & Chemical Industries This new model Feeder-Ruder Pellet Making Extruder usage for extruding and pellet making after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind.

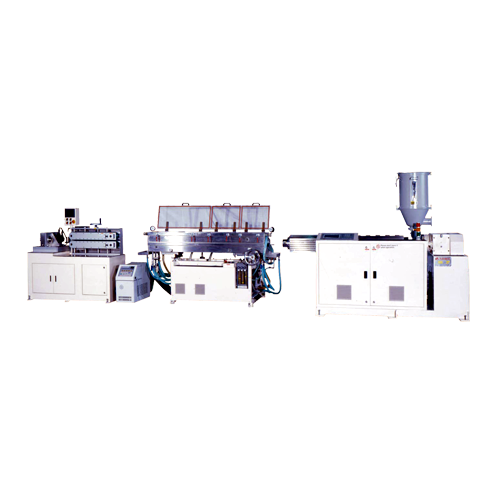

Tandem Extruder Machine (YSJ)

Categories : Extrusion Coating Machines

● Working Material: BOPP film, CPP film, PET film, Cellophane, Aluminum foil, Paper, Non-woven fabric, PE film, Nylon film ● Resin: PP / LDPE / LLDPE / EVA / EAA / SURLYN

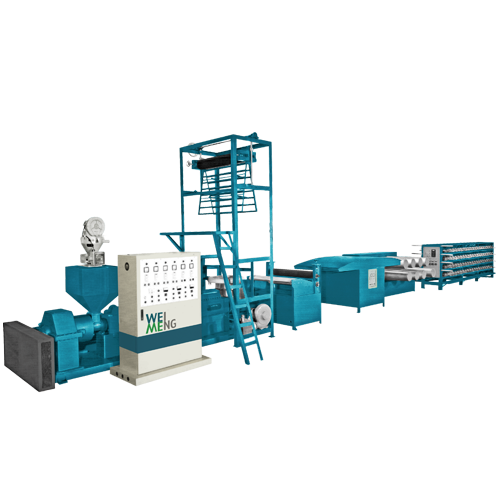

Flat Yarn Making Machine

Categories : Extrusion Lines For Filaments and Yarn

Wei Meng Industrial Co., Ltd. is specialized in manufacturing flat yarn making machine for many years. Based on continuously research and development foundation, the latest models have been launched irregularly. Until now, in our flat yarn making machine, we offer many models such as JO-85, JO-100, etc. Besides, we provide a cheaper price and superior service to all customers. Please click the online category, and you will get more detailed product feature and specification of flat yarn making machine.

