AUTO ROTARY SEALING MACHINE-ET-85

Categories : Sealing Machines

1. PLC with Index Gear Conveyor, Inverter Speed Control and Touch Screen Operation. 2. Stainless Steel frame and Anodized Aluminum.

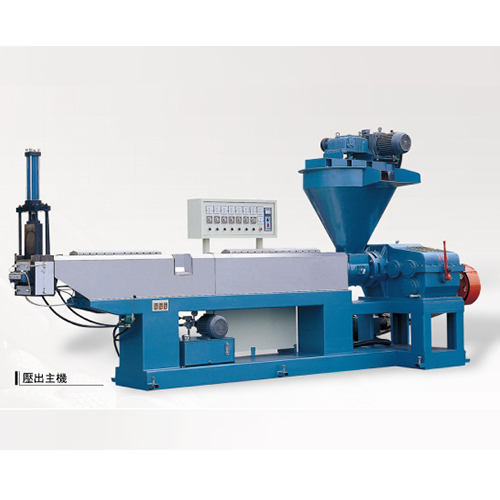

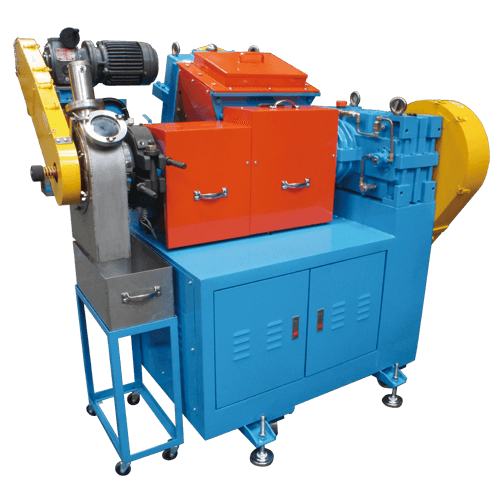

LAB EXTRUDER-Pelletizer (PR-50)

Categories : Plastic Pelletizer Machines

One of our main products, this can be attached to numerous different machinery lines, including pelletizing lines, master batch machines and compounding machines. Our machinery can process many different kinds of pellets including: (EVA, HDPE, PVC, PE, CaCo3 Sulfur etc) The PR-series is a combination of twin-screw feeder and extruder, which is able to process a round mass of raw materials produced by a banbury mixer. This twin-screw design feeds raw materials so stably that it’d decrease the risk of material supply shortage, and further, it’d increase both the yield rate and product quality. Besides, it would create a stable production line by reducing your labor cost and time with this unique design.

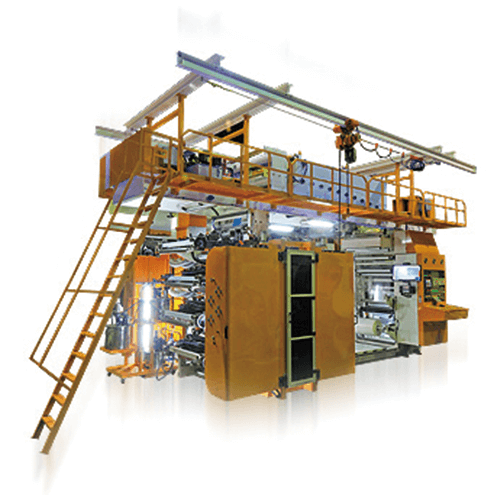

DPM-The Shaft Driven Press

Categories : Rotogravure Printing Machines

DPM ( The Shaft Driven Press) The press is an economical solution for gravure printers. This is the basic model in the rotogravure class. The press is driven by shaft for the registration control. If you are looking for a shaft driven rotogravure press, this is the press for you to customize

Inverter / Inverter Duty Motor-VFEF Series

Categories : Motors

Higher precision motion control and speed adjustment to make the machine in automation, high production capacity purpose.

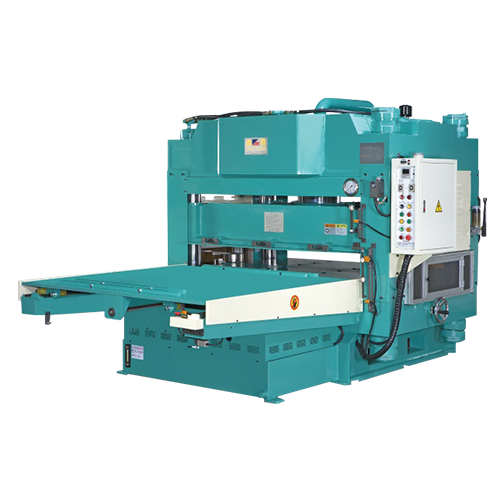

Precision Hydraulic Four Column Type Automatic Feeding Cutter - CSS-806A

Categories : Cutting Machines

Precision Hydraulic Four Column Type Automatic Feeding Cutter

Car Hemming Machine - YT SERIES

Categories : Vertical Injection Molding Machines

- Vertical clamping, horizontal injection, and large spaces between posts with strong structure. Easy to disassemble large molds.

