P-12

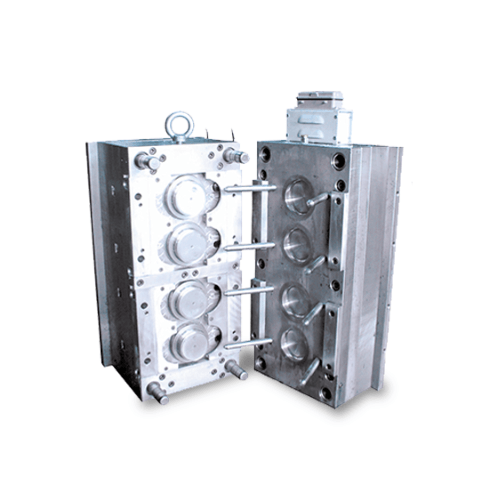

Categories : Injection Molds

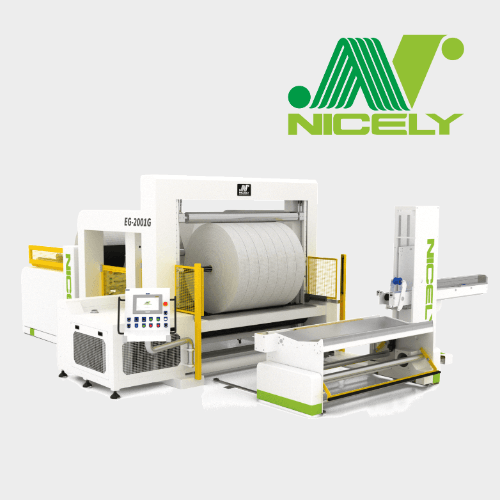

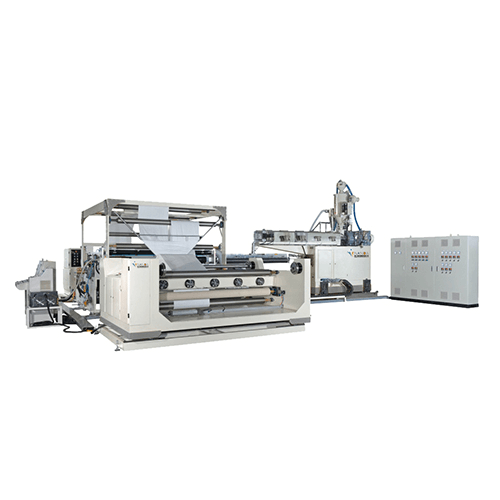

Extrusion Lamination With Turn Bar

● This machine is applicable for laminating PE / PP woven fabrics and sacks. ● A turn bar device makes a double side lamination one time with one extruder. ● Whole machine is synchronously controlled by PLC programmable, and easily operated through human mach

Thermoforming Packaging Machine

Categories : Contact Heating Thermoforming Machines

Thermoforming Packaging Machine from Jaw Feng Machinery Co., Ltd. is made of stainless steel, in line with food hygiene and safety. Durable transmission chain can clip the film more than 2 million times. Servo motor provides precise and fast forward. Multi-lingual PLC touch screen. Able to work with automatic filling machine, date injecting, date thermal printing, film easy to tear, water cooling machine, etc. Simple, easy change over for die sets; Custom die size. Automatic notice for insufficient film supply. High-speed production can reduce considerable labor costs. It can be used to package powder, paste, solid and liquid materials. We also offer a variety of options for this machine.

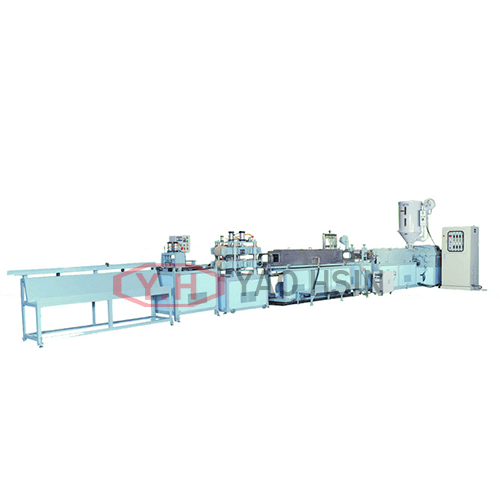

PP Strapping Band Extrusion Line (JC-SPP Series)

Categories : Tape Extrusion Machines

The JC-SPP series PP Strapping Band Extrusion Line designed for making PP polypropylene straps, commonly used for light to medium load packaging such as newspaper & magazine, carton boxes, pallets, and other industrial and consumer usages.

