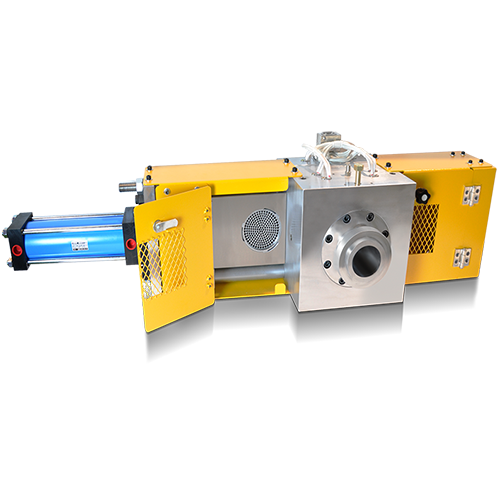

Screen Changer

Categories : Screen Changers / Filters

HYDRAULIC SLIDE PLATE Hydraulic system, easy for operation. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : for extrusion products such as sheet and films. Hydraulic system, easy for operation. NON-STOP SLIDE PLATE Streamline and smooth channel for easy clean and little polymer stagnation. Interruption free and few bubbles caused by filter replacement. Hydraulic system with nitrogen accumulator for easy and fast operation. Fast slide plate movement for non-stop production. Materials : most polymer. Application : for extrusion products such as opitical, sheet and films. DUAL SLIDE PLATE Continuous production process. Interruption free filter replacement. Hydraulic system is driven by solenoid valve for easy operation. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : suitable for sheet products. DUAL PISTON Continuous production process, air does not enter the production process. Interruption free by filter replacement. Hydraulic system is driven by solenoid valve for easy operation. Optional auto-venting system. Can be equipped with a fully automatic exhaust. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : suitable for optical, sheet, film and other products. LARGE FILTRATION Continuous production process. Special venting design that no air enter the process during screen changing. Hydraulic system is driven by solenoid valve for easy operation. Optional auto-venting system.Can be equipped with a fully automatic exhaust. Can be equipped with a fully automatic exhaust. The filter area is about 2~5 times larger than the Dual Piston. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : suitable for granulation, sheet, film and other products. BACK-FLUSH Interruption free filter replacement. Low pressure difference for stable and continuous production during filter replacement. Maintain 75% filtering area during filter replacement and backwash. Safety cover design improves operator safety. Automatic backwash and exhaust function for cutting filter replacement loss, operating requirements and scrap reduction. High wear-resistance, high pressure resistance, high-precision filter design provides effective filtering area and filter quality. Materials : most polymer. Application : suitable for recycle, granulation, packing tape and film. MANUAL WITH LEVER GEAR Easy operation with lever gear. Energy saving without driven system. Easy to clean when changing materials or colors frequently. Machine shutdown before filter replacement. Machine shutdown before filter replacement. Application : usually applied on sheet line, blow line and lab machine. SELF-CLEANING FILTER Interruption free filter replacement. Large filtering area, applicable with a larger mesh count. Manual back wash. Energy saving without driven system. Materials : most polymer. Application : usually applied on sheet , lamination and film line. CANDLE TYPE Compact mechanical design for higher mesh count to extend filter time. Manual network change, no hydraulic system. Adjustable pressure control during production to increase the effect of mixing in the screw. Application : applied on Lamination and film line.

