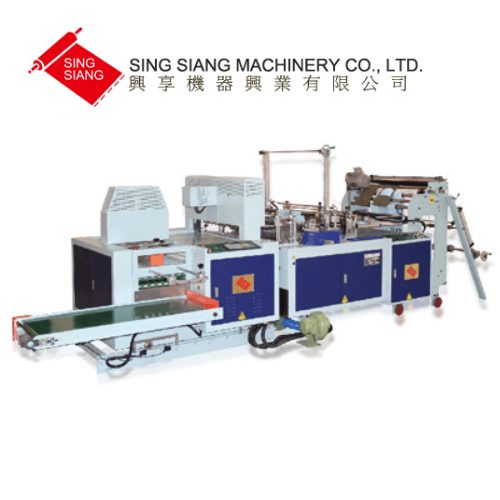

3-Folded T-shirt Style Garbage Bag Making Machine & Folding Machine

Categories : Plastic Bag Making Machines

1. Main convert servo motor controls, Germany SICK electric photo sensor tracking, make sure the feeding accurate and smooth. 2. Bag Cutting and Punching bags' vest simultaneously and neatly. There is no extra incisions between the bottom seal and the bottom line of the bag. 3. Adjust the count setting depends on the need, the machine can fold more than one bag once. 4. Fold's time is adjustable according to the bag making requirement, machine can automatically accomplish 2-time fold, 3-time fold, 4-time fold or 5-time fold. 5. The first and second fold of bag controlled by the servo control, the timing and speed are more accurately controlled. There is no more appears bag drop due to the wrong bag grabbing timing.

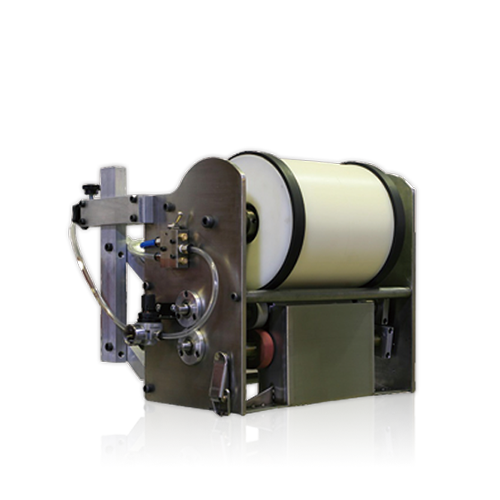

Plasma - JR

Categories : Surface Treatment Equipment

Applied to 30mm width or tube inside surface treatment. Detail specification contact please. Plasma treaters produce plasma surface treating to promote the adhesion of inks, adhesives, coatings, sealants & paints. Manufacturers integrate in-line plasma treatment equipment to enhance adhesion on plastics, composites, metals & glass surfaces. The plasma pretreatment process cleans, etches, & functionalizes surfaces to activate bonding sites by increasing wettability & surface energy.

Plastic Machine Controllers - AR Series

Categories : Industrial Software

The integrated innovative wise technology with reliable Distributed Control System contains higher performance. Software combined with State-of-art window screen to provide smart and instinct object-oriented editing style hybrid switching with simple and popular PLC ladder program editor. His high-speed Ethernet communication network link-up between Humanity Interface and remote devices to displaying the future one-stop control advantages! It can be broadly applied to automated machinery control, such as injection molding extruder machine controllers and equipment. Arico

Electronic Vacuum Regulator (0~ -101kpa)