Conversion line (Gusseting-Cutting-Sewing)

Categories : Cutting Machines

The new generation of woven sack conversion line for bottom-sewn sacks is suitable for coated and uncoated woven fabric, and BOPP film laminated fabric. With great variety of options, a wide possibility of applications is brought for the customer.

Precision Gears

Categories : Gears

The world’s latest gear grinding instrument. Diversified precision gear profile modification technology ensures the best gear precision.

16-station Disc Machine YHL SERIES

Categories : Vertical Injection Molding Machines

The number of stations is developed according to customers needs with precise disc positioning.

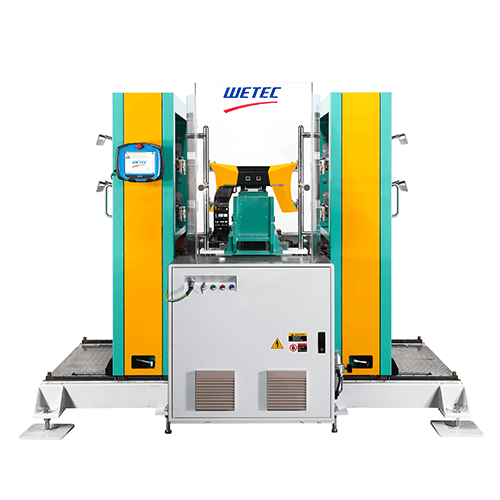

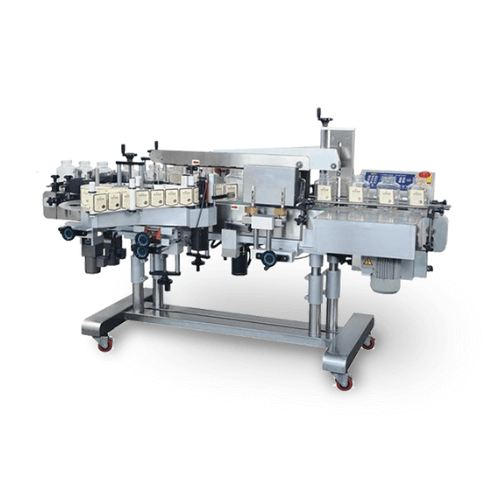

Auto Laminating Machine ALM-800

Categories : Cutting Machines

Synchronized automatic glass handling mechanism to speed up operational efficiency. Unique, special, patented pattern film laminating mechanism, to ensure no air bubbles after lamination process. Automatic cutting and partitioning mechanism to cut and partition laminated work pieces. Laminating length and speed can be programmed and adjusted to suit actual requirements. Optional single-side or double-side protective films can be laminated to suit actual requirements. With pattern paper recoil function to automatically recoil the pattern paper. Compatible with glass automatic feeding and automatic material take-up system.

Vertical Clamping Vertical Injection Machine-YH Series

Categories : Vertical Injection Molding Machines

- Four-column/vertical clamping, vertical injection. Rectangular shape between tie bars for easy insert. - Twin injection cylinder balanced for smooth and powerful injection. - Simple structure, small occupancy. - Double action clamping cylinder for fast clamping, slow speed high-pressure clamping. - Single sliding pushes the lower mold out for easy loading/unloading. - Double sliding use two lower mold, machine molding the parts while the operator is loading the other mold, to increase productivity.

Toggle Energy Saving Injection Molding Machine Servo 90E to Servo 570E

Categories : Horizontal Injection Molding Machines

● Effective Energy Saving Unit ● Outstanding Hydraulics ● ASE Servo Pump

Single-Stage Injection Stretch Blow Molding Machine - ISB Series

Categories : Injection Blow Molding Machines

GF/ISB series adopts the world's most advanced single-stage injection stretch blow molding machine technology. One single machine is able to achieve high quality and efficient productivity. Compared with two-stage PET machines, GF/ISB possesses several advantages. Golfang

5 Gallon Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging

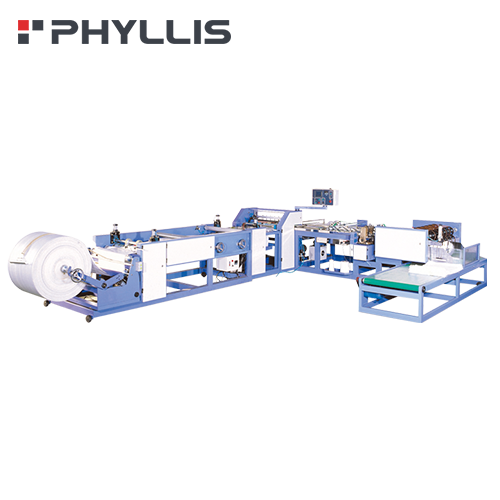

PP Woven Bag Related Machinery - JLJBCM SERIES

Categories : Plastic Bag Making Machines

Alloy steel knife for good cutting section Equipped cross or circle punching device Customized design