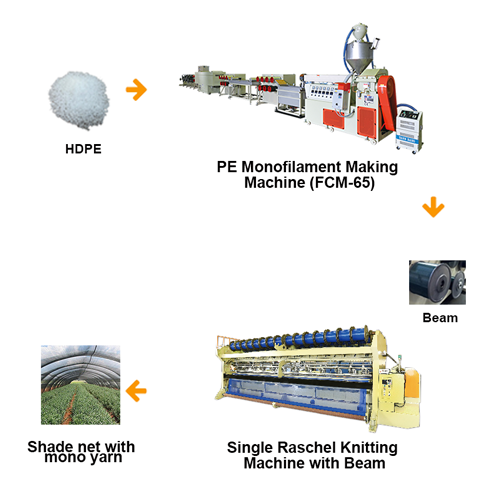

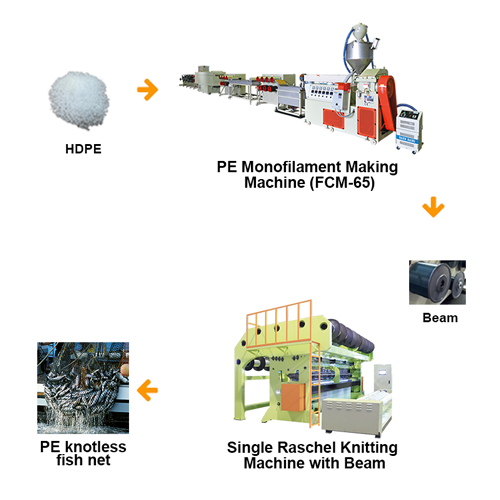

PE Knotless Fish Net

Categories : Industrial Knitting Machines

Raschel Knitting Net, PE Knotless Fish Net

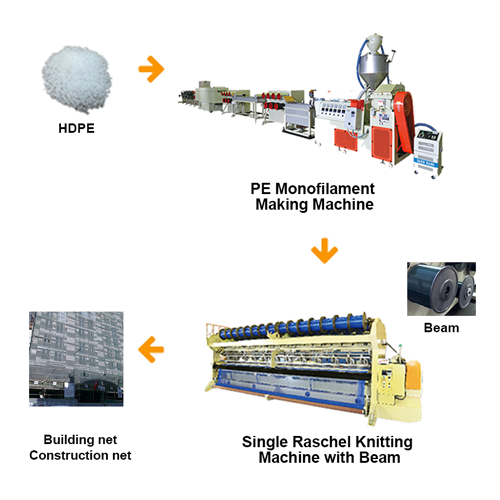

Building / Construction Net

Categories : Industrial Knitting Machines

This extrusion line is designed for making monofilament and suites for PE raw material. It can offer the round yarn (monofilament) to model SR-R & DR-R knitting machine. Model SR-R series is Single needle bed Raschel knitting machine which design for making the Round yarn (mono yarn) in all different kind of raw material, for example Nylon, PE, PP etc.

Polyester Zipper Monofilment Making Machine

Categories : Extrusion Lines For Filaments and Yarn

K.S. became a worldwide company; have achieved ISO 9002 certificate's requirements. K.S. machinery conforms to CE standard. Moreover, every machine must pass K.S. strict and careful quality control system, and pass test running before shipping out to the customer.

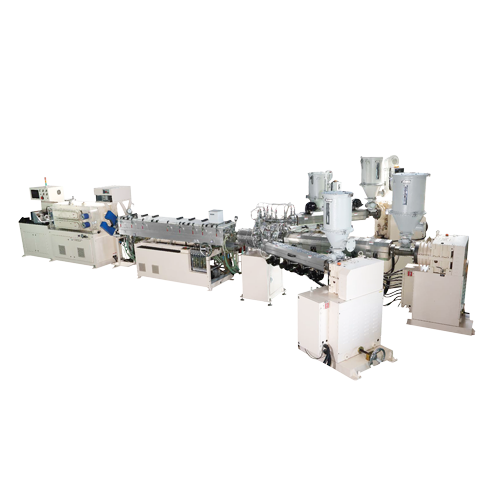

PE Monofilament Making Machine FCM-65

Categories : Industrial Knitting Machines

FCM-65 is the monofilament making machine with beam type winder which suites for HDPE raw material. It is suitable for our model SR-R, SR-RF & DR-R knitting machine. The winder is direct beam type so it doesn’t need to use the warping machine. Customer can save a working process of warping and also save the plant space.

Monofilament Making Machine

Categories : Extrusion Lines For Filaments and Yarn

According to the processing purpose of monofilament, there are two types, one is two stages type (Equipped with stretching and annealing devices, the other is one stage type (Equipped with annealing device only).

High-Speed Zipper Profile Extruder INLL

Categories : Co-Extrusion Blown Film Machines

Zipper profile extrusion - Profile extruded by extruder directly into cooling water tank for formation. Profiles are closed and collected by carton or optional winder.

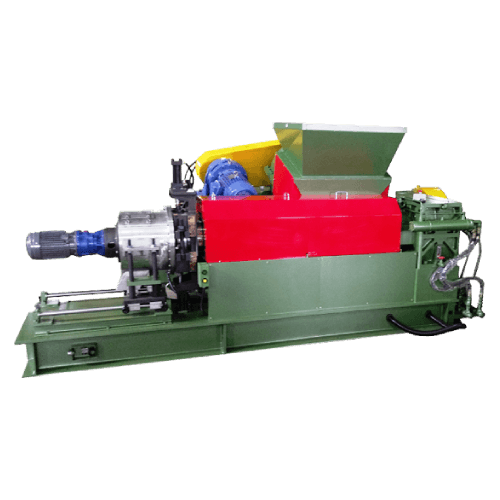

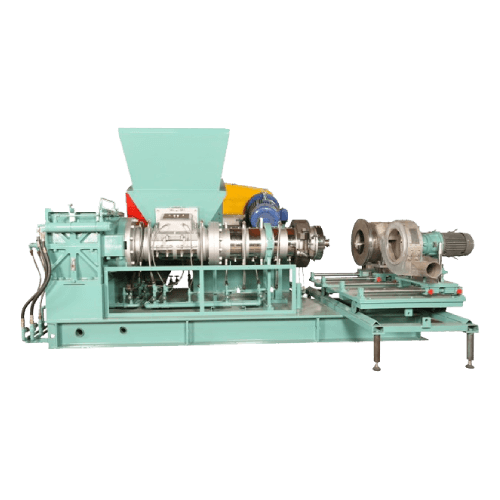

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

This new model Feeder-Ruder Pellet Making Extruder usage for extruding and pellet making after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind.

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

This new model Feeder-Ruder Pellet Extruder usage for extruding and pellet producing after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind..

