Chi Chang Machinery Meeting the Highest Quality Standards for Almost Half of a Century

Nowadays one of the main concerns is finding reliable and experienced suppliers for different kinds of machines. Taiwanese companies are famous for its performance and service quality. One manufacturer that must be taken into consideration is CHI CHANG MACHINERY CO.,LTD (CCM), a company with almost half a century of experience in the industry, founded in 1972.

CCM is dedicated to the design and manufacture of plastic extrusion machinery. They have a wide range of products that have been developed with an outstanding Research and Development Team, this makes them create reliable and trustable machines. Their variety of products includes:

1) Air Bubble Machine (2-10 layers)

2) PS/PE Foam Sheet Extrusion Line

3) PP/PC Hollow Profile Sheet Extrusion Line

4) Automatic Cast PE Breathable Film Extrusion Line

5) Rigid Sheet Extrusion Line

6) Reclaim System

Their reputation is not only within Asia, but also to a worldwide level, which help their machines to have a presence in every continent around the globe. Another advantage CCM has is that, to assure quality their warranty it covers for all machines up to one year, but also after the end of it, still provides after service.

The current global situation create many and different challenges to most of sectors in the industry, one of the main challenges, is the environmental protection, to face this, CCM machines have 0% materials waste, this achieved thanks to the expertise in machine design, providing the customer assurance that 100% of their materials will be used during production.

Another challenge that CCM just like most of Taiwanese manufacturers are facing is the reduction of cost, since to assure quality, all their machine parts are manufactured in Taiwan, in this way customers can have certainty that the machinery they are buying meets the highest quality standards and inspection process.

CCM has one uniqueness and it is that thanks to their high experienced team, are able to customize 100% of the machines their manufacture, making them able to solve any request from their customers, assuring quality and their designs.

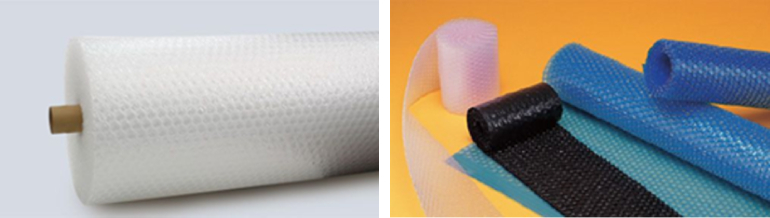

Air Bubble Machine

One of their main products that CCM manufactures is Air Bubble Machine, they have the capacity to produce from 2 up to 10 layers of final product with sheet width able to fit customers’ needs from 1,200mm to 2,500mm. Also if other specifications are required, CCM specialist team can help you with customize machines to meet your demands.

The main applications of Air Bubble Sheet produced by CCM are:

1) Agricultural sector with anti-UV additives.

2) Laminated with paper, PE woven and aluminum foil for making envelopes.

3) Packaging of electronic material with anti-static additives.

4) Swimming pool cover with anti-UV additives.

5) Typical packaging with anti-shock, anti-abrasion and anti-crushing functions.

For more information about CCM Air Bubble Machines, please check the link below:

AIR BUBBLE MACHINE

PS/PE Foam Sheet Extrusion Line

Another specialty CCM provides within their product range is their Foam Sheet Extrusion Line, which provides excellent thermal insulation, which helps to keep the temperature into stable levels; Low water and humidity absorbance that will assure that the packaged products keep their quality in high levels; also can be expected High compression strength and mechanical resistance.

One of the main concerns of the customers is the stability of dimensions and Homogeneous density, with CCM machines these will not be a problem, since thanks to its high quality standards users can assure to accomplish both stability of dimensions and homogeneous in density.

The output capacity will vary depending in the material customers decide to produce on it, as below:

| EPS: From 200 kg/hr to 720 kg/hr. EPE: From 120 kg/hr to 500 kg/hr. |

|

For more information about CCM PS/PE Foam Sheet Extrusion Lines please check the link below:

PS/PE FOAM SHEET EXTRUSION LINES

PP/PC Hollow Profile Sheet Extrusion Line

One of the main expertise of CCM is their fully computerized sheet and film extrusion and co-extrusion, with over 47 years of experience manufacturing, their high qualified team of engineers, operators and technicians, continuously work researching about the latest trends on high extrusion technology to meet day by day customers’ requirements.

Thanks to their uninterrupted efforts to be in the vanguard of the industry, CCM new generation is able to produce PP hollow profile sheet with a thickness between 2mm to 12mm in the two-layer option, with a width between 1200mm and 2200mm, and an outstanding output up to 500k/hr.

Within CCM Hollow profile sheet machine users can expect to produce different goods such as Advertisement board, exhibition board, packaging material, house decoration, stationery accessories, static prevention board, fruit and seafood boxes.

If you want to get more information about CCM PP/PC Hollow Profile Sheet Extrusion Line, please check the following Link:

PP/PC HOLLOW PROFILE SHEET EXTRUSION LINE

|

| Official Website https://www.extrusion.com.tw/en/index.html Chi Chang on PRM-TAIWAN https://www.prm-taiwan.com/com/chichang.html |

Extruders and Extrusion Lines

- Air Bubble Film Extrusion Line

- Air Bubble Film Extrusion Line

- Air Bubble Sheet Co-extrusion Line

- Bag Making Machines

- Blow Film Making Machine

- Blown Film Extruders

- Blown Film Making Machine

- Cast Film Machine

- Coating Machine

- EPS/EPE Foam Sheet Extrusion Lines

- Extruder

- Extrusion Laminating Machines

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Monofilament Extruding Machinery

- Monofilament Extrusion Line

- PET Strapping Band Extrusion Lines

- Plastic Bag Making Machines

- Plastic Film Co-Extrusion

- Plastic Pipe Making Machines

- Plastic Tube Making Machine

- PVC Hose Making Machine

- Straw Making Machines

- Twin Screw Extruder

- Twin Screw Extruders

- Woven Bag Making Machine

Plastic Recycling Machinery

- Bottle Washing Line

- Crusher

- Granulators

- Pelletizer

- Pelletizers

- Pelletizing Machines

- PET Bottle Recycling Line

- PET Hot Washing Line

- Plastic Pelletizing Machines

- Plastic Recycling Equipment for Preprocessing

- Plastic Recycling Machines

- Plastic Waste Recycling Machine

- Recycling Lines

- Recycling Machine

- Shredders

- Squeezers

- Washing Lines

- Waste Recycling Equipment