“Large Flow” Water Heaters - STM-WF

Categories : Control Equipment

STM-WF series "Large Flow" water heaters are used to heat up the mould and maintain temperature, although they can be used in other similar applications. High temperature water from the mould is returned to the cooling tank and cooled by direct cooling. It is then pressurized by the high-pressure pump, sent to the heating tank and finally to the mould with a constant temperature. The HANYOUNG temperature controller can maintain an accuracy of ±0.5℃.

Chiller

Categories : Cooling Equipment / Industrial Chillers

Extruder heading machine printing machine capping machine sealing machine accessories

Servo Robot For Insert-Pin Feeding

Categories : Industrial Robots

Auto insert-pin feeding can raise the production and reduce the manpower. It is easier to manage for auto insert-pin feeding equipment compared to manpower, and it’s much safer than manpower work. Product quality can be raised with auto insert-pin feeding equipment for high uniformity.

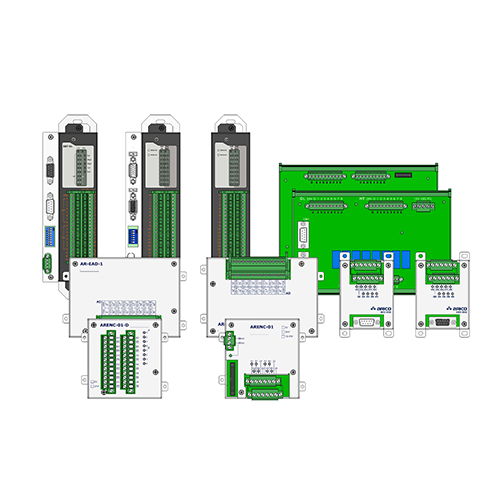

External Expansion Module - AR Series

Categories : Control Equipment

ARICO - The Best Solution Of AR Series - External Expansion Module ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. We was founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. We are not only good at producing customized precision AR Series - External Expansion module and related application equipment, but also provides high-quality AR Series - External Expansion module with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia and other countries. In addition to accumulating and stabilizing partners for related instruments with AR Series - External Expansion module, ARICO continues to conduct research and development in order to provide more stable and efficient machine stability, just for achieving a higher efficiency and stable instrument technology level on temperature control, displacement sensing, pressure sensing, injection molding machine IoT on rubber and plastic industry.

Single Screw Underwater Pelletizing Extrusion Line | CK-S

Categories : Single Screw Extruders

CYKF CK-S series Single Screw Underwater Pelletizing Extrusion Line can be applied to a wide range of applications. It is especially suitable for materials with high viscosity, low MI, and difficulty to be shaped, e.g., TPE and TPR. Possible materials : TPU, TPE, TPV, TPR, PP, PS, PLA, PVA, SEBS, EVA, Rubber, Hot-melt adhesive, Special resin, and Micro pellet, etc.

Multi-Cavity Hot Runner Temperature Controller - TC500

Categories : Hot Runner Systems

Wiring Friendly design Easy swapping for individual module failures Compact size, light weight, installed directly on the injection molding machine Automatic ID recognition Fast alternative for 230V / 380V power input Built-in NFB switch Arico

Mold Temperature Controller (YBMI/YBMD)

Categories : Control Equipment

Steady controlled temperature makes plastic molding accurate in size and consistent with quality. Accurate mold temperature solves the problem of plastic flow patterns, reducing flow and weld lines, gloss appearance, record grooves effect, silver streaking, stress-whitening, warping, and etc.... P.I.D temperature controllers are used for accurate control of temperature within±1℃. Two-step-heating selector makes rapid temperature increasing possible when require thus saving time and power specially start up in the morning. Patented “Heat-insulated” design improves your safety, extend the machine’s lifetime and make maintenance more efficiently. YBMI : By oil, suit for long-term continuous operation, keep the temperature steady, no flash on tiny and thin products, and no corrosion. However, the heater may be damaged if you do not use the thermo oil correctly or change oil routinely. Recommend to choose oil-type mold temperature controller when your required temperature is 150℃ or above. YBMD : By water, heating up faster, cooling better, harmless to your mold and more economic than oil type for maintenance and cost. However, the water boiling point is low and the element of different water may occur corrosion or limescale to affect the heat exchange and products quality. Recommend to choose water-type mold temperature controller when your required temperature is 150℃ or below.

