BoReTech: How to Make Recycling Waste PET Bottles Easier and Produce High-Quality rPET?

The global brands announced they would give up using virgin plastics in their products, which means more recycled plastics and rPET is required in markets. More than 60 brands and retailers have set corresponding reduction targets on the use of virgin plastic. The new commitment proposes that by 2025, the absolute benefit of virgin plastic will be reduced by nearly 20% compared with 2018.

In response to the use of recycled PET by global brand giants, they also tend to have higher quality requirements for its quality.

Control of the recycling process is the key to the quality of recycled PET products; BORETECH tells you how to do it!

BoReTech has been in the PET bottle recycling industry for more than 30 years. It has rich practical experience in the downstream quality requirements of recycled PET and how to control the quality of recycled PET.

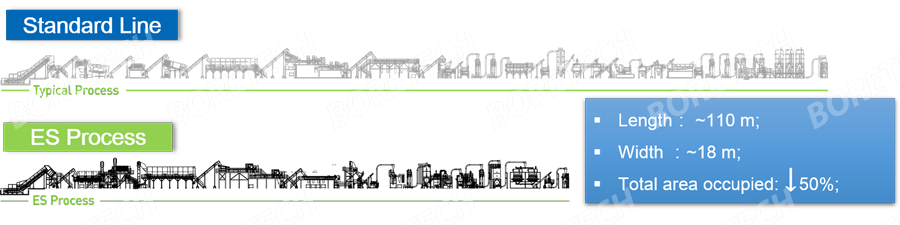

The latest ES process PET bottle recycling process uses an integrated equipment configuration to reduce area occupation, improve equipment automation, reduce equipment production unit energy consumption, keep operational safety, strengthen equipment operation stability, extend equipment durability, and improve the quality and stability of the final product——rPET flakes.

Herein you can find some successful cases of PET bottle recycling systems by BoReTech

High-grade application for food contact bottle-to-bottle

High-Quality rPET Flakes ——The flake quality is more reliable than the typical process. The flakes can be directly used in the production of bottle-to-bottle and Micro-denier filament. The physical and chemical properties of recycled PET pellets are close to virgin pellets;

Impurities content control like PVC, gules, labels, and moisture content are the core index for the quality of rPET flakes. The main modular of ES process PET bottle recycling lines can totally solve these problems.

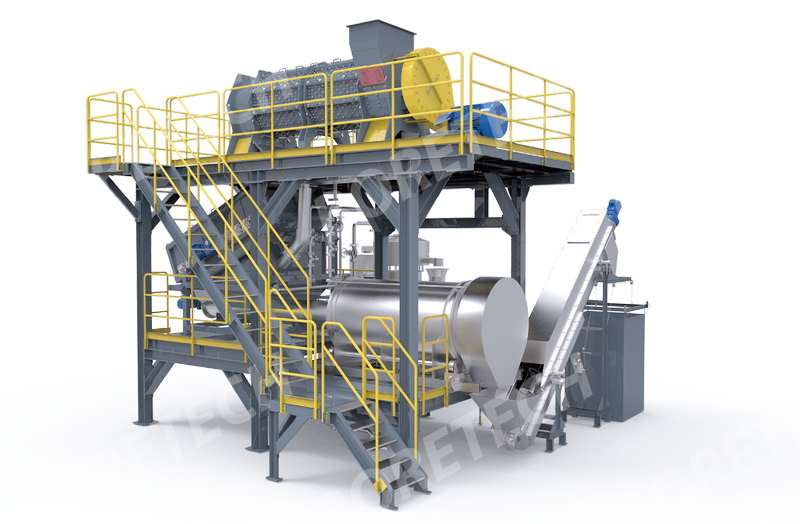

LABEL REMOVAL AND FLUSHING MODULE

label removal and pre-washing functions in one machine.

The water circulation system can simultaneously remove the label and clean its surface.

Heat-shrinkage label scrapping rate is more than 95%.

The in-line process of water filtration and circulation system achieves the most efficient water reuse.