Categories : Indicators and Sensors

Product Serial: KaoLu's QKL-B3V electronic vacuum regulator is a type of inline vacuum regulator (Operating schematic diagram below). One port is connected to a vacuum source, and the other port is connected to a chamber. The precision vacuum regulator works electronically to regulate the highest level of uniform vacuum pressure despite various input conditions. The vacuum level is directly linearly proportional to the electronic command signal to the vacuum pressure controller. When 0-10V corresponds to 0 to (–)14 psig, a 5VDc command signal to the digital vacuum regulator will create a (-)7 psig vacuum pressure. The flow rate of QKL-B3V electronic vacuum regulator valve is 640 L/min. Should a higher flow rate is required, it is possible to couple a volume booster to the negative pressure regulator. QKL-B3V digital vacuum regulator allows user to regulate vacuum level via analog or digital control signal. The regulator is not self-relief, meaning that it does not exhaust excess air to reach target vacuum level. The monitor output is available either as analog output or switch output. QKL-B3V operates in dual solenoid valve principle with a closed loop electronic control. The internal negative pressure transducer monitors the vacuum level and controls the operation of the inlet and the outlet solenoid valve of the vacuum pressure regulator valve. With this special design, QKL-B3V electronic vacuum control regulator can be installed inline in any orientation, offering high flow rate, high accuracy, and high repeatability. Our vacuum pressure controller has the advantage of digital communication, which allows users to calibrate and monitor regulator status remotely. As for ingress protection, QKL-B3V digital vacuum regulator is compliant to IP65, and the M12 cable connection allows user to easily install and dismount from inline operation. QKL-B3V electronic vacuum regulator has been used in applications such as thermoforming, leak testing, tube extrusion, and tank blanketing. In order to control the both inlet and outlet pressure that allows massive air pressure into and out of the system, the user can utilize the vacuum flow regulator. Please consult our factory for further information. KaoLu also offers other types of vacuum regulator to control vacuum level in a chamber. Please refer to our FC series vacuum breaker applications. https://www.genndih.com/proportional-flow-control-valve.htm

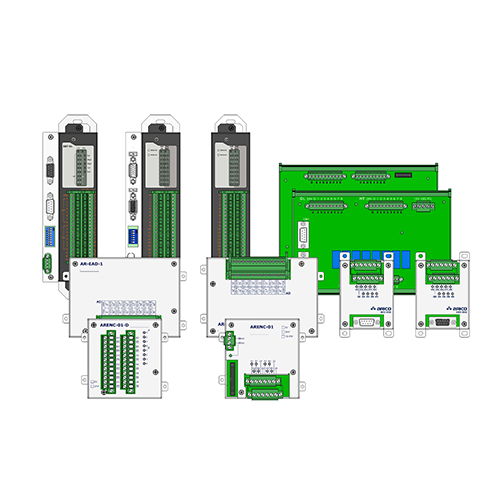

External Expansion Module - AR Series

Categories : Control Equipment

ARICO - The Best Solution Of AR Series - External Expansion Module ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. We was founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. We are not only good at producing customized precision AR Series - External Expansion module and related application equipment, but also provides high-quality AR Series - External Expansion module with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia and other countries. In addition to accumulating and stabilizing partners for related instruments with AR Series - External Expansion module, ARICO continues to conduct research and development in order to provide more stable and efficient machine stability, just for achieving a higher efficiency and stable instrument technology level on temperature control, displacement sensing, pressure sensing, injection molding machine IoT on rubber and plastic industry.

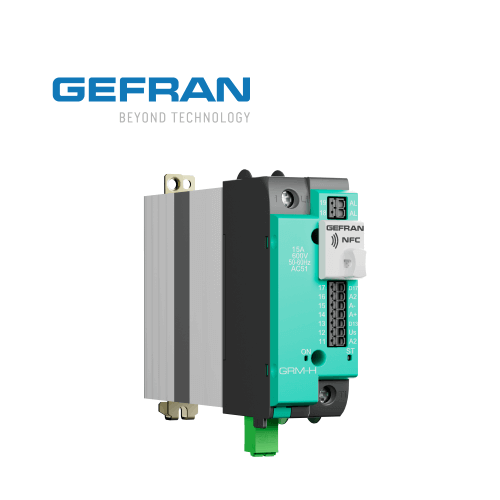

GRM-H Compact single phase Power Controller up to 120A

Categories : Control Equipment

The features of GRM-H Series Power Controllers ensure efficient heating management even in the case of complex electrical loads, which require special features, as in the case of infrared lamps or Silicon Carbide heating elements. Compact size from 15A to 120A Load voltage 480V, 600Vac Digital IO-Link communication Configurable control mode Zero Crossing, Burst Firing, Half Single Cycle or Phase Angle Feedback V,I,V2, I2, P, Z Soft start and current limits Logic command Vdc, Analog, PWM or IO-Link Advanced partial load break diagnostics (1/8) Slave control output (Two-phase/Three-phase) Configuration and Diagnostics via smartphone App with NFC technology Calibration and alarm reset commands via Digital Input Overview The ability to propose customized control solutions allows to rapidly satisfy the most different automation needs. For this purpose, the GRP series provides a wide range of extremely compact SSRs, with a solid basic structure but scalable as current sizes (from 15A to 120A), control type and configuration features. Control An accurate process control is the condition to achieve a constant and a high-quality production. To reach this goal it is necessary to manage in the best way the different types of industrial heaters from linear resistances to infrared lamps. For this purpose, the new series of SSR provides a series of control functionalities (ZC/ /BF/HSC/PA/Softstart) fully configurable to adapt to the various needs. Diagnostics Preventing possible anomalies allows to limit or eliminate harmful downtime and production. The GRP series includes dedicated functions such as the HB alarm for partial load breakage with accuracy of 1/8 of the total load, SCR short circuit, overtemperature and power failure. IO-Link communication Factory digitization is reaching its final frontier, the field level of the automation pyramid. In this level IO-Link is confirming itself as the most suitable communication to easily reach devices such as sensors and actuators. From this perspective, the GRP series has been developed to be integrated within this automation architecture. NFC configuration Simple and safe commissioning, maintenance and quick diagnostics are now within the capabilities of devices like SSR. All this thanks to the NFC technology, which allows to extend the user interface using normal Smartphone or Tablet as intelligent configurators. Thanks to an intuitive graphical user interface, setup or diagnostics are particularly easy.

