Blow Film Making Machine

HOT NEWS

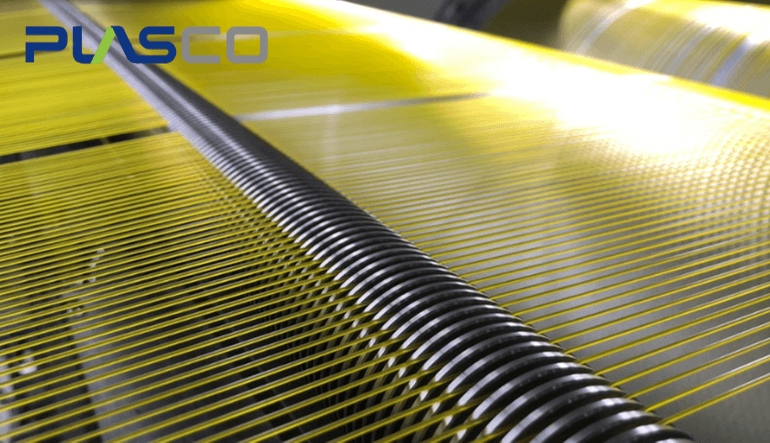

PLASCO: What Are The Trends for Monofilament Extrusion Line in 2023?

As a leading manufacturer in the monofilament yarn making machine industry, PLASCO would like to share the 4 main trends we expect to see in the development of monofilament yarn making machines in 2023.

JANDI’S: The Strength of JANDI’S with Successful Case Sharing

Mr. Samet Aydoğan is the Export Director of Aydoğan Plastik which is based in Turkey. Aydoğan has been in the flexible packaging sector since 1988. They are a tailor-made producer who is addressing almost all sectors, starting from food, personal & home cares to textile and many others. As a tailor-made producer, they have to make all the choices available for their clients, and that is why they chose JANDI’S, we make their requirements come true!

PE Bag Production – Which Extruder is the Best Choice?

For PE bag production, single layer blown film machine has been the most common type of extruder to use. It is probably still the best machine for products such as fruit and vegetable bags (perforated bag-on-roll) that use mainly virgin materials with low film thickness ranging from 6 to 18 microns. Single layer machine is also the favorable choice for biodegradable bag production.

POLYSTAR - PE Bag Producers Step up in Quality and Efficiency in Vietnam

The Vietnamese plastic sector has grown significantly in the past 5 years thanks to many unique advantages that the country has. The ability to produce lower cost yet good quality plastic products is ideal for export markets such as the US, Japan, Europe, Australia and Cambodia. The local market demand is also increasing in sectors such as live seafood packaging, industrial and agricultural film, in a country of large population of nearly 100 million.

HSIN LONG: Innovations for Optimal Solutions

HSIN LONG, one of the leading manufacturers of Blown Film Die Head Industry, has been forging its outstanding reputation for over 50 years. Hsin Long began as an OEM cooperating with Taiwanese companies who could supply different components to their customers.

ABA Blown Film Machine – What’s the advantage?

For PE bag production, single layer blown film machine has been the most common type of extruder to use. It is probably still the best machine for products such as fruit and vegetable bags (perforated bag-on-roll) that use mainly virgin materials with low film thickness ranging from 6 to 15 microns. Single layer machine is also the favorable choice for biodegradable bag production.

KUNG HSING: Innovating the Market with their 5 Layer Blown Film Co-Extrusion Line

Nowadays new changes in the Industry are a must for companies, especially if they want to stay at the vanguard in the industry. Kung Hsing is well known for their constant innovation, this time they have the 5 Layer Blown Film Extrusion Line which is the main trends to substitute the 3 layers.

JANDI’S - Biodegradable JIT Series

Green manufacturing and the high rate of pollution caused by the plastic film are the major concerns about the protection of the environment. JANDI’S has found a way to “Greenilize” their bag making machines resulting in a big win for the environment and the industry itself. Using Biodegradable material is one of the success solutions for the global issue.