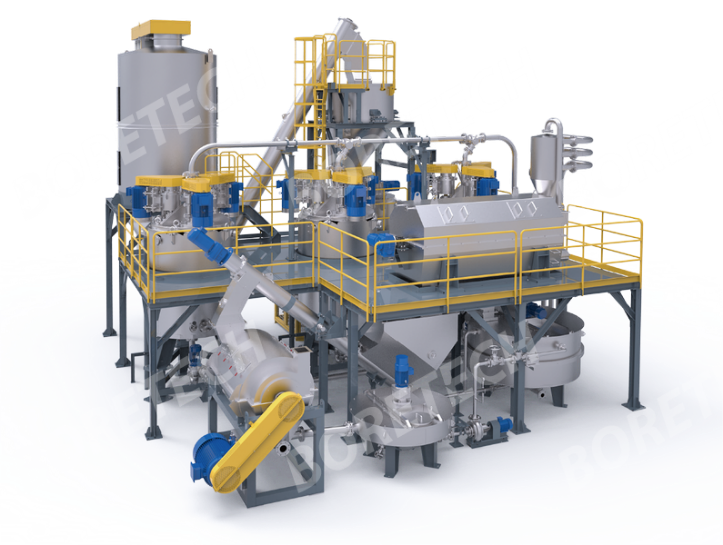

INTENSIVE HOT WASHING MODULE

The process flow is rationalized, compacted, simplified, and occupies less area.

Soaking and powerful washing functions in one machine.

Modular design, prefab pipeline, standardization of parts, and precise connection save the installation time.

The precision filtration system avoids separated contaminants in chemical water polluting rPET flakes.

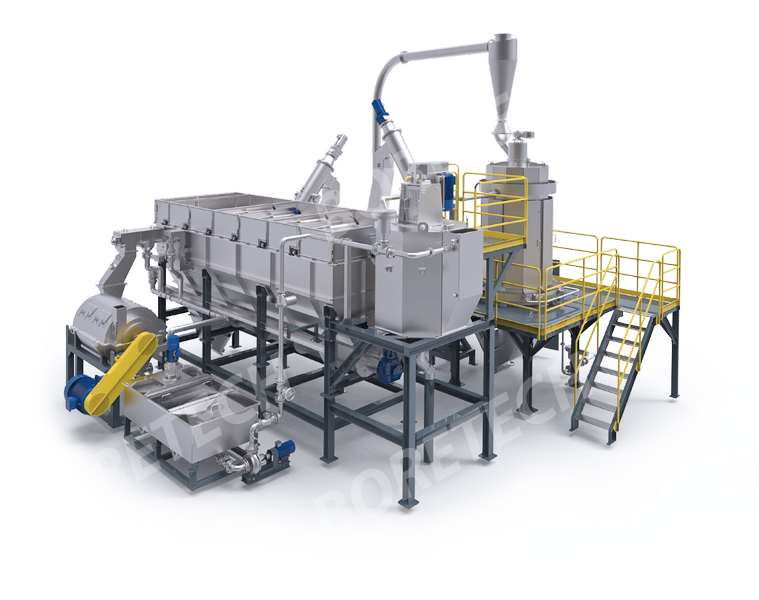

ENHANCED RINSING MODULE

Modular design enables processes and equipment into multi-functional modular.

The cavitation of ultrasonic waves is used to impact and peel off the dirt on the surface of flakes to achieve high-performance cleaning.

The flotation module can remove Polyolefin material with minimized PET loss.

The in-line rinsing water filtration system ensures rinsing efficiency.

For more high-quality rPET flakes and PET bottle recycling processes, visit www.bo-re-tech.com

or write a mail to us, now! [email protected]

Extruders and Extrusion Lines

- Air Bubble Film Extrusion Line

- Air Bubble Film Extrusion Line

- Air Bubble Sheet Co-extrusion Line

- Bag Making Machines

- Blow Film Making Machine

- Blown Film Extruders

- Blown Film Making Machine

- Cast Film Machine

- Coating Machine

- EPS/EPE Foam Sheet Extrusion Lines

- Extruder

- Extrusion Laminating Machines

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Monofilament Extruding Machinery

- Monofilament Extrusion Line

- PET Strapping Band Extrusion Lines

- Plastic Bag Making Machines

- Plastic Film Co-Extrusion

- Plastic Pipe Making Machines

- Plastic Tube Making Machine

- PVC Hose Making Machine

- Straw Making Machines

- Twin Screw Extruder

- Twin Screw Extruders

- Woven Bag Making Machine

Plastic Recycling Machinery

- Bottle Washing Line

- Crusher

- Granulators

- Pelletizer

- Pelletizers

- Pelletizing Machines

- PET Bottle Recycling Line

- PET Hot Washing Line

- Plastic Pelletizing Machines

- Plastic Recycling Equipment for Preprocessing

- Plastic Recycling Machines

- Plastic Waste Recycling Machine

- Recycling Lines

- Recycling Machine

- Shredders

- Squeezers

- Washing Lines

- Waste Recycling Equipment