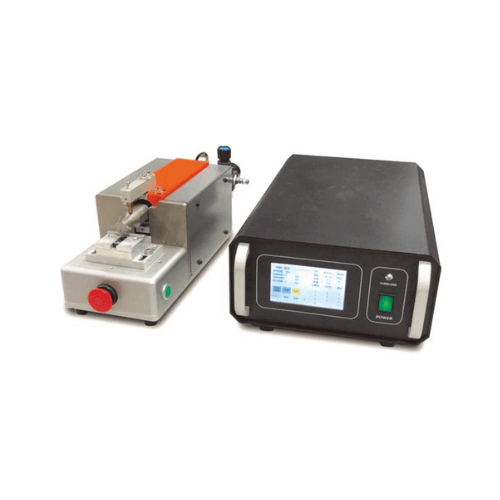

Ultrasonic Metal Welding Machine KWG0930-E

Categories : Automatic Welding Machine

Ultrasonic metal welding, generally for the fusion of low melting point metal materials such as copper, aluminum, etc. Taking the ultrasonic welding metal plate as an example, the two metal plates are overlapped and placed on the base, and the ultrasonic welding head is pressed against the coincident metal plate with appropriate pressure, and a lateral vibration of 20,000 to 40,000 times per second is applied. The two metal plate joints are subjected to high frequency vibration friction and welded. In this welding mode, the solvent is not required, and the welding portion does not need to pass current and heat, and is close to the cold joint, and the intermetallic compound is less likely to occur, and the structure changes little. The welding feature is that the deformation of the joint is less, the material is not melted, and the thermal influence of the material is not significantly changed. The fragile cast structure or the intermetallic compound can be obtained, and the fusion of the foil and the small joint can be achieved without strong resistance welding. Long foil can be applied by roller type continuous welding. KWG0935 model can be applied to lithium battery copper aluminum foil and aluminum nickel sheet welding, copper aluminum foil spot welding, capacitor copper aluminum foil spot welding, etc. KWG2020 model can be applied to lithium battery aluminum shell and aluminum nickel sheet welding, wire and terminal welding, wire butt welding, wire and metal plate welding, metal plate spot welding, etc........

Insert Injection Molding

Insert Injection Molding Technology is a manufacturing process that integrates pre-placed components, such as metal inserts, electronic parts, or other materials, into a plastic injection mold. During molding, molten plastic encapsulates the insert, creating a single, durable, and high-precision component. This technology enhances product strength, reduces assembly costs, and improves reliability, making it widely used in automotive, electronics, medical devices, and consumer products. By ensuring strong adhesion between plastic and inserted components, insert injection molding enables lightweight designs, enhanced durability, and improved performance in various applications. Key Advantages: Seamless integration of metal and plastic components Higher product strength and durability Cost-efficient by reducing assembly steps Customizable for complex geometries Enhanced precision and consistency Common Applications: Automotive Parts – Armrest trim panels, dashboard components, connectors Electronic Components – Connectors, circuit boards, protective casings Medical Devices – Surgical tools, sensor housings, implantable components Consumer Goods – Power tool grips, ergonomic handles, durable casings

Automation Equipment - Vertical Transporter

Categories : Industrial Robots

The mechanical arm signals are connected to accurately catch the finished product and protect the finished product. After tilting, the angle is automatically tilted to slide the finished product toward the workbench. RRP plastic countertop, does not scratch the finished product, beautiful appearance and wear resistance.

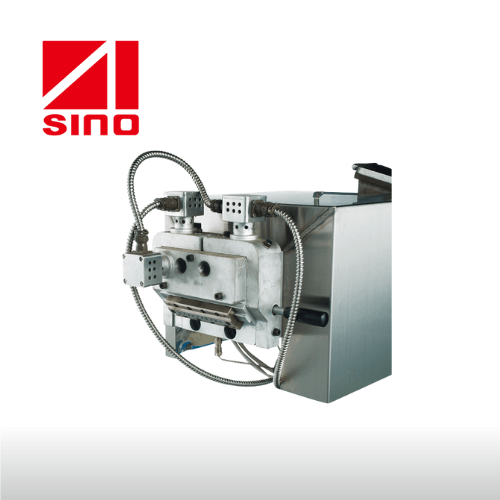

Strand Die-PSZ

Categories : Extrusion Dies / Dies Heads

The PSZ series strand die was developed by Sino-Alloy Machinery as an important accessory to their extruder line and essential for strand pelletizing. In order to improve the flow smoothness, Sino-Alloy has brought in special 3D simulation software to help design the die. Precision machining of the parts and the careful selection of materials is part of the process of making the most appropriate strand die. The PSZ series strand die has optimized flow design and temperature balance to achieve ease of cleaning, durability, and a smooth flow of material. Furthermore, Sino-Alloy can also help to design or improve strand dies from other manufacturers.

4 Shaft Auto Cutter

Categories : Cutting Machines

Application:To cut the variety of tape rolls, e.g.: double-sided tape, masking tape, Electrical Tape, construction tape, other kinds of tapes. yicheen