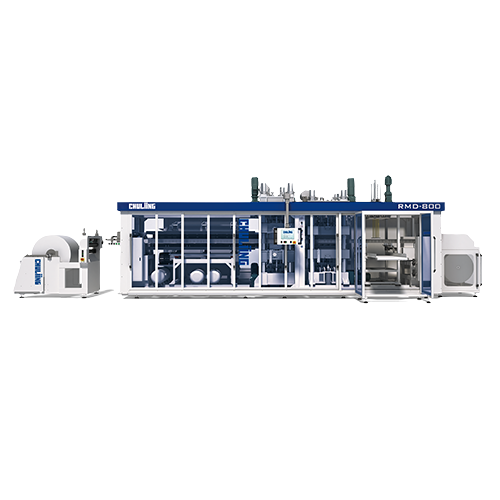

European System Pressure Forming Machine (Forming, Cutting, Stacking 3 Station in On e Machine) RMD-800

Categories : Vacuum Forming Machines

European design, intelligent control, lightweight. Convenient mold change, quick, suitable for smaller quantities and diverse production line manufacturing. High rate of movement, low failure rate, reducing the costs associated with machine errors. Innovative intelligent system, which gives the operator an easy to use interactive interface which reduces the opportunity for human error. Remote obstacle monitoring and instantaneous data processing allows rapid problem correction. High-precision cutting technology, allowing high-speed control, low machinery wear and exceptional cutting performance. Adjustable, automatic stacking technology, which remembers your last production needs.

C type Injection molding machine with rotary table

Categories : Rubber Injection Molding Machines

C type Injection molding machine with rotary table With C type configuration to have easy operation access. Rotary table design with two molds shifting to increase production efficiency. Feeding rupture detect to prevent process from rubber shortage. With external heating platen to maintain mold temperature. Automatic operation can be realized by having the auto de-molding device and cleaning system. Rotary table is driven by servo motor which can offer multi-station production with different positions stop. User-friendly color touch screen interface to facilitate all parameters settings and observation. Option available: Auto de-molding device and cleaning system. OPC-UA configuration to connect with MES/ERP system. With the Cold Runner Block (CRB+) control system.

Vertical Electric Injection Molding Machine-YE-50V

Categories : Vertical Injection Molding Machines

A number of patented electric injection device Precision electric injection function Precision electric metering function Electric pedestal does not slide function Energy-saving hydraulic servo mold clamping function Accurate low pressure off mode protection function Energy-saving hydraulic servo thimble function Template rust plating processing Template parallelism fine tuning function Template low-top design With 8 T-groove, easy to fix the mold Thick template with high tensile guide posts Configuration template guide column anti-drip bumper sleeve Configure mechanical closing safety bars Configure mechanical shut-off safety electrical protection Open all the safety gates to stop the design Configuration key type safety door safety switch Configuration rail horizontal operation safety gate design Injection device can be flipped to maintain the factory accuracy to reduce the height of the handling method Injection closed loop feedback function Holding pressure switching point accuracy of 0.01mm Packing pressure accuracy of up to 0.1% High-speed rigid filling, to eliminate floating phenomenon Prevent the drawing function A variety of peripheral equipment chain function Equipped with peripheral equipment power outlet With robot centralized terminal block Hopper holder moving function Equipped with resin feed tube holder Equipped with adjustable height white iron trough Equipped with a perspective control water divider Equipped with cooling water quick connector The machine is neat and without any pipe exposure Than the same level of oil-saving 25% to 60% Than the same level oil machine to save cooling water 70% Equipped with 10.4 "color touch screen PID automatic temperature adjustment function Japan's Mitsubishi control system Equipped with wear-resistant material pipe

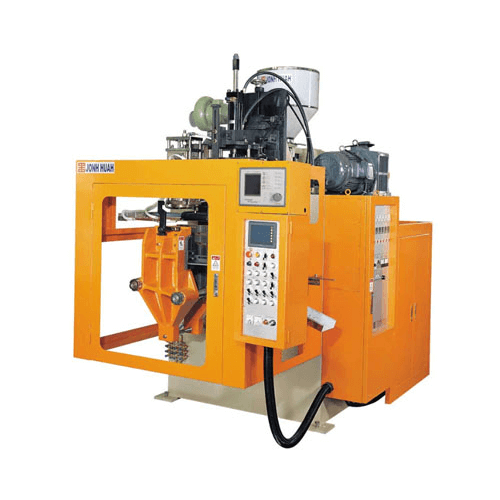

JS Series-Single Station

Categories : Automatic Blow Molding Machines

●Hydraulic type Plastic Blow Molding Machine. ●Automatic production design. ●Mold Open/Close/Move by cylinder. ●Gearbox drive extruder system. ●PLC control with Touch Screen for function, time, pressure...etc. ●Diversified parison knifes and multihead choices depend on the requirement. ●Proportional pressure hydraulic system. ●Especially for 2 liter bottle and 5 liter bottle.

