MING JILEE: Turnkey for Air Bubble / EPE Foam Converting Production

MING JILEE provides all kinds of converting machines for air bubble and EPE foam material.

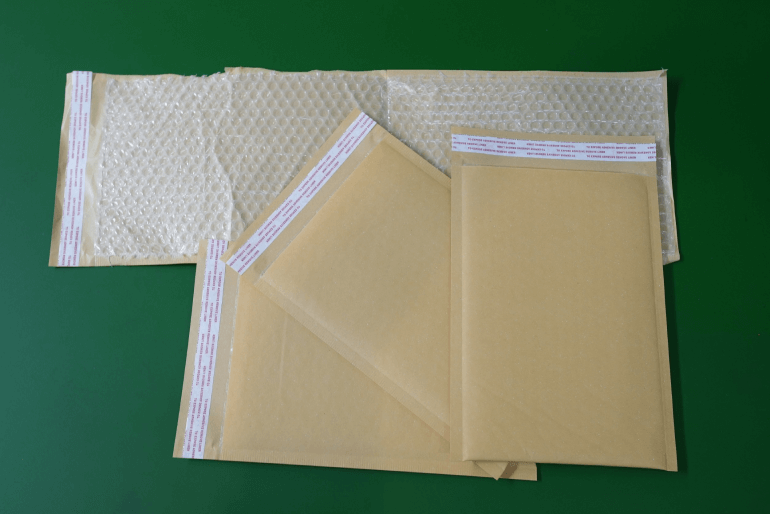

For the different applications, we can cut the material into envelope, bag, sheet, hole punching, coreless roll.

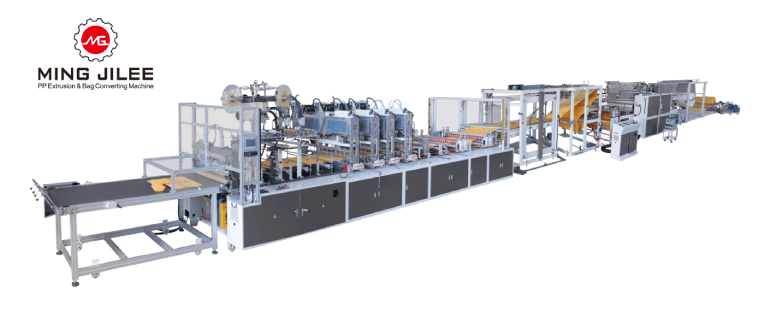

The latest model MGA-47E-900LAMF is full servo motor control, including the size, heat sealing and cooling station. In-line laminating station allows factory to prepare separate material to convert into the envelopes.

General Machine Specifications

(1) Machine Dimension : 26,000 (L) × 2,450 (W) × 2,200 (H) mm

(2) Complete Machine Weight : 15,400 kg

(3) Required Container : 3 sets of 40HQ

(4) Machine Installed Power : 125 A

(5) Required Power : 22 kw in 480V and 48kw in 220V, 3 phase

Machine Features

(1) Air Bubble quick change:

Due to the short length of air bubble film, we design the quick change device to reach non-stop production for saving the waste because of the changing material.

(2) Best Lamination quality:

Kraft Paper / PE Poly Bubble Mailer Making Machine is installed by European brand lamination system to do in-line lamination for Kraft paper with air bubble film or LDPE with air bubble film. With special design, we won't break the air bubble after laminating processing.

(3) Strongest edge Sealing Seam:

The transversal sealing seam of Kraft Paper / PE Poly Bubble Mailer Making Machine is controlled by motor, with mechanical driven system, it makes sure the operators to get the higher pressure and best sealing quality.

(4) In-line hot melt glue system:

MING JILEE only chooses the global and premium suppliers to install the hot melt system on MING JILEE Kraft Paper / PE Poly Bubble Mailer Making Machine. It gets perfect glue control to reach intermittence glue or continuous glue function.

(5) Synchronizing length control:

Kraft Paper / PE Poly Bubble Mailer Making Machine is equipped many servo motors to synchronize the length supply. With special belt system, we can feed the precise length to cut the exact setting size without any slippery of material.

(6) Multi-function auto conveyor:

With serveral quantity settings, to get special stacking as operators' favorite way. It helps operators to take already counter mailer for last packing purpose.

For Further information about In-Line Lamination PE Poly & Kraft Paper Bubble Mailer Machine, please click here or watch video below.

Extruders and Extrusion Lines

- Air Bubble Film Extrusion Line

- Air Bubble Film Extrusion Line

- Air Bubble Sheet Co-extrusion Line

- Bag Making Machines

- Blow Film Making Machine

- Blown Film Extruders

- Blown Film Making Machine

- Cast Film Machine

- Coating Machine

- EPS/EPE Foam Sheet Extrusion Lines

- Extruder

- Extrusion Laminating Machines

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Monofilament Extruding Machinery

- Monofilament Extrusion Line

- PET Strapping Band Extrusion Lines

- Plastic Bag Making Machines

- Plastic Film Co-Extrusion

- Plastic Pipe Making Machines

- Plastic Tube Making Machine

- PVC Hose Making Machine

- Straw Making Machines

- Twin Screw Extruder

- Twin Screw Extruders

- Woven Bag Making Machine

Plastic Recycling Machinery

- Bottle Washing Line

- Crusher

- Granulators

- Pelletizer

- Pelletizers

- Pelletizing Machines

- PET Bottle Recycling Line

- PET Hot Washing Line

- Plastic Pelletizing Machines

- Plastic Recycling Equipment for Preprocessing

- Plastic Recycling Machines

- Plastic Waste Recycling Machine

- Recycling Lines

- Recycling Machine

- Shredders

- Squeezers

- Washing Lines

- Waste Recycling Equipment