PARTICO - Achieving Lucrative Joint Harvest During COVID-19

Overcoming difficulties with technology

Due to the pandemic many machinery manufacturers have been shaken dramatically in terms of production, communication, logistics and after sales service. When we create solutions that give positive outcomes, Partico is the one to be thought about. For over 25 years they have been in business with vast experience in manufacturing and applying thermoplastic recycling machines.

Through this, Partico is well known for making remarkable performance and high quality machines by utilizing core components, key technology and user-friendly innovations.

Through social media they have acquired great outcomes by improving their communication with their clients and the creation of video content of their machines. In this way, Partico has been successfully offering immediate technical solutions and increasingly improving the visibility of their machines both in the domestic and international market.

Partico works & expertise

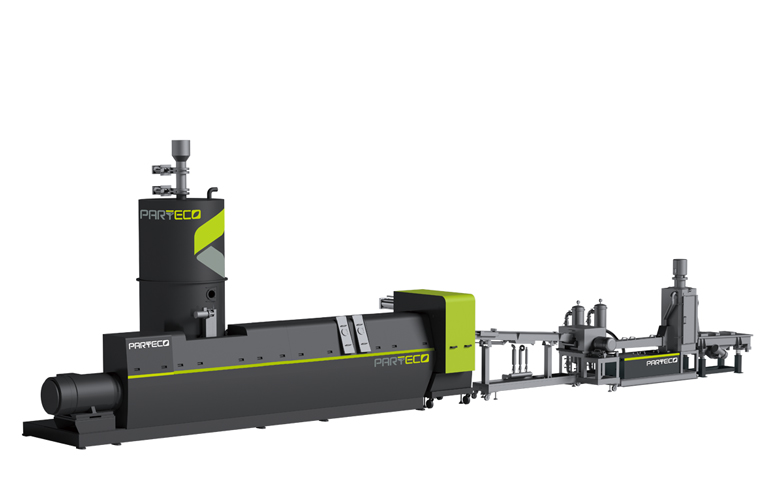

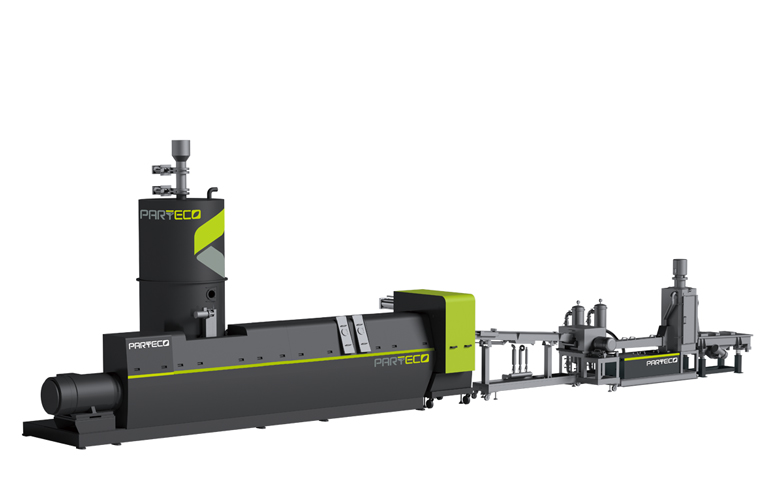

Partico specializes in the pelletizer of plastic materials recycling machines. Two of the biggest best seller machines are the HF-FTO- Vacuum Series for PET plastics and the HF-FTO 3 in 1 extruder pelletizer.

The Vacuum Series machine is based on four steps. The first stage happens on the vacuum drying system with the removal of liquids and impurities, then passes through the melting extrusion, filtering and then granulating.

The 3-in-1 Extruder Pelletizer machine is based on the application of shred, extrude and pelletize the fluffy recycled plastic, which customized recycled processing solution is highly demanded for its clientele. This machine is suitable to handle different types of materials, such as: PE, LDPE, LLDPE, HDPE, PP, PET, PS, PA, BOPP, ABS.

Partico consists of a series of granulating systems, such as: Underwater, Water Ring and Flow Channel. Flow Channel advantages are the automation and continuous production process, reduction of manpower and improved efficiency effect. The Underwater and Water Ring process is very similar to each other.The difference in the Underwater is that the pellets are cutted in water, while the Water Ring enters the water once the pellets are cutted.