PET Stretch Blow Molding Machine - TEM12S2

Categories : Automatic Blow Molding Machines

Blower power consumption for 1000 bottles: 2Wh Air Compressor power consumption for 1000 bottles: 6 kWh compact space Screw driven controlled by servo motor providing fast and smooth motion Single lamp bilateral centralized heating, easy controlled within 3°C and energy heating Low-pressure air compressor will NOT be required due to high-pressure recovery system. High efficient air recovery system up to 45%

UNB Series-1300-1800

Categories : Industrial Robots

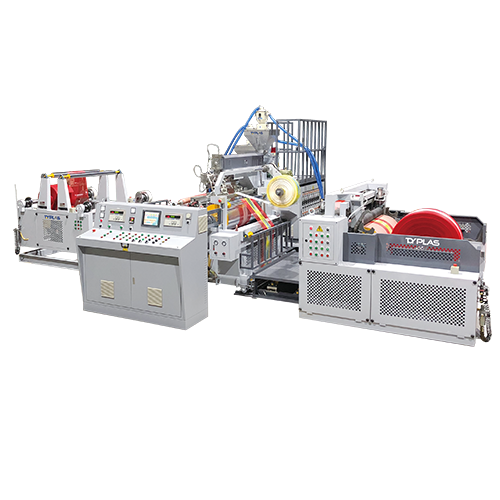

HDPE Super High Speed Blown Film Machine

Categories : Blown Film Extruders

King-Plus HES Series is designed to produce HDPE plastic film, while LES series for LDPE plastic film. These machines could give you advantages with high-quality, extraordinary mixing performance and high output capacity. With precise machinery design, they could work in efficiency state to realize the achievement of saving energy. HDPE & LDPE film is commonly used to shopping bag, garbage bag, surface protection film and barrier film etc.. There are some auxiliary options as like rotary die seat, auto loader, gusset device, embossing device and auto roll change device and so on, to build a especially-suitable blown film machine for you.

SINGLE-SHAFT TYPE SEMI-AUTOMATIC ALUMINUM FOIL & CLING FILM REWINDER (SRB-A-1S 20-50)

Categories : Slitters and Rewinders

SRB-A-1S, one shaft type semi-automatic rewinding machine. It's a strongly stable machine for rewind aluminum foil & cling film. Which is friendly, easy-operate for a novice. SRB-A-1S is compatible for cling film and catering aluminum foil. It can solve the temporary requirement when you need to exchange materials. The mother roll available width is from 200-500 mm. The max rewinding speed is up to 500M/min. The finished product can be 1000M the longest. Machine uses electric speed adjustments. You can control the rewinding time more precisely, arrange manpower more effectively. SRB-A-1S multiple functions rewinding machine brings you better operation and higher efficacy. Welcome to consult machine with us. We will at your service.

Automatic Servo C-Folding Perforating&Winding Bag Making Machine-RFCW1-SERVO-Series

Categories : Plastic Bag Making Machines

REE series is equiped two photo-cell & electric-magnetic clutch & brake, suit able for running two tracks of the printed film.

Onion Leno Bag Laminating Machine-TY-LMLB Series

Categories : Extrusion Lamination Machines

The main functions of the LMLB series can be made of two kinds of film at the same time. First is onion mesh cloth and printing leno through the lamination for bonding in the middle. Second is to laminate the film about 70-100 mm wide at the side, and this side film will do hole-punching process and used as auto filling and packing.

8 Color Rotogravure Printing Machine

Categories : Rotogravure Printing Machines

For PP, OPP, PE printing and more.