Automatic High Speed T-Shirt Bag Making Machine-DP-HEP-HEEP-SERVO-Series

Categories : Plastic Bag Making Machines

● Dual in-feeding device with sensor control(DP-HEP-201 only single) ● With photo-cell for print registration ● Hot cutting & sealing device with down-heating ● Dual double hot-pin bookbinding device

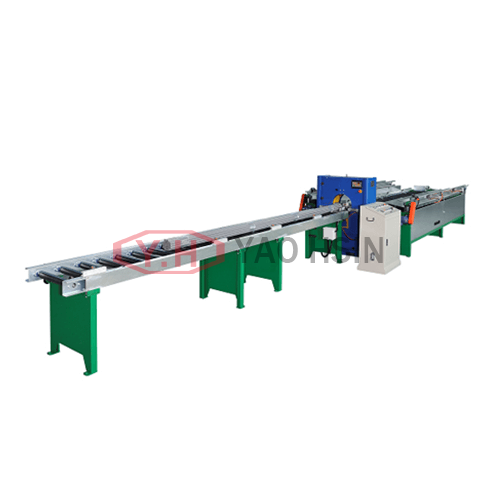

HIGH-SPEED STEEL MOLD CUTTER HSP-12

Categories : Foaming Machinery

Innovative Feed Mechanism: In which, the auto up/down feed system is designed for the height of the molded material. Superb And Stabilized Dead-Point Accuracy: For which the dual-axle synchronized mechanical structure is designed to achieve higher lower dead point stability. High-Precision Depth Adjusting Mechanism: Which uses left/right synchronized fine-tune unit to achieve 0.01mm of fine-tuning accuracy. Parameter Saving Function: To name and store relevant parameters after being set. Molding Machine On-Line Function: To carry out synchronized control with other molding machine through on-line operation. Automatic Lubrication Mechanism: In which, the automatic lubrication mechanism is designed to reduce the daily maintenance work.

for Electrical Injection Molding Machine- TGSM Series

Categories : Gearboxes

Features: Save power & suitable for big tons of output in production High torque, High rotation speed, Less abrasion & low noise. Lubrication System: Oil Forced Type Reach AGMA 10 LEVEL & UP Gear material: SCM420 Shaft: SCM440 Stable output during injection, Power starts when the material has been delivered and stops automatically when no material is detected Motor Flange & Input Shaft customized available as per request.

Multi-Axle Auto Film Bonding Machine AFC-700LE

Categories : Cutting Machines

Patented Bonding Mechanism: In achieving higher bonding accuracy and without air bubbles. Fully Automatic Tension Control System: The tension of materials for each axle is controlled in an automatic way. Servo Transmission Control: Dual-Axle servomotor is used to achieve synchronized alignment control. Diversified Size Option: The parameter fine-tuning can be executed according to the characteristics of different materials. High Clean Bonding Environment: Which meet high-cleanliness bonding space requirements in providing higher Y-Rate. Unique Material Handling Techniques: Which is designed according to the characteristics of optical film to avoid scratching the material.

THS 850/950

Categories : Industrial Robots

•Vacuum gripper circuits. •Automatic mode micro-modify. •Automatic stacking/palletizing. •Pick up parts from core/Cavity side of the mold. •Reject parts/alarms/operation history. •Stand by above mold,waiting outside mold. •Bad count/break down history/operate record.

Secondary Packaging - Cartoning - CSC-50

Categories : Cartoning Machines

The cartoning equipment applies the vertical semi-automatic production operation. The equipment is suitable for more types with medium capacity products

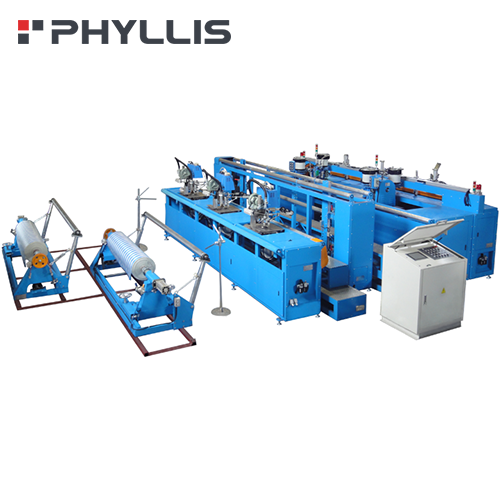

Tarpaulin Making Line (Automatic Line)

Categories : Film and Sheet Extrusion Lines

Our automatic tarpaulin making line is designed to weld multiple rolls together with 2 side eyeleting, and cut to desired length simultaneously.

