JIN KUO HUA Have Developed In The Plastic & Rubber Compounding Fields For Over 60 Years - Here Is Our High Filler Modify Compound Making Lin

Jin Kuo Hua Plastic Machine Co., Ltd. was founded in 1956 and since then we have developed our expertise in the plastic & rubber compounding fields. Our current product line includes our Masterbatch Compound Manufacturing Line, High Filler (CaCo3, TiO2 or Talc) Modified Compound Making Line and we also operate in the wire and cable industries, with our machinery able to process Soft PVC and Halogen Free Materials (EVA, SEBS, PE base) into pellets.

Apart from our compounding lines, we also have multiple different extruders our range includes Profile Extruders, PVC Corrugated Sheet Extruder and PVC Flooring Sheet Manufacturing Line etc.

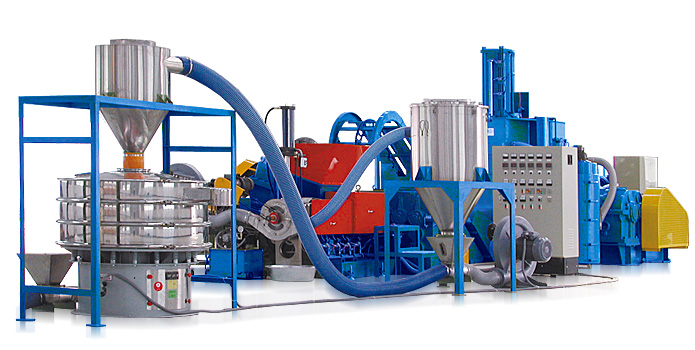

High Filler Modified Compound Making Line

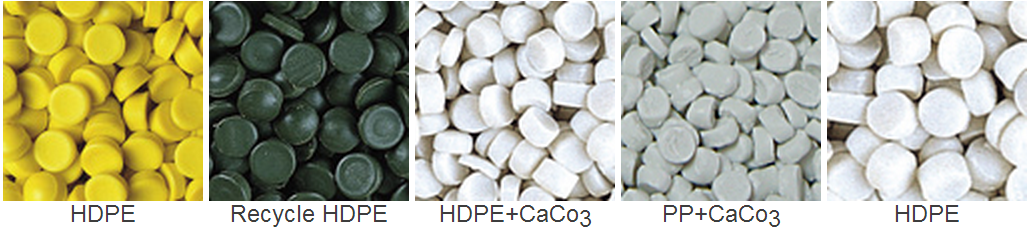

Our High Filler Modified Compound Making Line uses our extruder machinery to process different types of compound materials into pellets.

Our simple to operate line, comprises of a dispersion kneader and extruder to meet all of your specific compound making needs. (HDPE, Recycled HDPE, Ti02, Talc, PP+CaCo3 etc)

We have a strong technology background and have developed a rational management system to conduct strict inspections on all of the products at every stage of the manufacturing process to ensure that all of our products meet client’s expectations and our own high standards.

Our manufacturing lines are automated to keep up with the high demands of mass production. This reduces the energy and manpower needs saving you time and money. We are constantly striving to improve our R&D to keep up with the ever changing market demands. When going into business with JKH it isn’t just a simple business transaction. It’s a long-lasting partnership.1. Best dispersion result.

2. Products reach FDA standard of the quality.

3. Large output capacity to low the production process of cost.

Auxiliary Equipment

1. Temperature Controller: Good to accelerate the mixing materials of the Temperature.

2. Industry Air Conditioner: Good to conduct the Cooling Housing to cool the cutting pellets.

3. Water Chiller: Good for the Extruder and Cooling System. Using the Pure water to keep nice and clean circulation status and lower the water consumptions cost also avoid the lime scale to extend the machine life.

Modify Compound Pellets could be using in most of the products such as:

1. Blow Film Industry

2. Injection Molding Industry

3. Food Container

4. Water Tank

5. Agriculture films

6. Shopping Bags.

7. Woven Bags.

Future Exhibitions

In this year 2018, JIN KUO HUA has a plan of attending Chinaplas and Taipeiplas. Welcome to visit us!

Chinaplas2018

Date : April 24 - 27, 2018

Booth No. :3H B93

|

More Information in PRM:

Official Website: |

Extruders and Extrusion Lines

- Air Bubble Film Extrusion Line

- Air Bubble Film Extrusion Line

- Air Bubble Sheet Co-extrusion Line

- Bag Making Machines

- Blow Film Making Machine

- Blown Film Extruders

- Blown Film Making Machine

- Cast Film Machine

- Coating Machine

- EPS/EPE Foam Sheet Extrusion Lines

- Extruder

- Extrusion Laminating Machines

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Monofilament Extruding Machinery

- Monofilament Extrusion Line

- PET Strapping Band Extrusion Lines

- Plastic Bag Making Machines

- Plastic Film Co-Extrusion

- Plastic Pipe Making Machines

- Plastic Tube Making Machine

- PVC Hose Making Machine

- Straw Making Machines

- Twin Screw Extruder

- Twin Screw Extruders

- Woven Bag Making Machine

Plastic Recycling Machinery

- Bottle Washing Line

- Crusher

- Granulators

- Pelletizer

- Pelletizers

- Pelletizing Machines

- PET Bottle Recycling Line

- PET Hot Washing Line

- Plastic Pelletizing Machines

- Plastic Recycling Equipment for Preprocessing

- Plastic Recycling Machines

- Plastic Waste Recycling Machine

- Recycling Lines

- Recycling Machine

- Shredders

- Squeezers

- Washing Lines

- Waste Recycling Equipment