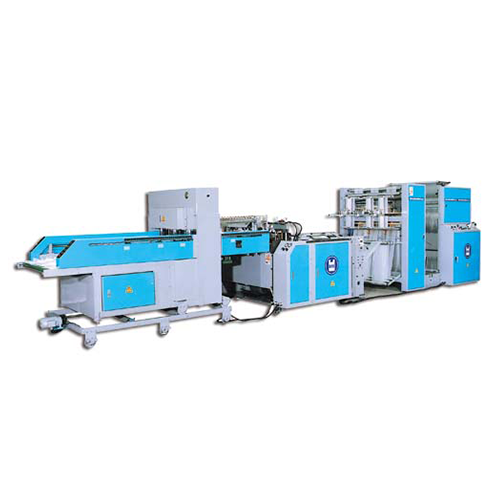

Automatic High Speed Hot Slitting T-Shirt Bag Making Machine-HEP-G3-150-Series

Categories : Plastic Bag Making Machines

● Special designed for huge production of non-tension sealed, printed T-shirt bags making. ● Programmable Logic Controllers are installed for easy operation and maintenance.

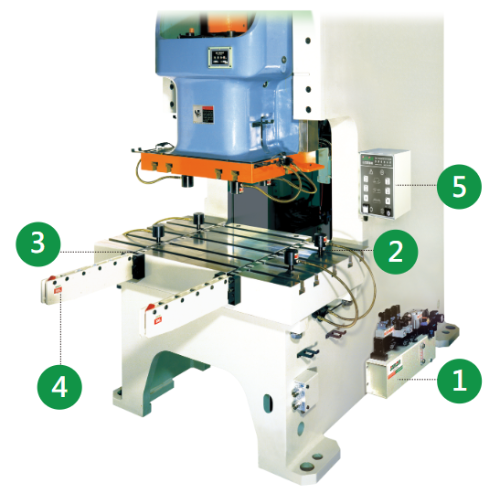

Quick Change Die System

Categories : Mold Changing Systems

It is an era for making high frequency of die changing with multiple patterns and small quantity. In order to save die changing time and ensure operational safety, it is just in time to apply Quick Die Change System. APPLICATION Press & Hydraulic Press Different Automatic Machine & Clamp System

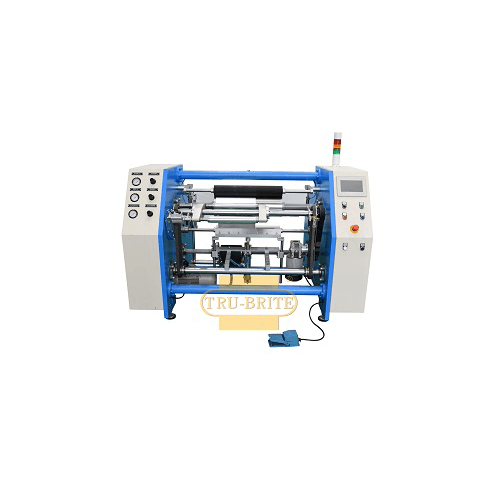

MULTIFUNCTION TWO-SHAFT TYPE SEMI-AUTOMATIC ALUMINUM FOIL & CLING FILM REWINDER (SRB-A-2S 20-50)

Categories : Slitters and Rewinders

SRB-A-2S, the two shaft type semi-automatic, multiple functions rewinding machine Suitable for rewind aluminum foil and PE, PVC cling film. The mother roll available width is from 200-500 mm. The finished paper core’s I.D. is from 25-50 mm. This model is carried a brake system, controls the brake power accurately. Users can check the data of brake output and single product weight anytime. SRB-A-2S is able to set prior deceleration points of every speed level. Users only need to adjust rewinding speed afterwards. Machine will regulate deceleration points automatically by the settings. It has automatic functions of cutting and fixed length feeding. Users will thread the material onto paper core more convenient. The whole machine is combined of electronic control, carried with electric motor system; enable more precise and quicker shaft-changing movements. While finished rewinding process, the rewinding shaft will back off by itself. Users can switch to the automatic mode which start machine automatically after shafts are pressed down. Automatic cutting, automatic shaft-changing and shaft pressing, users just need to load & unload products after press start button. Welcome to consult machine with us. We will at your service.

