Molds and Dies

HOT NEWS

GMA at Chinaplas 2021, Reaching Customers During Pandemic Times

This year, 2021, has been open to speculations about what is going to be the economic performance and how different industries are responding to pandemic times. After 1 year without international exhibitions, Chinaplas was the first big exhibition of the industry, therefore all the main players were waiting for the results.

GMA to Showcase the Latest Trends in Extrusion Dies During Chinaplas 2021

When it comes to machinery and peripherals such as extrusion dies, one of the first things that come to manufacturers minds is how to solve a need. In other words, when you want to purchase something, you are looking for a solution for a problem or a need, GMA’s extrusion dies are well known for fitting different needs, thanks to their capacity of adaptability to produce a wide range of products that make them always be at the vanguard in the industry.

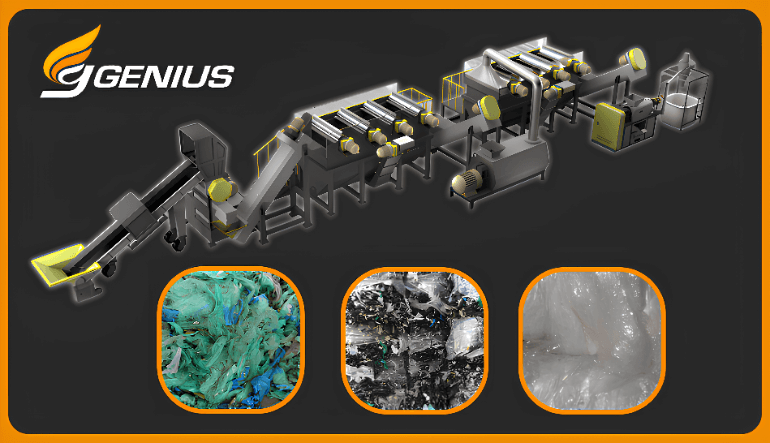

Supplying and Increasing Production of High Quality Extrusion Meltblown Dies During Pandemic

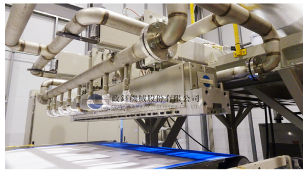

This year the use of meltblown and non-woven fabrics has suffered an exponential increase on its demand, this due COVID-19 pandemic. Taiwan has one key actor in the industry, GMA Machinery

GMA: Covid-19 Outbreaks to the Whole World, Medical Supplies Become Indispensable Poperies to Every Country, such like Protective Clothing, Gown, Goggles, Protective Mask, N95 Mask etc.

In past 3 months, GMA received a lot of MB die inquiries from many countries, not only die, including gear pump and filter which can be used on melt blown fabric production line. Melt blown fabric is mostly used for mask and protective clothing, or filter.

GMA: Customized Production for Extrusion Dies, Quality Makes us Different!

GMA, a professional extrusion die manufacturer with over 30-year experience in Taiwan, focus on design and making various extrusion dies for different application.

Improve quality, reduce waste of material and increase production with ANNTONG's Liquid Silicone Rubber (LSR) Injection Molding.

ANNTONG offers LSR (liquid silicone rubber) injection molding solutions. We provide LSR mold, LSR cold deck, valve gate system, uniform heating system, and total solution to help you molding“LSR”, “R+R”(LSR+LSR) , “P+R (plastic with LSR), “M+R” (metal with LSR)

Increase Effects Up to 50% in Mold Change, Great Investment in Productivity

If you want to know more about the Quick Mold Change Systems and send inquiry.

Keys of the Success for LSR Molding

“ Flow balance” and ” Thermal balance” is the key for successful LSR injection molding. Ann Tong industrial company is well known LSR cold deck provider with inexpensive price and match the above successful factors. Not only provide valve gate cold deck, but also provide 90% finished mold (User only need to make cavity core only). We also offer the thermal analysis to do DFM (Design for manufacturing) for reference.