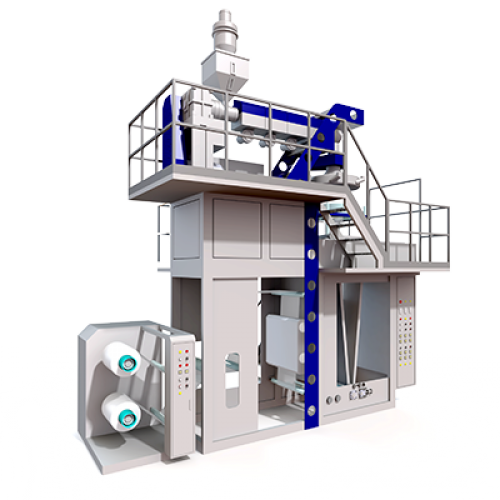

Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Horizontal Blow Molding Machines

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome. Co-extrusion application is the advanced technology by the leading brand: Full Shine.

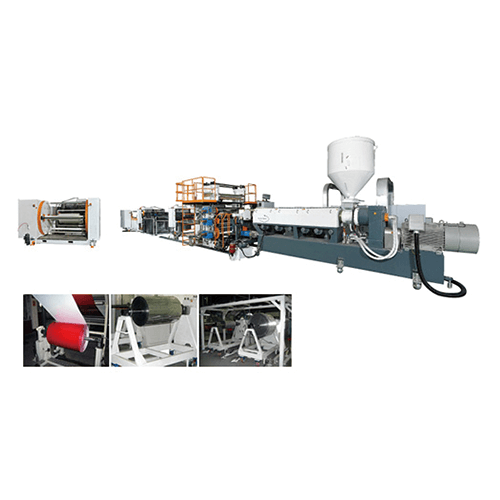

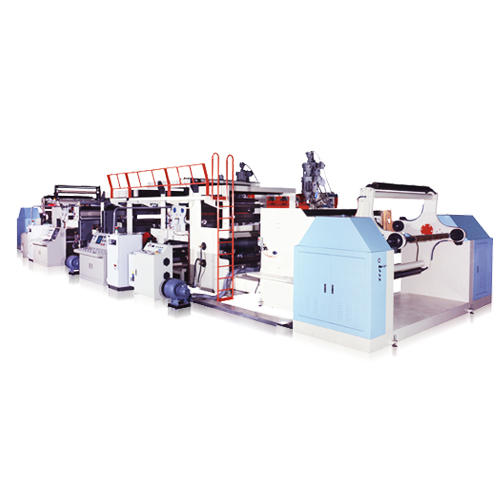

Laminating-Machine-HC110-2LM-80C1.6

Categories : Extrusion Lamination Machines

Extrusion Capacity:350 Kgs x 2 Sets = 700 Kgs/Hour, Extrusion Capacity:150 Kgs x 2 Sets = 300 Kgs/Hour Line Speed:40-220 Meters/Minute Laminating Width:600MM~1600MM

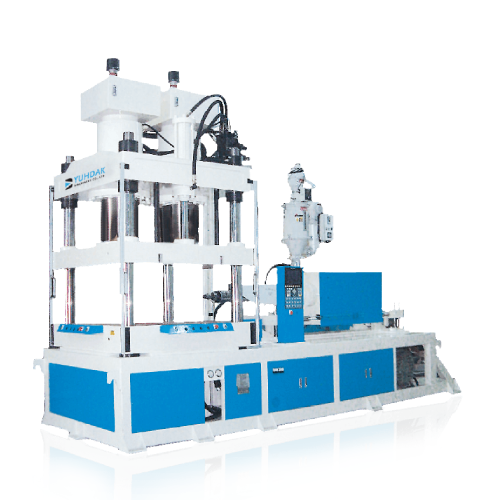

Rubber Back-Injection Molding Machine

Categories : Rubber Injection Molding Machines

Rubber Back-Injection Molding Machine Nature rubber Rubber of metal boned parts Oil resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber

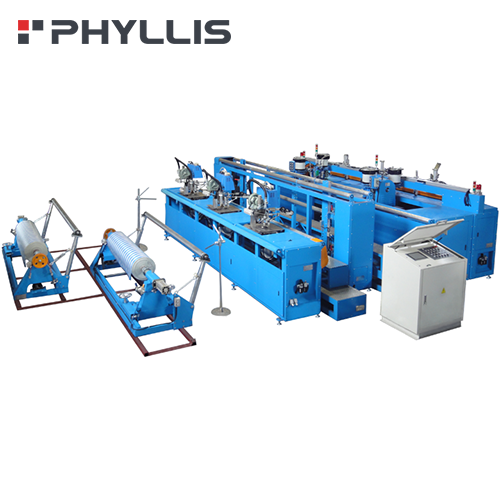

PP Woven Bag Conversion Line - JLCSHM SERIES

For BOPP bag or lamination woven bag Automatic Handle-inserter & sewing Patents Design Future trends

PET Stretch Blow Molding Machine - TEM04M1

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

P-04

Categories : Injection Molds

S-13

Categories : Injection Molds

P02

Categories : Injection Molds

CNC Servo Robot-W6 Series

Categories : Industrial Robots

Bus control Multi-language programming Free programming of every axis during operation Freely programmable safety area. Main programs and peripheral programs can be run simultaneously Big capacity: up to 500 programs can be stored Integrated observation of maintenance intervals Standard E67, E12, & SPI interface Different programming levels Analog vacuum switch to provide part recognition in the EOAT Shortest training time for operators

P-17

Categories : Injection Molds

CE Certificate Rubber Back-Injection Molding Machine

Categories : Rubber Injection Molding Machines

A special design of two-stage material supply is adopted. It expels bubbles out of the raw material in the most effective way and there is no dead material.

ULTRA LOW ENERGY DRYER

Categories : Dryers and Dehumidifiers For Plastic Materials

The first ULTRA Low Energy Dryer for plastics. Ultra-low kW energy usage - fast ROI and savings for a lifetime. Drying costs so low, it’s almost free Energy efficient unique vacuum drying technology Faster drying, faster start-ups, minimal maintenance

Tarpaulin Making Line (Automatic Line)

Categories : Film and Sheet Extrusion Lines

Our automatic tarpaulin making line is designed to weld multiple rolls together with 2 side eyeleting, and cut to desired length simultaneously.

Automatic Electronic High Speed Garbage Bag Making Machine-KFN4-SERVO-Series

Categories : Plastic Bag Making Machines

● With this sealing & cutting machine, each sheet folds automatically. It save time and labor. ● Number of sheets to be processed can set with auto-digital counter.

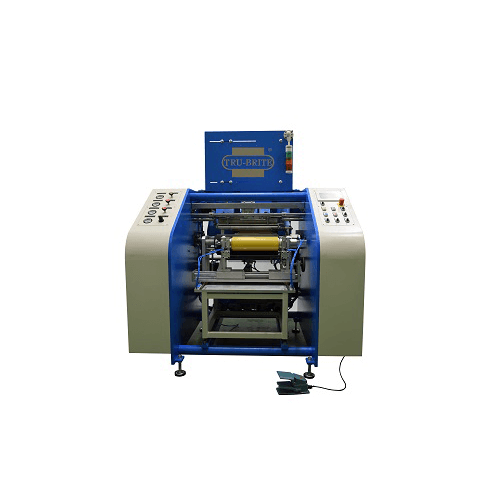

FOUR-SHAFTS TYPE AUTOMATIC CLING FILM REWINDER (ADJUSTMENT) (AH-FW)

Categories : Slitters and Rewinders

AH-FW, the four-shaft type automatic rewinding machine. It's suitable for rewind PE, PVC cling film. The machine specifications are customized accord to client's needs. AH-FW (20-30): Mother roll's available width from 200-300 mm; finished paper core's length from 210-310 mm. AH-FW (20-50): Mother roll's available width from 200-500 mm; finished paper core's length from 210-510 mm. It's a fully automatic model. Users only need to input paper cores and materials, machine will feed material, rewind, cut and unload finished products automatically. Besides, it has various switches: Auto/Manual mode Press roller ON/OFF Feeding ON/OFF Brake ON//OFF Small press roller ON/OFF With the above switches, it will be fast and convenient to adjust machine. What’s more, AH-FW has a curling device. The device will make a curl at the end of the roll, makes it convenient to start using the cling film. Machine shows total data and production values on the touch screen, users can control the machine status anytime. Welcome to consult machine with us. We will at your service.