Twin Taper Screws With Two Rolls Sheet Machine (Rubber Sheet Performing Machine)

Categories : Dispersion Kneaders

This Machine For KNEADER、BANBURY Auxiliary Equipment, The Compound Mixing Discharge Feed Into Twin Taper Screw To Automatic Extrusion Sheet, Also Can Continuity Produce, The「Automation Continuity Sheet」Process Design, Can To Replace Mill「One People - One Machine」Conventional Process, Not Need Worker Operation, Increase Machine Automation Production Security And Convenient, Increase Property Added Value, It Is The Best Automation Produce Equipment.

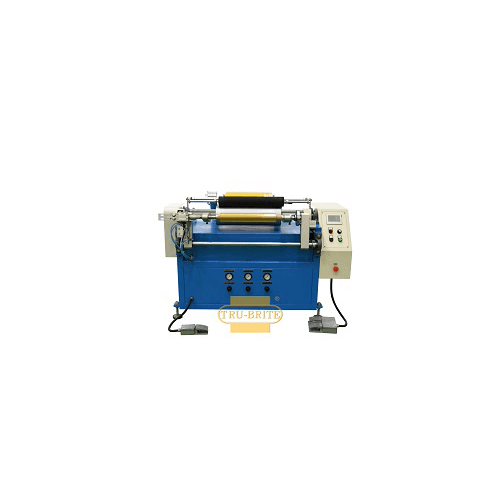

TWO-SHAFT TYPE SEMI AUTOMATIC CLING FILM REWINDER (SRS-2S 20-50)

Categories : Slitters and Rewinders

SRS-2S, the two shaft type semi-automatic rewinding machine. It specializes in rewind PE, PVC cling film. The mother roll available width is from 200-500 mm, and the finished paper core’s I.D. is from 25-76 mm. SRS-2S has a knob for adjust rewinding speed. Users can choose convenient functions. Such as automated start after press down the rewinding shafts; or changes shafts automatically. The PLC unit wisely assists user to run the machine. Machine is carried pedal controllers which have 4 functions: Mother roll chuck switch / finished paper core switch / rewinding shaft pressing switch / start switch. Various pedal switches, more convenient operations. Welcome to consult machine with us. We will at your service.

AUTOMATIC TRAY SEALER WITH VACUUM AND GAS FLUSHING

Categories : Vacuum Packaging Machines

Automatic Tray Sealer with Vacuum and Gas Flushing from Jaw Feng Machinery Co., Ltd. is made of stainless steel. Outdoor security vacuum cover. When electrical box is opened, it will shut down immediately. Can use multiple die sets and easy to change over, Multi-lingual PLC touch screen with a movable arm. Operate 360°. Every functions on the screen are presented in narrative, simple to understand. Vacuum / nitrogen, vacuum / skin pack, and sealed packaging. Offering lots of models to meet different sizes of trays. Able to work with date injecting, date thermal printing, labeling, aligner feeder, etc.

WINDER

Categories : Slitters and Rewinders

Winder is installed on the calender production line or on the end of production line that carries out exchange or rewinding various materials, in response to different winding requirement according to the products. Our winder adopt precise guidance and easy to operate. The speed is up to 200 m / min, the reel diameter is up to 1500mm, width is up to 6000mm. Some models are capable of reeling the upper side of films into the inner or outer roller. And after cutting the film into the desired specification, up to 3 rollers from the single spindle can be done. Processing with the drive motor and control system, the maximum tension precision at high-speed is guaranteed. We have a broad selection of winders for different product layout or custom. Automatic center winder (taping or Free taping type), automatic single roller surface winder, multi-roller surface winder; auxiliary equipment (trimming cutter and central cutting device, roll unwinding equipment and weighing unit, automatic roller puller), etc.