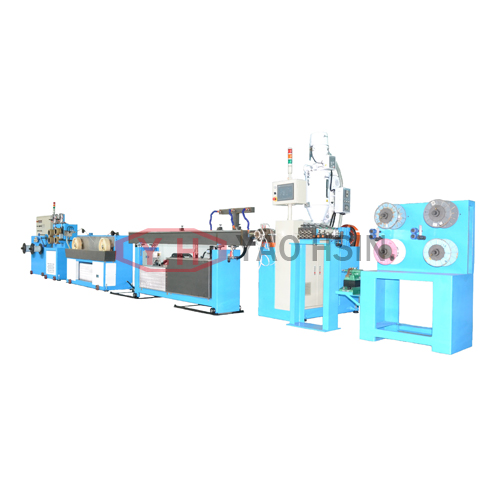

Continuous Mixer with Extrusion Pelletizing Liner

Categories : Plastic Pelletizer Machines

Mixing is needed to get the right consistency within masterbatch making machines. This Extrusion Pelletizing line has been constructed to focus on mixing different types of raw materials, so that the consumer can produce a multitude of different pellets for various different applications. We can also provide automated production line for you, and to adjust and customize equipment according to your needs.

Vacuum packaging machine - HIPPO

Categories : Vacuum Packaging Machines

Vacuum water content: the water collection cup inside the body

5 Fold Garbage Bag Making Machine

Categories : Plastic Bag Making Machines

Flat bag style, 5 fold garbage bag making machine.

JS Series-Double Station

Categories : Automatic Blow Molding Machines

●Hydraulic type Plastic Blow Molding Machine. ●Automatic production design. ●Mold Open/Close/Move by cylinder. ●Gearbox drive extruder system. ●PLC control with Touch Screen for function, time, pressure...etc. ●Diversified parison knifes and multihead choices depend on the requirement. ●Proportional pressure hydraulic system. ●Especially for 2 liter bottle and 5 liter bottle.

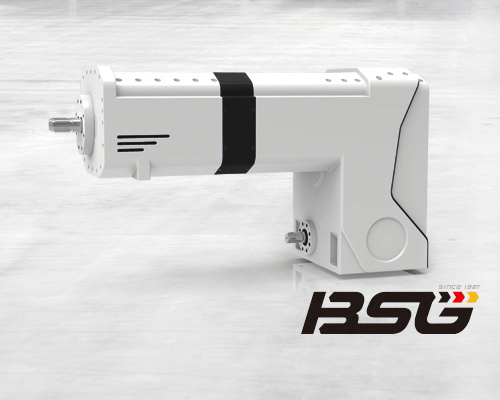

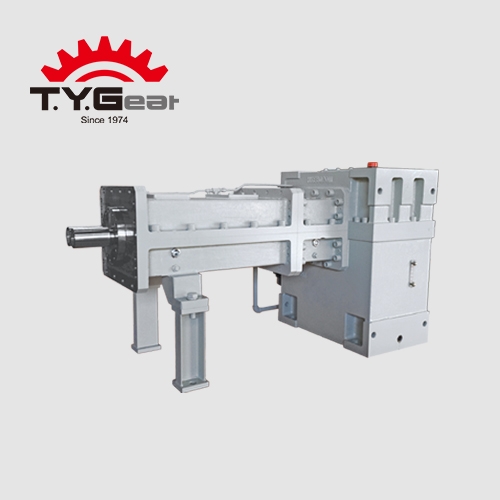

Counter Rotating Gearbox

Categories : Gears

SINGLE-SHAFT TYPE SEMI-AUTOMATIC ALUMINUM FOIL & CLING FILM REWINDER (SRB-A-1S 20-50)

Categories : Slitters and Rewinders

SRB-A-1S, one shaft type semi-automatic rewinding machine. It's a strongly stable machine for rewind aluminum foil & cling film. Which is friendly, easy-operate for a novice. SRB-A-1S is compatible for cling film and catering aluminum foil. It can solve the temporary requirement when you need to exchange materials. The mother roll available width is from 200-500 mm. The max rewinding speed is up to 500M/min. The finished product can be 1000M the longest. Machine uses electric speed adjustments. You can control the rewinding time more precisely, arrange manpower more effectively. SRB-A-1S multiple functions rewinding machine brings you better operation and higher efficacy. Welcome to consult machine with us. We will at your service.

