Plastic Recycling Machinery

HOT NEWS

5 Tips to Increase Efficiency in Plastic Recycling Process

In parallel with the increase in the consumption of plastics, driven by economic development and population growth, global plastic waste is projected to triple by 2060 based on OECD reports. Increasing plastic recycling efficiency is one of the major keys to returning more plastic waste to production lines as a valuable recycled polymer. Here we have listed 5 tips to increase efficiency in the plastic recycling process.

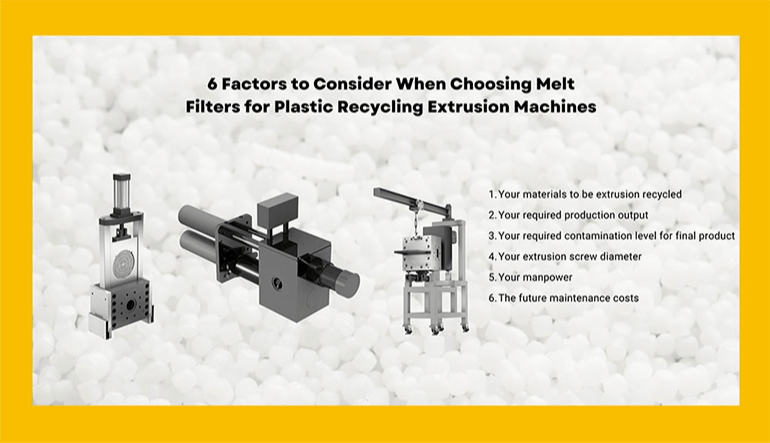

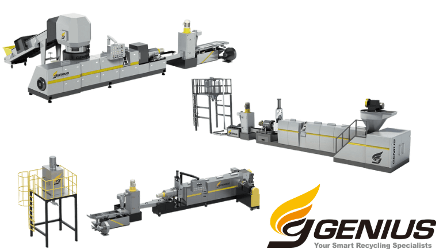

GENIUS: What to Consider When Choosing Melt Filters for Plastic Recycling Machines?

Melt Filter is an important component of Plastic Recycling Extrusion Machine. It helps to improve the end product's quality while also increasing production. However, as you are aware, not all melt filters for recycling and filtering post-consumer and post-industrial plastics are the same. They differ in terms of performance and price. If you want to buy an optimal melt filter for your plastic recycling extrusion machine, you should think about various variables before making your final decision. In this article, we will discuss 6 critical aspects that will assist you...

TwinScrew’s Bioplastic Solutions Enhance the Carbon Emission-lowering Efficiency

The plastics industry is undergoing critical transformation to achieve the goal of net zero defined in UNFCCC. It is generally accepted that increase in reuse, reduction and recycling are essential actions. However, the latest annual recycling rate is 9% and only 40% of the recycled plastic wastes went to the products though the European area leads the world in awareness of environmental sustainability and recycling infrastructures.

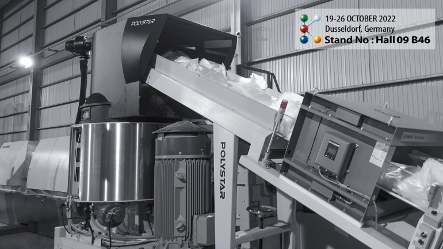

K Show 2022 -Recycling for Post-consumer and Post-industrial Plastics on the Rise

New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. The instability of raw material prices and supplies also forces plastic producers to better recycle their production waste.

Recycling for Post-consumer and Post-industrial Plastics on the Rise

It may be good for everyone to be in the plastic recycling business whether you are a recycler or a producer. New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. The instability of raw material prices and supplies also forces plastic producers to better recycle their production waste. With the great importance of recycled-based plastic products, the global demand for plastic recycling is expanding.

GENIUS: 5 Minutes to Understand Plastic Pelletizing Machine

Pelletizing plastics is the process that includes melting and cutting polymers into easy-to-handle plastic pellets. Understanding pelletizing system and feeding system will help you select the right plastic pelletizing machine! Pelletizers are the essential parts of plastic pelletizing machines. There are several types of pelletizing methods. Die face cutting system, also known as hot die cutting pelletizing system is the most popular used system among the other options.

GEORDING Shredder Integrated Recycling Machine: One Step Solution for Reduce, Reuse and Recycle

GEORDING introduces a single shaft shredder integrated recycling machine which is developed based on customer requirements as a one-step solution for processing various types of recycling materials. The integration and development of the machinery, brings the users with faster recycling process, lower labor cost and lower energy consumption, clear and high quality raw material outputs.

3 Crucial Factors for a Complete Circular Economy

The production of plastic bags and plastic films around the globe is huge. In recent years, producers have implemented new technologies to complete a circular economy in their factories. To make this possible, producers need a plastic recycling system that produces good quality pellets and a blown film machine that can process up to 100% recycled plastic pellets.