MING JILEE: High Expertise in Solutions for all Kinds of Bag Making Machines

MING JILEE focuses on Bag converting machine / Stationery Folder machine / Air bubble envelope machine / Extrusion line / All kinds of masks machines since 1987. For the different applications, Ming Jilee provides the solutions to worldwide global brands. Our main customers are from the USA, Whole Europe and Asia.

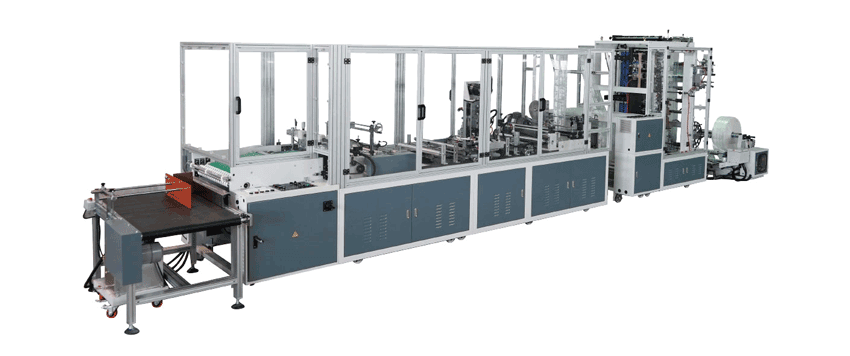

MING JILEE will bring the latest in-line zipper bag side sealing machine (MGA-06Z-800D) to 2022 K Show in Dusseldorf Germany. In order to reach 220 cycle/min production, MING JILEE installs total 3 servo motors to control the good tension and keep high-speed smooth production.

MACHINE PERFORMANCE:

(1) Feed material : LDPE, HDPE, PP, EVA

(2) Single layer film thickness

- Side sealing bag : 0.02 - 0.08 mm

- Zipper bag : 0.04 - 0.08 mm

(3) Effective bag width (feeding length) : 85 - 600 mm

(4) Effective bag length (sealing width) : 150 - 650 mm

(5) Output : 40 - 220 pcs /min (depend on size and thickness)

FEATURES:

(1) Taiwan made PLC controller. High stable, best quality and internet connection.

(2) The size control of Zipper Bag Side Sealing Machine is by servo motor. Made in Japan.

(3) Zipper Bag Side Sealing Machine is equipped mark sensor for printed material.

(4) For getting the best quality of zipper bag product, unwinding station is mount the auto tension control.

(5) The individual zipper strip unwinder with motor control to get the high quality of zipper sealing quality.

(6) Ultrasonic welding is design by motor driven for highest speed production.

(7) The ultrasonic welding station to crack the zipper on the edge of the bag for easy side sealing cutting.

(8) the best design of zipper bag side sealing machine, made in Taiwan.

For Further information about High-Speed Zipper Strip Hot Lamination Side Sealing Machine

Extruders and Extrusion Lines

- Air Bubble Film Extrusion Line

- Air Bubble Film Extrusion Line

- Air Bubble Sheet Co-extrusion Line

- Bag Making Machines

- Blow Film Making Machine

- Blown Film Extruders

- Blown Film Making Machine

- Cast Film Machine

- Coating Machine

- EPS/EPE Foam Sheet Extrusion Lines

- Extruder

- Extrusion Laminating Machines

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Monofilament Extruding Machinery

- Monofilament Extrusion Line

- PET Strapping Band Extrusion Lines

- Plastic Bag Making Machines

- Plastic Film Co-Extrusion

- Plastic Pipe Making Machines

- Plastic Tube Making Machine

- PVC Hose Making Machine

- Straw Making Machines

- Twin Screw Extruder

- Twin Screw Extruders

- Woven Bag Making Machine

Plastic Recycling Machinery

- Bottle Washing Line

- Crusher

- Granulators

- Pelletizer

- Pelletizers

- Pelletizing Machines

- PET Bottle Recycling Line

- PET Hot Washing Line

- Plastic Pelletizing Machines

- Plastic Recycling Equipment for Preprocessing

- Plastic Recycling Machines

- Plastic Waste Recycling Machine

- Recycling Lines

- Recycling Machine

- Shredders

- Squeezers

- Washing Lines

- Waste Recycling Equipment