PET Stretch Blow Molding Machine - TEM06S2

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

PET Stretch Blow Molding Machine - TEM04M1

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

Stretch Blow Molding Machine PK-2PSB

Categories : Automatic Blow Molding Machines

Production Volume:200ml~5,000 ml Multi cavities: 1~2 cavities Specialize for the PET Driven Model: Hydraluic system

PET Stretch Blow Molding Machine - TEM08S2

Categories : Automatic Blow Molding Machines

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. ● The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. ● Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. ● The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. ● Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. ● With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. ● Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. ● The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. ● Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

Semi-Automatic PET Stretch Blow Molding Machine - FS 1000HD

Categories : Automatic Blow Molding Machines

One Heating Machine Two Stretching Machine. -Small size and unoccupied space. It could produce 300c.c.~20Liter PET bottles and suitable for various bottles. -Semi-auto PET Stretch Blow Molding Machine is suitable for limited production but various products. -This type of machine can produce plastic containers for the widest range of product's capacity. Moreover, machine's size is small and occupies few space.

Dual Platen Injection Molding Machine

Categories : Injection Molding Machines by Platen

As a large tonnage injection molding machine, it can saves up to 20% of the machine floor space. (foot print) • Automatic mould adjustment saves on mould-changing time.

Rotary Cutter For Wide Neck Drum

Categories : Cutting Machines

-Rotary Cutter-For Open Top/Wide Neck Drum. -Increases the Production Quality by Automatically cutting the drum's neck.

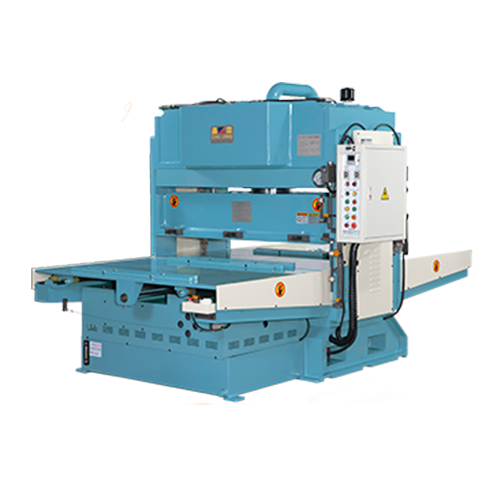

HIGH PRECISION HYDRAULIC CUTTING PRESS CSS-607

Categories : Foaming Machinery

The Structure Of Press Body Is Made By Special Steel Shaped Materials That Features Pressure-Resistant Function To Maintain A Permanent Plane, With Its Integrated Shaping Of Punch And Slide To Fully Shows A High Resistance Of Wear And Tear, Excellent Strength And Stable Pressing That Would Help Prolong The Service Life Of The Mold. The Cutting Tool Can Be Used With Laser Cutter For Either Pressing Or Die Pressing, Thus Making Product No Burrs And Enabling Clear Angles. The Blowing Device Can Be Worked Further With Mechanical Action, One Punch And One Blowing Subsequently To Absorb Automatically The Well-Cut Finished-Goods That Makes An Easy Access And Safe To Take Feeds, Along With An Installation Of The Almighty Grooved Base Plate, The Mold Locking Is Convenient And Rapid. With A Device Of Fixed-Point Type Pedal Switch, It Shows Up A Mature Technologic Design For Industrial Use. With Its Semi-Automatic Knife Mold Design, It Enables Operators An Easy And Safe Operation.

PRECISION HYDRAULIC AUTOMATIC DIE-CUTTING MACHINE/4COLUMU TYPE CSS-603

Categories : Cutting Machines

Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance. 4 steel posts design instead of guide-ways for punching movement and equipping linear guide-way for the front & rear feeders. The unit performs precisely, stably, quietly, nimble and powerful. lt'sconvenient even for the use at the upstairs of a factory. Cutting depth can be precisely set up to a tolerance of 0.008 mm. Through the use of the longwearing special designed steel plate to replace conventional cutting board, can prolong lift of cutter and obtain better cutting quality and efficiency Processed item may be full or half cut-off. ltems with adhesive may be used as well Products are free from rough edges. The machine is equipped with a protecting device to ensure safety of people and the machine. Automatic cooling system and full-auto cutting device are available for additionally purchase and fitting. Designed in high-precision construction, this machine can be used to perform full-cut and half-cut fabrication tasks. Up/down punching travel uses four high-rigidity guide poles, with linear rail designed for the feeding mechanism. Two-step pressure control to achieve flexible and lower noise operation. It is suitable for multi-level factory buildings. Automatic cutter adjusting mechanism can perform automatic adjustment according to the desired setting, providing 0.01mm accuracy (0.001mm optional). High-precision german steel plate is used to achieve higher durability and wear free operation. This machine uses advanced and durable hydraulic system and electronic control circuits. The machine is equipped with protection device to ensure the safety of the operator and the machine. (with CE optional)

Precision High Speed Hydraulic Automation Cutters-CSS-202

Categories : Foaming Machinery

● The machine adopts two-hand button, safe operation, fast, smooth, strong pressure, no noise, no vibration power, upstairs, downstairs plant can be used, low failure rate, improve production efficiency. ● Die automatic setting: Stroke is simple, fast and accurate, extending the life of knives and knives. ● automatic lubrication system: The use of mechanical parts can be automatically refueling, to ensure that mechanical damage, permanent security precision. ● Can be arbitrarily adjusted to determine the single layer. ● This machine is equipped with brake device to ensure the safety of personnel. ● special models can be customized.

Precision Hydraulic Double-Sided Auto Feed Cutter CSS-806

Categories : Foaming Machinery

Both double-side and single-side operation, time and manpower saving, one machine for two purposes to give excellent effect of production. Double-side pressure and touch-type electronic counter watch are separatively deviced, so different sizes of product can be adopted. Super precision oil way design, silent for performance, stable location for each action, to increase the service life of parts and tool mold deviced with cutting board rotary table, the consumption of cutting board can de reduced. Body frame adopts high tension steel plate under stress relief process for long application without being deformed.(We welcome any special size from buyer).