Shrink Sleeve Width Measuring -Sleeve Eye

Categories : Shrink Sleeve Machinery

Sleeve Eye inspection system is designed exclusively for in line inspection of shrinkable label. It is capable of detecting lay flat width with ultrasonic system right after seaming process. Sleeve Eye inspection system is very versatile and it can also be installed on other machinery such as seaming machine and rewinding machine. Operators can now perform width inspection without the use of ruler. Simply enter the upper and lower limits of the width specifications, the system will alarm once out of limits situation occurs. Consequently, the operator can take appropriate remedial actions to improve product performance.

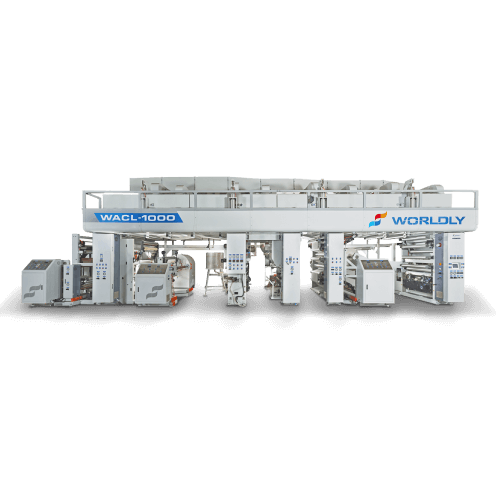

Aluminum Foil Coating & Laminating Machine (WACL Series)

Categories : Extrusion Coating Machines

WACL series is not just a convention dry laminating machine. The cold form foil is very much concerned proper & precise tension control to handle such thick laminates. In terms of tension control, this machine has mainly designed for Alu-alu foil multi-layers lamination. The arch dryer roller has synchronized with line speed, it’s very low friction and steady when film pass through the dryer. The internal drying chamber has safety LEL detection, this system can automatically discharge when detected high VOC occur during the production. This machine also combined heat seal lacquering coating function. Additional primer coating unit before lacquering unit, so it allows to apply two side (primer+heat seal) coating in one pass. The coating unit has alternative function with direct gravure and semi-flexo coating systems. Coating trolley along with self-pump system and able for quick job change.

Twin Body Die-Moving & Ejection Compression Molding Machine - FBS SERIES

Categories : Compression Molding Machines

APPLICATIONS: Conductive rubber, oil seal, automobile parts, keyboard pad, brake lining, mahjong, nontoxic rubber, thermos bottle plugs, nipple, medical rubber plugs etc.

Multi-Cavity Hot Runner Temperature Controller - TC500

Categories : Hot Runner Systems

Wiring Friendly design Easy swapping for individual module failures Compact size, light weight, installed directly on the injection molding machine Automatic ID recognition Fast alternative for 230V / 380V power input Built-in NFB switch Arico

Mini Flexo Pringing Machine LW-LF100-F (Plate Cylinders Fix)

Categories : Flexographic Printing Machines

Portable flexographic printing machine, suitable for printing the marks, logo, literature, and various kinds of one color printing purpose. Passive type machine install on the extruder, bag making machine and any kinds of conveying type equipment, thru the films flow to drive the printing head no power supply required economic and easy operation.

LT_Rectilinear Displacement Transducer

Categories : Indicators and Sensors

Reliability in measurement and control applications, even under harsh conditions. Brackets allow installation in most appropriate position. (Injection presses, hydraulic presses, sanders)