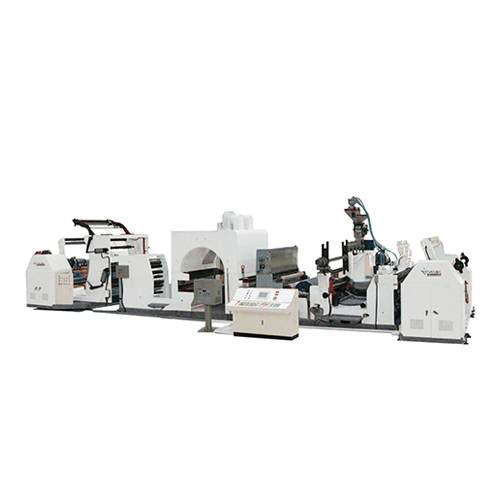

Extrusion Lamination Machine For Release Paper, Wrapper

● Unwinder and winder adopt duplex air shafts, auto alternant, splicing and roll change. ● Auto roll change and splicing with no speed reduction. ● Attach a corona treater as a standard equipment to ensure laminating quality. ● Attach a detector to enhance steady winding. ● Whole machine is synchronously controlled by PLC programmable, and easily operated through human machine interface.

HIGH-ACCURACY ROLL-TO-ROLL AUTOMATIC FEED CUTTING MACHINE TRC-350SP

Categories : Foaming Machinery

Double-Axle Synchronous Feed Mechanism: Enhances the production speed and Yield Rate through double-axle synchronous feeding. Well-Designed And Stabilized Bottom Dead-Point Accuracy: Uses the patented Bottom Dead-Point Mechanism exclusively developed by TRURAN to achieve +/-0.005mm of repeated positioning accuracy. High-Accuracy Depth Adjusting Mechanism: Uses high-accuracy mechanism to achieve 0.01mm of fine-tune accuracy (0.001mm is for optional). High-Efficiency Boosting Circuit: Reduces over 30% of power consumption as compared to conventional circuit. Photoelectric Material Flexibility: Uses as the dedicated moving system according to the material characteristics. Unique Material Moving Mechanism: High-stability servo control system is used to avoid contaminating and scratching the material. Automatic Lubrication Mechanism: The entire machine uses Automatic Lubrication Mechanism to reduce daily maintenance work. Waste Recovery Mechanism: The System will recover the waste of cutting automatically to save space, while enhancing the operability.

Disc Coupling

Categories : Gears

(1) NO-LUBRICATION REQUIRED: No lubricants are needed and no noises or wear and tear produced because there is no sliding or friction. (2) MAINTENANCE-FREE: ”LEAVE IT FOR GOOD AFTER INSTALLATION” It lasts forever as long as is used correctly. (3) LIGHT WEIGHT W/HIGH TORQUE: By operations, it is available in a wide range; it can be made of aluminum alloy to reduce the weight. (4) LARGE OFF-CENTER ALLOWED: With large range of off-centering, it can be used flexibly in all kinds of transmission systems. (5) SUITS HIGH-TEMPERATURE APPLICATIONS: All-metal-pars construct makes it suitable for high temperatures. (6) BACKLASH-FREE: WITH GOOD TORSIONAL RIGIDITY Perfect for axial rotation that requires accuracy and machines with phase-control. (7) CAN BE USED IN EVEN HIGHER SPEEDS: It is highly balanced due to being backlash-free and light weight. (8) EASY TO INSTALL: Comprising small number of pasts and being compact, it can be installed/uninstalled quickly. (9) ROBUST STRUCTURE AND HIGH SAFETY COEFFICIENT: With load stress kept at low standard, it works with very high safety coefficient. (10) AUTOMATIC PROTECTIVE DEVICE: In case of damage, an automatic protective device rotates via pads.