Partico Uniqueness

Something that makes Partico different from other suppliers of the recycling industry, is the wide knowledge of different plastic raw material characteristics. In this way, it allows them to provide the most suitable machine and the best suggestion according to the needs of the client. If the customer needs more than a pelletizer machine, Partico can also coordinate and prepare a complete set of recycling equipment.

For more details, see the links below for more information

Official Website:

https://www.partico.com.tw

Partico in PRM-TAIWAN:

https://www.prm-taiwan.com/com/Partico_Machinery_Inc.html

Due to the pandemic many machinery manufacturers have been shaken dramatically in terms of production, communication, logistics and after sales service. When we create solutions that give positive outcomes, Partico is the one to be thought about. For over 25 years they have been in business with vast experience in manufacturing and applying thermoplastic recycling machines.

Through this, Partico is well known for making remarkable performance and high quality machines by utilizing core components, key technology and user-friendly innovations.

Through social media they have acquired great outcomes by improving their communication with their clients and the creation of video content of their machines. In this way, Partico has been successfully offering immediate technical solutions and increasingly improving the visibility of their machines both in the domestic and international market.

Partico works & expertise

Partico specializes in the pelletizer of plastic materials recycling machines. Two of the biggest best seller machines are the HF-FTO- Vacuum Series for PET plastics and the HF-FTO 3 in 1 extruder pelletizer.

The Vacuum Series machine is based on four steps. The first stage happens on the vacuum drying system with the removal of liquids and impurities, then passes through the melting extrusion, filtering and then granulating.

The 3-in-1 Extruder Pelletizer machine is based on the application of shred, extrude and pelletize the fluffy recycled plastic, which customized recycled processing solution is highly demanded for its clientele. This machine is suitable to handle different types of materials, such as: PE, LDPE, LLDPE, HDPE, PP, PET, PS, PA, BOPP, ABS.

Partico consists of a series of granulating systems, such as: Underwater, Water Ring and Flow Channel. Flow Channel advantages are the automation and continuous production process, reduction of manpower and improved efficiency effect. The Underwater and Water Ring process is very similar to each other.The difference in the Underwater is that the pellets are cutted in water, while the Water Ring enters the water once the pellets are cutted.

Partico Uniqueness

Something that makes Partico different from other suppliers of the recycling industry, is the wide knowledge of different plastic raw material characteristics. In this way, it allows them to provide the most suitable machine and the best suggestion according to the needs of the client. If the customer needs more than a pelletizer machine, Partico can also coordinate and prepare a complete set of recycling equipment.

For more details, see the links below for more information

Official Website:

https://www.partico.com.tw

Partico in PRM-TAIWAN:

https://www.prm-taiwan.com/com/Partico_Machinery_Inc.html

E-News Categories

Extruders and Extrusion Lines

- Air Bubble Film Extrusion Line

- Air Bubble Film Extrusion Line

- Air Bubble Sheet Co-extrusion Line

- Bag Making Machines

- Blow Film Making Machine

- Blown Film Extruders

- Blown Film Making Machine

- Cast Film Machine

- Coating Machine

- EPS/EPE Foam Sheet Extrusion Lines

- Extruder

- Extrusion Laminating Machines

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Monofilament Extruding Machinery

- Monofilament Extrusion Line

- PET Strapping Band Extrusion Lines

- Plastic Bag Making Machines

- Plastic Film Co-Extrusion

- Plastic Pipe Making Machines

- Plastic Tube Making Machine

- PVC Hose Making Machine

- Straw Making Machines

- Twin Screw Extruder

- Twin Screw Extruders

- Woven Bag Making Machine

Plastic Recycling Machinery

- Bottle Washing Line

- Crusher

- Granulators

- Pelletizer

- Pelletizers

- Pelletizing Machines

- PET Bottle Recycling Line

- PET Hot Washing Line

- Plastic Pelletizing Machines

- Plastic Recycling Equipment for Preprocessing

- Plastic Recycling Machines

- Plastic Waste Recycling Machine

- Recycling Lines

- Recycling Machine

- Shredders

- Squeezers

- Washing Lines

- Waste Recycling Equipment