High Speed Multi-layer PE Tube Extruder and Cutting Machine EDC-16-05

Categories : Cutting Machines

-High speed & high output -High precision thickness control on each layer of tube -Simplified control -Quick tooling change by one operator -Closed loop cooling water circulation system -Caterpillar haul-off -Automatic outer diameter control unit (optional) -Low power consumption and high production efficiency

Two-Layer PE Tube Extruder & Cutting Machine EDC-08-02

Categories : Cutting Machines

-Two-layer extrusion tube can reduce material cost. (using: Pearl + PE/PE + Pigment) -The temperature controllers of different materials can be controlled individually. In this way, we can find out the best running condition on the materials both in running fluency and dissolubility. -The surface of co-extrusion tubes made by two-layer machine is more glossy than the surface of mono-layer tubes. -Using the same material on two-layer same material on two-layer co-extrusion can increase the water-resistance and anti-penetration of the materials for about 20~30%. (using: PE + Pigment. inner: recycled material.)

Triple Extruder Machine (YSJ)

Categories : Extrusion Lamination Machines

● Working Material: BOPP film, CPP film, PET film, Cellophane, Aluminum foil, Paper, Non-woven fabric, PE film, Nylon film ● Resin: PP / LDPE / LLDPE / EVA / EAA / SURLYN

Mono-Layer PE Tube Extruder & Cutting Machine EDC-08-01

Categories : Cutting Machines

Extrusion is the first process of making PE tubes. This process ensures glossy surface, even thickness and well-balanced composition of plastic materials. For years of research and development, our remarkable achievements on LLDPE & LDPE melting, screw design, device of die head, material adoption, and surface treatment, together with size control by figuration and length restraint by encoder have produced valuable and high-quality tubes.

Multi-Layer High Speed Co-Extrusion Zipper Profile Extruder ( AB45AZ)

Categories : Co-Extrusion Blown Film Machines

MULTI-LAYER HIGH SPEED CO-EXTRUSION ZIPPER PROFILE EXTRUDER

High Speed Zipper Profile Extruder( AB-40Z)

Categories : Plastic Bag Making Machines

HIGH SPEED ZIPPER PROFILE EXTRUDER

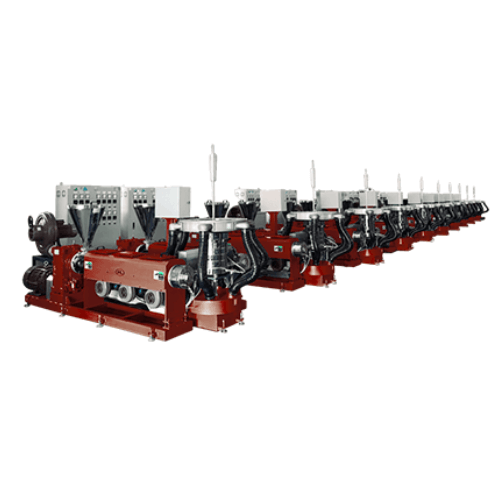

Twin Screw Roller (TSR) Head Extruder

Categories : Rubber Extrusion Lines

MACHINE FUNCTION: The Twin Taper Screws Roller Head Extruder consists of two tapered screws and two rollers,The machine is normally applied for processing to a dispersion kneader or an intensive mixer. The rubber material,mixed by a dispersion kneader or an intensive mixer,is then fed to the rollers through the two tapered screws.It calenders the material to a desired sheet form at a constant speed. The machine is designed and engineered for high speed sheet forming operations

ABA Blown Film Extruders

Categories : Blown Film Extruder Parts

The main characteristics of these kind of Extruder is available to use two or more materials to manufacture film. Eterlong supply customized machine specifications for different output, material, film width, film thickness. Further, it reduces the waste of material cost since it allows to add CaCo3, recycled material and color masterbatch in the middle layer for different using.

Co-Extrusion Blown Film Extruders

Categories : Extrusion Dies / Dies Heads

HSIN LONG’s Co-Extrusion Extruder is customized which depends on characteristics of raw materials and final applications. Since there are kinds of materials will be extruded at the same time, the flow channel with special design helps polymers to flow smoothly without any residue. As the need of marketing trends and the transformation in blown film industry, it is available to use recycled and colored material for more functional use.

Pellet Extruding Machines Screws / Barrels

Categories : Screws and Barrels

As leading company of Screws and barrels in Taiwan, Nan Yun is able to provide the highest quality screw and barrel for Extruder Machine. We are continually researching new screw and barrel materials that would best fit the needs for pellet extruder or plastic pelletizing machine, which results in better mixing, and critical melt quality. Nan Yun's engineers work with our customers to provide the best possible extruder screw design for extruder machine such as PVC pelletizing machine, PE pelletizing equipment, Plastic pellet extruder.