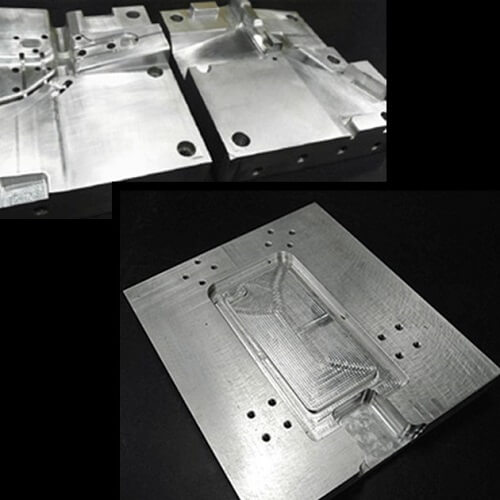

SOFT TOOLING

Categories : Hot Runner Systems

For small production runs or for prototyping, soft tooling is a fast and low cost way to build multiple copies of your product. To provide quick mold soft tooling services our engineers were sent to Japan to learn from soft tooling experts. MATERIALS: Cavity & Core Insert Made from Aluminum or Steel, Mold base free ADVANTAGES: Low Cost & Short Lead Time (5-10 days) Useful for R/D testing and trail runs, reduces final tooling risks Can product approximately 500 Shots DISADVANTAGES: Soft tooling will cycle slower due to poor thermal conductivity of mold material. Material life of soft tooling is limited and will depend upon part complexity. Our mold fabrication shop is equipment with high-end Charmilles EDM and OKK CNC machines. Please visit our Mold Fabrication page for more details.

WT - 60, 90

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 14~26 KW

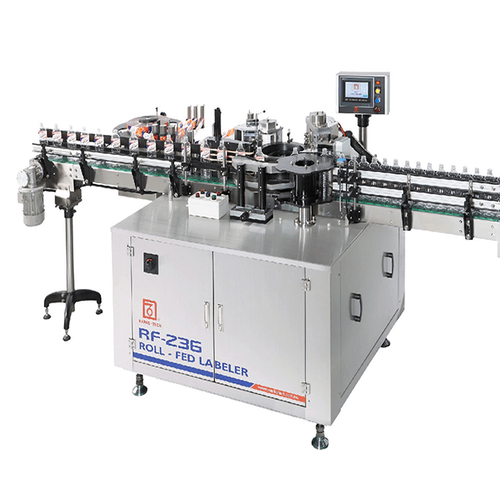

RF-236

Categories : Labeling Machines

RF-236:Round bottle hot melt glue OPP Labele Available for 250cc~1500cc (bottle diameter 50mm~90mm) filled r un-filled round bottle shape labeling application as mineral water bottle, drink bottle, glass bottle, PET bottle, stable speed reaches to 200~300BPM.

POLYCARBONATE CORRUGATED SHEET - L1

Polycarbonate Sheet (PC Sheet) is a high polymer with excellent impact resistance, transparency and light transmission. The PC sheets are widely used in factories, buildings(corridors and windows, etc.)

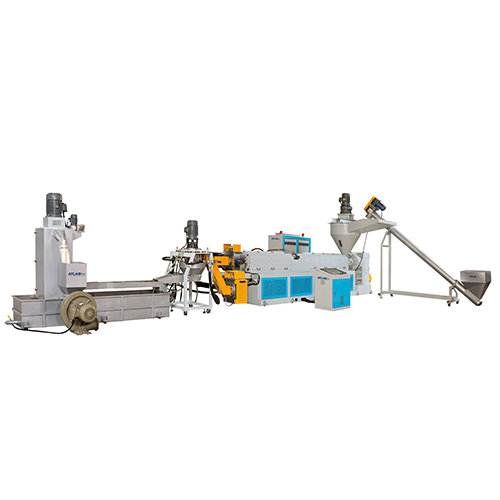

HOPPER FEEDING & DIE FACE CUTTING PLASTIC RECYCLING & PELLETIZING MACHINE

Categories : Plastic Pelletizer Machines

Suitable for shredded fragments from rigid plastics and injection materials

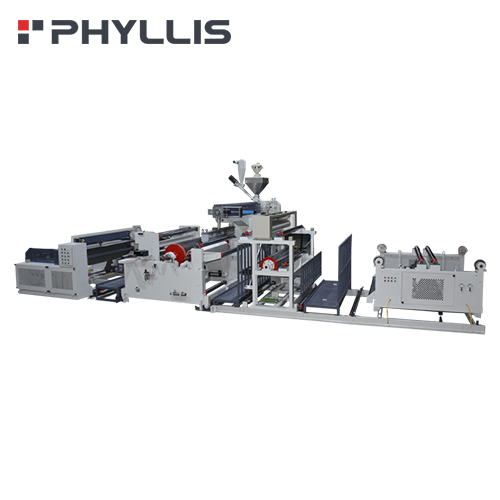

Sheet Extruding Machines - HC-100PLA-1000

Categories : Film and Sheet Extrusion Lines

Although the material of PLA is similar to plastic, it can be decomposed thoroughly in compost. Due to its high transparency and water-resistance.....

Series Mould GF/ISB

Categories : Blow Molding Molds

The machine equips the unique device of Vertical Rotary Disc to transfer the preform from one station to another in an upright position. (Patent)

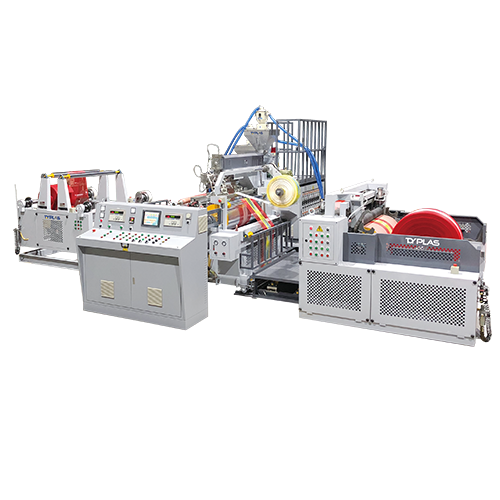

AB & ABA CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Equipped with 2 extruders, A/B or A/B/A type blown film machine is able to produce two-layer film. Co-extrusion able to choose from AB to ABA, ideally for 2 layer film with different colour or apply CaCO3 in middle layer for cost saving, etc. Perfectly suitable to agriculture film, shipping bags, shrink film, consumer packaging and many others.

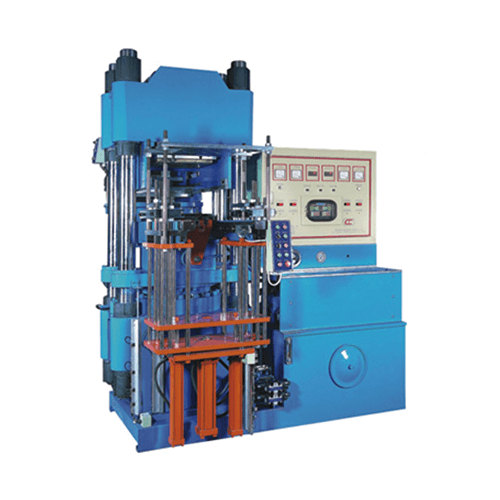

3RT Mold-Open Rubber/Silicon Continuous Transfer Injection Molding Machine-TCC-S3

Categories : Compression Molding Machines

●Nature rubber ●Rubber of metal boned parts ●Oil resistance rubber ●NBR+PVC concoction ●Synthetic rubber ●Medical/Pharmaceutical usage rubber ●Heat resistance rubber

ECO – The Economical Press

Categories : Flexographic Printing Machines

The ECO is the ideal press for those printers and converters new to flexo printing or looking for a low-cost central impression printing machine and a quick return on investment. You can own the industrial standard at much lower capital investment. If you are looking for an introductory CI solution, this is the press for you to customize.

MICRO MOLDING

Categories : Injection Molds

Micro molding is a very specialized art form, which is a kind of tooling design , manufactures small and precision plastic components with polymer-based functional devices, by increasingly demanded in the fields of life science, electronics, medical, photonics, automotive, and aerospace. The tiny-scale molding form of injection molding that entails building a cavity to match the shape of the part you want to make, sort of like the plastic molding that makes Lego bricks. THERE ARE THREE DIFFERENT THINGS TO KEEP IN MIND WITH MICRO MOLDING : Micro means the size of the part. It is the most common definition when dealing with micro molding. Micro features relates to tiny parts on a larger part. As a whole, the part can be big, but its components can be smaller, or micro features. Micro tolerance is how the parts are measured and how close to the needed measurement the part has to be to be considered a good or usable part. When a part is molded, it has to measure within the needed measurement (the tolerance), which could be as small as a thousandth of an inch. Small parts that are simple to make have tolerances that are not as tight and would be considered regular molding. SOME ADVANTAGES OF DESIGN GUIDE IN YOMURA AS : Dimension Aspect ratios around 6:1 (material dependent) Wall thickness : 0.3 mm ( 0.012”) min. for plastic Hole dimension : 0.2mm ( 0.008”) – 0.5mm ( 0.02”) min. Pitch of hole : 0.3 mm ( 0.012”) – 0.50 mm ( 0.02”) min. Tolerance (min) : 0.01 mm ( 0.0004”) – 0.02 mm ( 0.0008”).

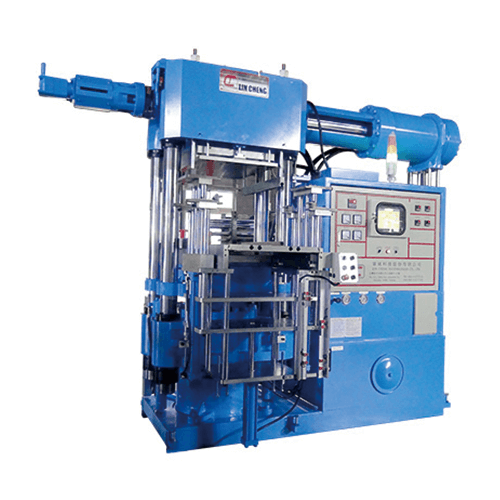

3RT Mold-Open Rubber Injection Molding Machine IRH-S3

Categories : Rain boot Injection Molding Machines

Mold opening design The 3RT surpasses the traditional top opening mold that can be used for the triple or four molds with the design of the opening mold and pushing out the mold in the between. The opening mold can be adjusted by the software with separate opening, separate pushing out the mold in between, continuous opening and continuous pushing out the mold in between. Injection volume control High precision optical ruler is adopted for precisely calculating and controlling. Design of rotary injection board Special designs for loading/unloading functions are provided. It causes no dead material in the injection nozzle. It is easy to clean the material. It is durable and the quality is stable. Safety design A high-tech infrared safety electronic sensor and automatic warning system are adopted to monitors the status of machine in order to provide extra protection to ensure the operation safety for operators. Hydraulic system Design Hydraulic system Designed by proportional pressure and flow ratio, which is steady, quiet and low frequency of malfunction. Two shafts can be operated simultaneously.

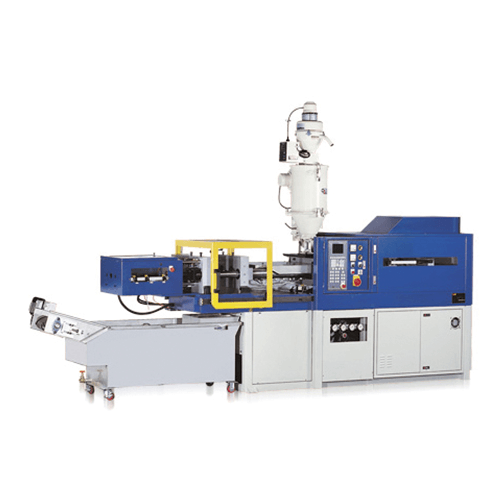

High Speed Plastic Heel Injection Molding Machine

Categories : Hydraulic Clamping Injection Molding Machines

● Rapid, high-precision direct hydraulic clamping system. Automatic needle loading, multistage ejection setting. ● Two adjustable nozzles with hot runners, molding 2 heels without runner in one shot.

Fiberglass Products Forming Machine

Categories : Compression Molding Machines

• Down stroke design with lower working height. • Double stations with the sliding carts increase productivity. • Sliding carts with position pins to secure working safety.

Atom- Horizontal Plunger Type Micro Injection Molding Machine

Categories : Horizontal Injection Molding Machines

● The best choice in micro injection products. ● New design patent-IPIS (Interchangeable Plunger Injection System). ● Plunger Type Injection can highly save runner resin. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Intelligent program controller makes injection easier. ● The shortest injection molding machine, the length of Atom100 only 1.9 meters. ● Precise energy-saving hydraulic system.

Heat Transfer Film for PE Materials

Categories : Films

All kinds of PE plastic products can use heat transfer, some composite materials like HDPE and LDPE, also can use too. as long as the surface is smooth and flat, the design and product can be perfectly combined. Heat transfer film has many function which direct printing doesn’t have. Using heat transfer film and heat transfer machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

Rear Transfer Injection Type Rubber Compression Molding Machine

Categories : Compression Molding Machines

Special for nylon cord retread tire with high temperature or second curing for tire with low temperature. With loading and unloading platform to save labor handling.

PP Blown Film Machine - HFPP

Categories : Blown Film Extruders

Water cooling system makes glossier and more transparent PP film for food or garment packing.

ENS Series-Accumulator type

Categories : Automatic Blow Molding Machines

Accumulator type - Design for big size products, something like automotive parts, hospital bed, mobile toilet...etc. Taking out robot is optional.

Supersize Blow Molding Machine

Categories : Extrusion Blow Molding Machines

Supersize – Accumulator Die Head Type Blow Molding Machine Supersize accumulator blow molding machines can produce the biggest blow molded products such as: Sports equipment Household products Packing vessels Water tanks and any kind of large size article. The accumulator die head is designed with a two heart-shaped flow channel welded line-free to increase the strength of the production.

Manual Feeding Transfer Injection Molding Machine

Categories : Rubber Injection Molding Machines

Features Injection volume control High precision optical ruler is adopted for precisely calculating and controlling. Design of rotary injection board Special designs for loading/unloading functions are provided. It causes no dead material in the injection nozzle. It is easy to clean the material. It is durable and the quality is stable.

PRECISION HYDRAULIC AUTOMATIC DIE-CUTTING MACHINE/4COLUMU TYPE CSS-603

Categories : Cutting Machines

Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance. 4 steel posts design instead of guide-ways for punching movement and equipping linear guide-way for the front & rear feeders. The unit performs precisely, stably, quietly, nimble and powerful. lt'sconvenient even for the use at the upstairs of a factory. Cutting depth can be precisely set up to a tolerance of 0.008 mm. Through the use of the longwearing special designed steel plate to replace conventional cutting board, can prolong lift of cutter and obtain better cutting quality and efficiency Processed item may be full or half cut-off. ltems with adhesive may be used as well Products are free from rough edges. The machine is equipped with a protecting device to ensure safety of people and the machine. Automatic cooling system and full-auto cutting device are available for additionally purchase and fitting. Designed in high-precision construction, this machine can be used to perform full-cut and half-cut fabrication tasks. Up/down punching travel uses four high-rigidity guide poles, with linear rail designed for the feeding mechanism. Two-step pressure control to achieve flexible and lower noise operation. It is suitable for multi-level factory buildings. Automatic cutter adjusting mechanism can perform automatic adjustment according to the desired setting, providing 0.01mm accuracy (0.001mm optional). High-precision german steel plate is used to achieve higher durability and wear free operation. This machine uses advanced and durable hydraulic system and electronic control circuits. The machine is equipped with protection device to ensure the safety of the operator and the machine. (with CE optional)

Polypropylene - PP1200G15

Categories : PP Resin

Glass fiber 15% reinforced. Application: Fan blades, Hand tools, Gardening tools, Sports equipment, Home appliances parts, Medical rehabilitation equipment, O.A. Office components.

Rubber Back-Injection Molding Machine

Categories : Rubber Injection Molding Machines

Rubber Back-Injection Molding Machine Nature rubber Rubber of metal boned parts Oil resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber

Gear Coupling

Categories : Gears

(1) Crowned tooth allowed larger tolerance in shafts and higher loads. (2) Special hardening treatment W/high strength and anti-abrasiveness. (3) Closed type coupling--easy lubricate & anti dust as well as no leakage. (4) The type of TIEN YI GEAR SHAFTS COUPLINGS had been successful the first processing, it must be done the second procedure heat treating again according to material. And it were given them more rigidly precise, increasing stronger tenacity. At last removing gravitation by striking-ball bearing when those steps all finished.

Motor with Gear Box

Categories : Motors

AC Small Motor with Gear Box -K Series】 This is a AC small motor combined with a gearbox. The motor is from 6W to 150W, and is used with the gearbox. The standard ratio of gearbox is from 1/3 to 1/180. If the gearbox ratio does not meet the requirements, you can replace the gearbox simply. The products are divided into single-phase motors equipped with capacitors or three-phase motors. The installation is simple and easy, so they are mostly installed in conveyor belt, packaging machine, food machinery, pharmaceutical machinery, automation machinery and other equipment. You can also choose AC small motors certified by UL or CE standards.

Onion Leno Bag Laminating Machine-TY-LMLB Series

Categories : Extrusion Lamination Machines

The main functions of the LMLB series can be made of two kinds of film at the same time. First is onion mesh cloth and printing leno through the lamination for bonding in the middle. Second is to laminate the film about 70-100 mm wide at the side, and this side film will do hole-punching process and used as auto filling and packing.

Lamination Line (Woven Sack)

Categories : Extrusion Lamination Machines

Lamination application for tubular woven fabrics. High level of coating technique provides smooth and even coating surface, which reduces material waste, while maintaining highest quality of coated fabric.

plastic shredder SP-420 / 60205

Especially for bulky plastic products. Eliminate the disadvantages of traditional high horse power crusher.Also for cracking unusual objects,waste tyres,logs,sleepers,etc. ● 2-shaft,claw-cutter breaker has the best ability to shred anything with low noise,vibration free. ● Auto reversible equipment to prolong the life of machine.

EXTRUDER FOR PVC/TPO SOFT FILM

Fruitive International Co. helps consult and design different types of PVC / TPO soft products extrusion line for customers and suitable for a variety of PVC / TPO soft products production. It is applied to products such as PVC tablecloth, shower curtain, tiles backing, transparent film car decorative, flloring, TPO tablecloth, printed film and so on. The extruder and calender unit that consists of rollers is also the core equipment of a production line. Hence, this is important when choosing the right products. We always make every effort to assist our clients to select the requested products in regarding to some technical aspects such as length and diameter ratio of the extruder, the width and the material of the calendar roller with the maximum capacity in order to meet the aimed production capacity and product demands. We achieve making the best thickness contribution by adopting the technology of moving rollers, roll bending, and other means. It is also an option to equip the most up-to-date full automatic control as well as the thickness monitor on our calenders.

Wrap-around Labeling Machine KWT-500-Serials

Categories : Labeling Machines

KWT-500 serials are manufactured for round containers.

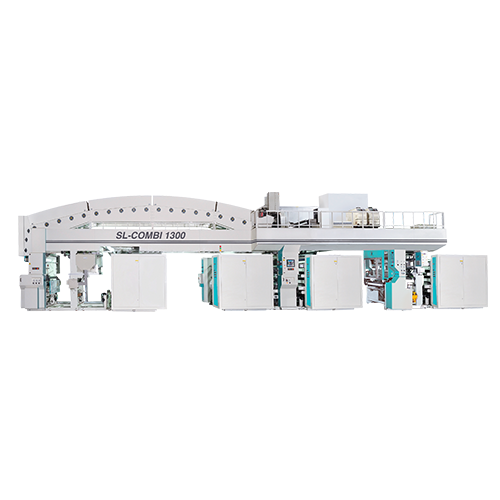

SL-COMBI-The multi-functional coating and laminator

Categories : Industrial Lamination

SL-COMBI ( The multi-functional coating and laminator) The SL-Combi is a versatile machine, combining a series of different coating and lamination techniques. Available for duplex or triplex lamination and up to muti-layer lamination inline with different coating or printing process. The machine could work with solvent, solventless and water based compounds. If you are looking for multi coating and laminating solution, this is the press for you to customize. KYMC

HP-42HD

Categories : Blown Film Extruders