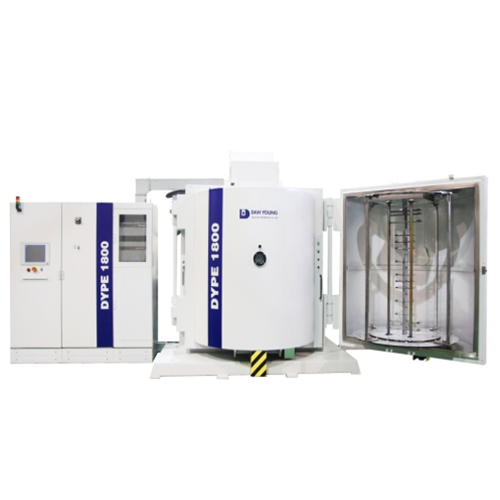

Heat Transfer Film for ABS Materials

Categories : Films

Various Plastic Products, CD Barrel, Container、Metal Outer case、House Ware、Stationer, Gift etc. All kinds of ABS plastic products can use heat transfer, as long as the surface is smooth and flat, the design and product can be perfectly combined. Heat transfer film has many function which direct printing doesn’t have. Using heat transfer film and heat transfer machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

High Speed Side Sealing Bag Making Machine-SE-SERVO-Series

Categories : Plastic Bag Making Machines

• With Multi-Function folding device for different type of side sealing bags. • Equiped with auto sensor, will stop machine as film run out.

UXIII-250/550

Categories : Industrial Robots

HDPE GRADE A / NATURAL

Categories : HDPE Resin

plastic shredder SP-420 / 60205

Especially for bulky plastic products. Eliminate the disadvantages of traditional high horse power crusher.Also for cracking unusual objects,waste tyres,logs,sleepers,etc. ● 2-shaft,claw-cutter breaker has the best ability to shred anything with low noise,vibration free. ● Auto reversible equipment to prolong the life of machine.

Extrusion Dies Lamination

Categories : Extrusion Dies / Dies Heads

EXTRUSION DIES LAMINATING DIES CFJ Width: 500 ~ 5000 mm Die lip span: 0.6 ~ 1 mm Extrusion capacity: 100 ~ 500 kg/hr Width adjustment: internal deckle system Die lip adjustment: manual or motor drive SUITABLE AVAILABLE POLYMERS INCLUDING EAA, EVA, PE, PET, PP, PS, Surlyn EXTRUSION DIES LAMINATING DIES CFC Width: 500 ~ 2500 mm Die lip span: 0.6 ~ 1 mm Extrusion capacity: 100 ~ 500 kg/hr Width adjustment: internal and external deckle, and others Die lip adjustment: manual SUITABLE AVAILABLE POLYMERS INCLUDING PE, PET, PP, PS EXTRUSION DIES WITH AUTO CONTROL Width: 500 ~ 5000 mm Finished goods thickness: 0.012~0.05µm Extrusion capacity: 100~500 kg/hr AVAILABLE POLYMERS INCLUDING BOPET, BOPP, Laminating PE

HA-1100SW

Categories : Industrial Robots

The whole machine used a linear slide drive Slide rails are equipped with automatic oiling device In line with the needs of high-speed machine design

Other Auxiliary Equipment

Categories : Control Equipment

Develop control system of other plastic machinery, such as extruder, bottle

MICRO MOLDING

Categories : Injection Molds

Micro molding is a very specialized art form, which is a kind of tooling design , manufactures small and precision plastic components with polymer-based functional devices, by increasingly demanded in the fields of life science, electronics, medical, photonics, automotive, and aerospace. The tiny-scale molding form of injection molding that entails building a cavity to match the shape of the part you want to make, sort of like the plastic molding that makes Lego bricks. THERE ARE THREE DIFFERENT THINGS TO KEEP IN MIND WITH MICRO MOLDING : Micro means the size of the part. It is the most common definition when dealing with micro molding. Micro features relates to tiny parts on a larger part. As a whole, the part can be big, but its components can be smaller, or micro features. Micro tolerance is how the parts are measured and how close to the needed measurement the part has to be to be considered a good or usable part. When a part is molded, it has to measure within the needed measurement (the tolerance), which could be as small as a thousandth of an inch. Small parts that are simple to make have tolerances that are not as tight and would be considered regular molding. SOME ADVANTAGES OF DESIGN GUIDE IN YOMURA AS : Dimension Aspect ratios around 6:1 (material dependent) Wall thickness : 0.3 mm ( 0.012”) min. for plastic Hole dimension : 0.2mm ( 0.008”) – 0.5mm ( 0.02”) min. Pitch of hole : 0.3 mm ( 0.012”) – 0.50 mm ( 0.02”) min. Tolerance (min) : 0.01 mm ( 0.0004”) – 0.02 mm ( 0.0008”).

FILTER NOZZLE

Categories : Nozzles

The filter nozzle was installed in the front tip of the injection molding machine barrel and using different types of inserts lead to reach effectiveness of filtering impurities. Prevent the runner gate from clogging. Filter impurities. Easy to be installed and maintained.

Edible Oil Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging