Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Horizontal Blow Molding Machines

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome. Co-extrusion application is the advanced technology by the leading brand: Full Shine.

HEAVY-DUTY BLOWN FILM MACHINE

Categories : Blown Film Extruders

Film width 2000 ~ 4000mm, for general packing and agricultural Hutch. Heavy duty construction, take up tower. Automatic surface winder with uploading device. Swing type manual screen changer. LDPE / LLDPE Heavy Duty Big Size Blow Film Machine. Screen changer of swing manual type. Extruding die of single spiral channel gives even and smooth flow pressure, Air ring of dual orifice design ensures ultimate cooling. Heavy duty steel structure takes up tower. EPC (Edge Position Controller) Fully automatic big roll type single winder or back to back auto winder.

Automatic-Blow-Molding-Machine-H Series

Categories : Automatic Blow Molding Machines

Our versatile and efficient plastic blow molding machine can produce a wide variety of products, from 5ml to 10L, with single-station or double-station configurations, monolayer or multi-layer, and 1 to 6 cavities. It is compatible with PE, PP, PETG, PVC, ABS, PA, PS, and co-extrusion materials. An optional view stripe line is also available. This machine is a great choice for businesses that need to produce high-quality plastic products with precise dimensions in a cost-effective and efficient manner. ● Apply for single station/ double station ● Production volume: from 5ml-10L ● Mono layer and multi layers are available ● Cavities: 1~6 cavities ● Apply for PE/PP/PETG/PVC/ABS/PA/ PS/ Co-extrusion material ● Option: view stripe line ● Support: Hybrid system, Parison control, auto deflashing, turn key solution

PET Blow Molding Machine - Wide Mouth Bottle

Categories : Horizontal Blow Molding Machines

Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

Automatic Blow Molding machine With Pneumatic Clamping System- A Series

Categories : Automatic Blow Molding Machines

This type is the pneumatic-clamping blow-molding machine, suitable for making popsicle (ice-lolly) & various small-size bottles. Extrusion is driven by the inverter motor with pulley-drive gear box. Innovative design for double die head production. Mold clamping is driven by pneumatic system, available for upgrading to hydraulic-drive system (Option). Carriage movement is the swing movement for taking the finished products from the front of the machine. Independent electric control box with simple control panel. Simple-type blow molding machine, suitable for low and initial blow molding machinery investment.

Automatic Blow Molding machine- O Series

Categories : Horizontal Blow Molding Machines

Single Die Head or Double Die Heads and Single Station Type, Suitable for View Stripe Containers, Equipped with Auto Conveyor, and Leaking Tester for Quality Supervision.

Auto Batch Mixing Machine

Categories : Vacuum Forming Machines

Suitable for small to medium scaled foam factory. Block foaming machine consists of mixing system with moving forward and backward device. Metering system with re-circulation flow to control chemicals which are dosed from the chemical storage tanks through pipe work and pneumatic injection valve systems into the mixing barrel. As soon as the mixing time elapses, the hatch of mixing barrel will automatically open to load the mixture smoothly into the mold and close the hatch then can draw it backward to its original position automatically. No need to clean the mixing barrel between each shot.

Auto Batch Vacuum Foaming System SA-1BVF

Categories : Vacuum Forming Machines

The SA-1BVF can be used with an existing auto batch foaming machine or with SUNKIST's own SA-1B, SA-1BS, SA-1BM and SA-1HA. After the mixture is loaded into mold box, the mold box is moved into this chamber via a carriage. After the mold box us placed inside the curing chamber, the door of the chamber automatically closes and shut tightly. An operator can then adjust the pressure inside the chamber with the control panel. The quality and physical properties of the foam that is formed will be affected when the pressure is changed, ie. the volume of the foam size will increase, foam tensile strength will also increase dramatically, and the hardness of the foam will change. This machine is environmental friendly, reduce the amount of chemicals used and reduce the fire risk.

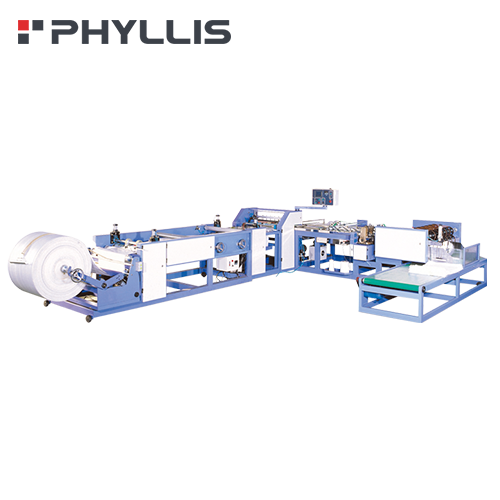

Conversion line (Gusseting-Cutting-Sewing)

Categories : Cutting Machines

The new generation of woven sack conversion line for bottom-sewn sacks is suitable for coated and uncoated woven fabric, and BOPP film laminated fabric. With great variety of options, a wide possibility of applications is brought for the customer.

High Speed Automatic Bottom Sealing Bag Making Machine

Categories : Plastic Bag Making Machines

HIGH SPEED AUTOMATIC BOTTOM SEALING BAG MAKING MACHINE

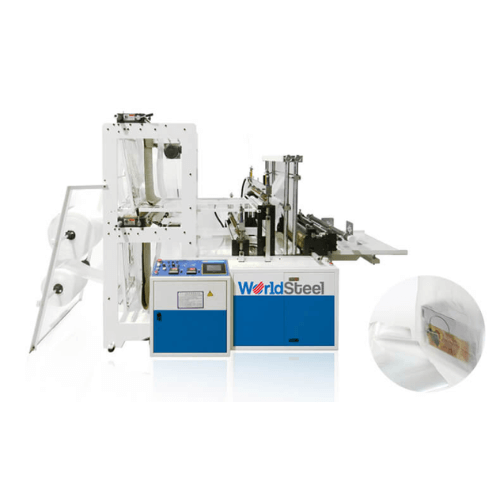

Perforation And Slitting Machine

Categories : Slitters and Rewinders

The World Steel perforation and slitting machine is the best choice when it comes to customizing your film for packaging and agricultural applications. It is able to process a range of types of single layer polypropylene films and optional equipment can be added to improve production accuracy and quality. Some of these options include: PLC device to monitor and control inputs and outputs, a scrap coiler to collect your waste film, core cutting machines for paper tube preparation and a specialized hot needle wheel for pinpoint accuracy.

Automatic Servo C-Folding Perforating&Winding Bag Making Machine-RFCW1-SERVO-Series

Categories : Plastic Bag Making Machines

REE series is equiped two photo-cell & electric-magnetic clutch & brake, suit able for running two tracks of the printed film.