Vertical Type Continuous Dryer

Categories : Dryers and Dehumidifiers For Plastic Materials

High efficiency dryer continues feeding wet materials and continues discharging materials improving traditional dryer to dry wet materials by lot saving your time and cost.

Waste Yarn Bobbin Cleaning

Categories : Industrial Knitting Machines

Dedicated design for removing waste yarn on bobbins with high efficiency

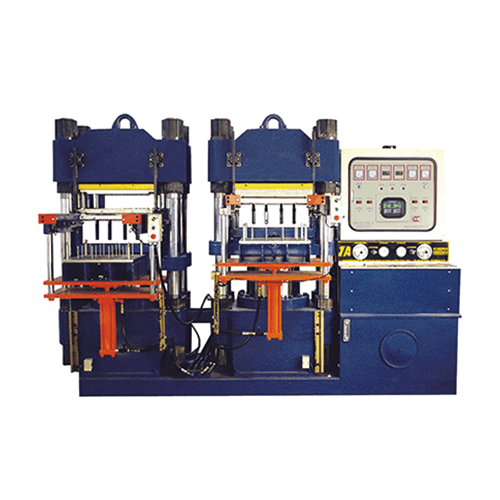

Tire Valve Rubber/Silicon Compression Molding Machine

Categories : Compression Molding Machines

Type 300 tons Horse power 10 Hpx2 Stroke 300 mm Working bench 600x600 mm Designed for tire valves, high yield and efficient. Nature rubber Rubber of metal bonded parts Oil-resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber tyre valve

Multi-Layer Compression Molding Machine

Categories : Compression Molding Machines

Multi-Layer Compression Molding Machine Nature rubber Rubber of metal boned parts Oil resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber

OPTIONAL DEVICES FOR PLASTIC BLOWN FILM

Categories : Assembly Systems

FEATURES Full range of equipment will meet your machine requirement, we also provide machine parts selling individually (Die head and air ring upgrade, screen changer upgrade, winder upgrade etc.).

Liquid Silicone Rubber Injection Molding Machine

Categories : Rain boot Injection Molding Machines

Applicable for the production of vehicle parts, electronic and medical goods, infant care and food products etc. Save time for production process and increase productivity. The best solution to support quality and efficiency. oxygen mask

P-14

Categories : Injection Molds

Thermosetting Compression Molding Machine

Categories : Compression Molding Machines

Thermosetting Compression Molding Machine Nature rubber Rubber of metal boned parts Oil resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber

Inverter Duty Motor: TFEF Series

Categories : Motors

Higher precision motion control and speed adjustment to make the machine in automation, high production capacity purpose.

Twin Screw Extruder Co-Rotating Type

Categories : Gearboxes

(1) Both Co Rotating & Counter Rotating types of TB series Twin Screw Gear Reducer are composed by Input & Output elements. Especially for output side which installed by Thrust Bearing plus with flange which could suffer high pressure to absorb the axial pressure caused by the extruders. (2) Following AGMA criterion to design gear elements which adopts low-carbon alloy steel bar materials(Normally, it is SCM420 or same level). The precision reaches AGMA 10 level after carburization heat treatment then treating gear surface grinding to make sure low noise, low abrasion and high efficiency during operation. (3) #294 Series Thrust bearing with axial self-aligning roller type & muti-row stacked tandem bearing package to have advantage of low friction heavy axial load capacity.

Wire rope coating PVC、PA12 extrusion line

Application: Coating PVC or PA12 on wire rope to protect wire

3-Layer Mold Vacuum Compression Molding Machine

Categories : Compression Molding Machines

TYC-V-22-3RT-2-S-PCD 3-Layer Mold Demolding (3RT)

Automatic Blow Molding machine- O Series

Categories : Horizontal Blow Molding Machines

Single Die Head or Double Die Heads and Single Station Type, Suitable for View Stripe Containers, Equipped with Auto Conveyor, and Leaking Tester for Quality Supervision.

3D CAD simulation figure & ABS + CNC proofing

The biggest problem in rain boot mold creation is discussion. In the past, 2D sketches were used to discuss patterns and then reference samples were used to assist imagination between both sides. However, rain boots are composed by the curvature of the curved surface of the high variation.Only by 2D sketches and sample auxiliary may lead to a gap between imagination and practices, resulting in continuous modification. Rain boot mould:PVC wellies, boots or foam material wellies and boots shoe mold, shoe mould, mould on shoes, mould shoes,mould in shoes Rain boots, boots, work shoes, gumboot,pvc shoe,eva shoe,pvc boot,plastic shoe,injection shoe

MINI TYPE BLOWN FILM MACHINE

Categories : Blown Film Extruders

Space-saving design Adjustable tower height

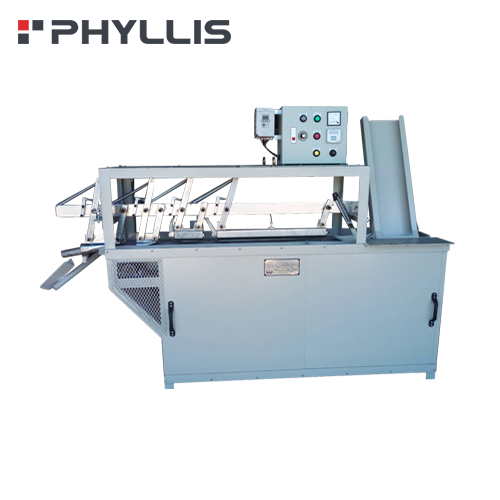

Plastic Spring Molding Machine For The Bind Of Detachable Leaves

PVC plastic spring molding machine for the bind of detachable leaves includes extruded system, mold, molding cutter, which can mold one time, save the secondary processing cost. It is available for stationery, such as table calendar and detachable leaves of notebooks.

Three-layer Co-extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

In/Sn Target

Categories : Bags

Vertical Electric Injection Molding Machine-YE-50V

Categories : Vertical Injection Molding Machines

A number of patented electric injection device Precision electric injection function Precision electric metering function Electric pedestal does not slide function Energy-saving hydraulic servo mold clamping function Accurate low pressure off mode protection function Energy-saving hydraulic servo thimble function Template rust plating processing Template parallelism fine tuning function Template low-top design With 8 T-groove, easy to fix the mold Thick template with high tensile guide posts Configuration template guide column anti-drip bumper sleeve Configure mechanical closing safety bars Configure mechanical shut-off safety electrical protection Open all the safety gates to stop the design Configuration key type safety door safety switch Configuration rail horizontal operation safety gate design Injection device can be flipped to maintain the factory accuracy to reduce the height of the handling method Injection closed loop feedback function Holding pressure switching point accuracy of 0.01mm Packing pressure accuracy of up to 0.1% High-speed rigid filling, to eliminate floating phenomenon Prevent the drawing function A variety of peripheral equipment chain function Equipped with peripheral equipment power outlet With robot centralized terminal block Hopper holder moving function Equipped with resin feed tube holder Equipped with adjustable height white iron trough Equipped with a perspective control water divider Equipped with cooling water quick connector The machine is neat and without any pipe exposure Than the same level of oil-saving 25% to 60% Than the same level oil machine to save cooling water 70% Equipped with 10.4 "color touch screen PID automatic temperature adjustment function Japan's Mitsubishi control system Equipped with wear-resistant material pipe

METAL INJECTION

Categories : Injection Molds

Metal injection molding (MIM) is a metalworking process by which finely-powdered metal is mixed with a measured amount of binder material to comprise a ‘feedstock’ capable of being handled by plastic processing equipment. This is cost-effective for small, intricate, high-volume products which would otherwise be quite expensive to produce by alternate or classic methods. Mold Interconnect Device (MID) integrates a circuit into a plastic part reducing weight and dimensions. We use an innovative assembly process: from injected mold to laser etching then plating with copper or gold. APPLICATIONS Mobile phone’s aerial circuit Medical audiophones Automotive steering wheel Position sensor

PET Stretch Blow Molding Machine -TEM16S2

Categories : Automatic Blow Molding Machines

Blower power consumption for 1000 bottles: 2Wh Air Compressor power consumption for 1000 bottles: 6 kWh compact space Screw driven controlled by servo motor providing fast and smooth motion Single lamp bilateral centralized heating, easy controlled within 3°C and energy heating Low-pressure air compressor will NOT be required due to high-pressure recovery system. High efficient air recovery system up to 45%