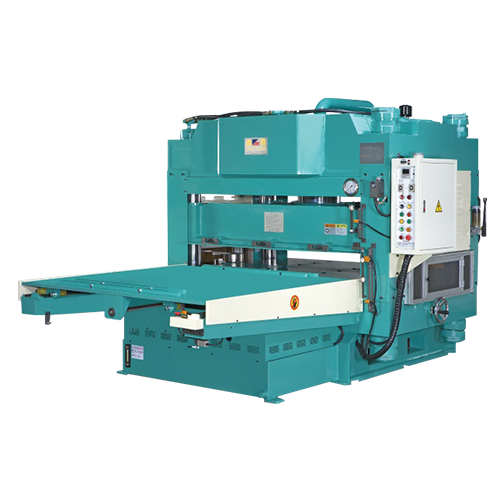

Precision Hydraulic Four Column Type Automatic Feeding Cutter - CSS-806A

Categories : Cutting Machines

Precision Hydraulic Four Column Type Automatic Feeding Cutter

Auto Laminating Machine ALM-800

Categories : Cutting Machines

Synchronized automatic glass handling mechanism to speed up operational efficiency. Unique, special, patented pattern film laminating mechanism, to ensure no air bubbles after lamination process. Automatic cutting and partitioning mechanism to cut and partition laminated work pieces. Laminating length and speed can be programmed and adjusted to suit actual requirements. Optional single-side or double-side protective films can be laminated to suit actual requirements. With pattern paper recoil function to automatically recoil the pattern paper. Compatible with glass automatic feeding and automatic material take-up system.

High Speed Precision Vertical Injection Molding Machine-YQ Series

Categories : Vertical Injection Molding Machines

• Vertical four-pillar vertical clamping, with vertical injection. • The square pillar design comes with large mold size. The space within the column allows customers to install devices of automatic embedding and removing products. This allows automation for the whole machinery. • Big L / D ratio of screw, plasticizing evenly, suitable for injection molding of engineering plastics. • High standard computer control system with high precision injection pressure and high response injection speed. The quality is more stable for high-precision embedded injection molding products. • 1S single sliding: After mold opening, the lower mold will automatically slip in front of the operator for facilitating embedded molding operation. • 2S double sliding (Alternating double sliding): One mold for injection molding, another mold for taking out and putting on embedded parts operation. • 2SL double sliding (90°Alternating double sliding): One operator can operate independently. One mold for injection molding, another mold for material taking and putting on embedded parts. The two slidings are intersecting at 90 degrees, which can lower the production cost, and enhance the performance. • Able to combine automation and the high-speed injection can effectively enhance the production capacity. • A variety of circuit design (half closed servo hydraulic or high speed injection) to meet the customer’s requirements.

Thermoforming Packaging Machine

Categories : Contact Heating Thermoforming Machines

Thermoforming Packaging Machine from Jaw Feng Machinery Co., Ltd. is made of stainless steel, in line with food hygiene and safety. Durable transmission chain can clip the film more than 2 million times. Servo motor provides precise and fast forward. Multi-lingual PLC touch screen. Able to work with automatic filling machine, date injecting, date thermal printing, film easy to tear, water cooling machine, etc. Simple, easy change over for die sets; Custom die size. Automatic notice for insufficient film supply. High-speed production can reduce considerable labor costs. It can be used to package powder, paste, solid and liquid materials. We also offer a variety of options for this machine.

THERMOFORMING PACKAGING MACHINE

Categories : Contact Heating Thermoforming Machines

Thermoforming Packaging Machine from Jaw Feng Machinery Co., Ltd. is made of stainless steel, in line with food hygiene and safety. Durable transmission chain can clip the film more than 2 million times. Servo motor provides precise and fast forward. Multi-lingual PLC touch screen. Able to work with automatic filling machine, date injecting, date thermal printing, film easy to tear, water cooling machine, etc. Simple, easy change over for die sets; Custom die size. Automatic notice for insufficient film supply. High-speed production can reduce considerable labor costs. It can be used to package powder, paste, solid and liquid materials. We also offer a variety of options for this machine.

PSM - 8 Cup & Tray Automatic Filling & Sealing Mac

Categories : Sealing Machines

Cup dispense-filling-sealing machine be demanded on high speed and availability. High accuracy assembly construction requires to satisfy customer's product can be achieved perfect sealing and CIP system available to achieved hygienic required. Research and innovation more harmony human operation environment from construction design until assembly works all requires consistence and useful to reduce customer's machine breakdown cost. Jelly, pudding, cream, cup water, cup noodles, snack, soup, ice cream, rice cake, cosmetic, juice, and other daily foods.

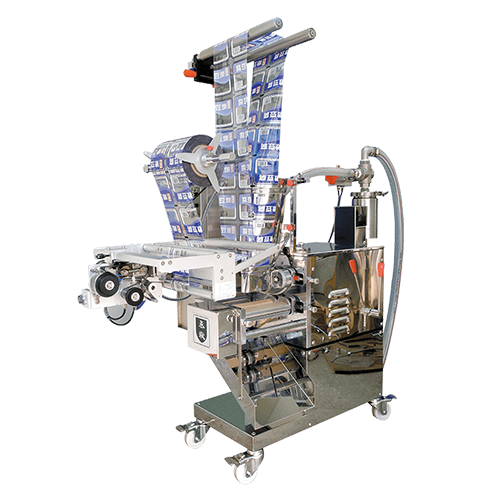

Liquid & High Concentration Sauce Packaging Machine - TYPE-857

Categories : Liquid Packaging Machines

• Application Products : Liquid : tea、juice、water、shampoo、soy bean sauce、bathing lotion、liquid sauce and other pure substance. Density : Tapioca、cream、jam、BBQ sauce、meat sauce、salad、facial lotion、chili、tomato sauce、butter and the similar. • Features : Automatic bag making → measuring → filling → sealing → cutting →finished products conveying. • Packaging Materials : Heat sealable laminated film (such as : Nylon + PE,OPP+PE,Alum foil + PE & other similar beat sealable film)

Horizontal Bag Filling & Sealing Machine

FEATURES : 1. Design for the most versatile packing applications. 2. The outer structure of machine is shielded with SUS304 stainless steel for ease of cleaning and maintenance. 3. Fitted with automatic weighing, filling machines, date corder, and conveyor (optional) to suit various materials. 4. Rated weigh within 2000 Grams per bag. APPLICATIONS : Juice, Jelly, Plum Jelly, Yugum, Red bean paste, Tea bag, Coffee bag, Powder, Granule, Melon seeds, Beans, Candy, Detergents, Mask, etc.

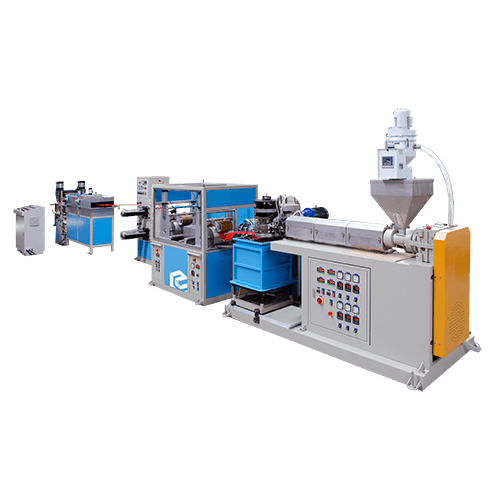

Net Extrusion Machine Line

The Everplast mesh production line is designed for high production demands. Provides high productivity, high precision, and excellent mesh surfaces. The screw is precision machined from high-quality alloy steel SACM-1 and nitrided to provide high performance and durability, ensuring high extrusion capacity and automatic temperature control. The entire machine's movement is controlled by a high-efficiency controller, making it easy to operate.

Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Horizontal Blow Molding Machines

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome. Co-extrusion application is the advanced technology by the leading brand: Full Shine.