Heat Transfer Film for PP Materials

Categories : Films

All kinds of plastic products made of PP can use heat transfer, as long as the surface is smooth and flat, the design and product can be perfectly combined. Now on the market, many pattern on the paint bucket is use heat transfer technology. Heat transfer film has many function which direct printing doesn’t have. Using heat transfer film and heat transfer machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

PC / ABS Alloy - CA6472B

Categories : Alloys

General purpose, black colored. Application: Electronic, Electrical cases, Thin-wall application, Automotive parts.

PET Stretch Blow Molding Machine -TEM16S2

Categories : Automatic Blow Molding Machines

Blower power consumption for 1000 bottles: 2Wh Air Compressor power consumption for 1000 bottles: 6 kWh compact space Screw driven controlled by servo motor providing fast and smooth motion Single lamp bilateral centralized heating, easy controlled within 3°C and energy heating Low-pressure air compressor will NOT be required due to high-pressure recovery system. High efficient air recovery system up to 45%

PET Stretch Blow Molding Machine - TEM06M1

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automaticalFEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.ly arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

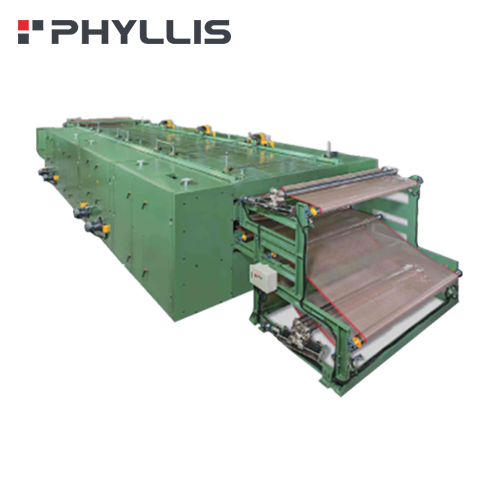

Pressing and Drying Section

Categories : Non Woven Production Line

A complete pressing and drying section including heat pressing rollers, oven dryer, embossing rollers, cooling system, accumulator, cutters, winders, and other peripheral equipment. It furnishes the final product with different extent of hardness and touches.

Small Electric Motor Continuous Operation Type - IK Motor

Categories : Motors

A small induction motor is an ac electric motor, which performs for directional and continuous operation by connecting single phease AC power or three phase AC power. Small Induction motors can support wide application and industries in packing machine, food machine, conveyor machine system, coding machine, cutting machine, sealing machine, sealing machine, etc. All products are made in Taiwan with high quality and our high-strength design makes motor maximum permissible torque up to 200kgcm.

AC Induction Servo Motor: SB Series

Categories : Indicators and Sensors

Frame size: F#180. Insulation:IP54 Low inertia design which could meet high precision motion control requirement by using servo drive system or closed-loop vector control inverter.

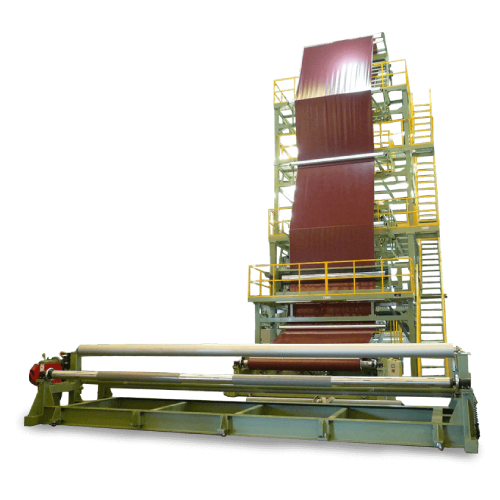

Agricultural Film and Geomembrane Blown Film Machine

Categories : Blown Film Extruders

The films is greatly helpful in agriculture and geomembrane. - Greenhouses that could increase the temperature to improve the growing environment and increase the available areas for planting, especially in high latitude and cold regions. - Mulch films could prevent the soil moist loss and preserve the temperature to keep soil warm that provide a suitable environment for seeds and sprout. - Silage films and stretch films is also more popular to store silage, hay and maize. - Geomembrane film could used to the construction for preventing leakage, water diversion for irrigation and reservoir and non-slip at side slope. Specification Layers: 3 / 5 layer Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. Opened film width range in 6 - 20 meters Designed output range 600 - 2000 kg/hr

Solventless Laminating Machine

Categories : Industrial Lamination

THE SOLA SERIES SOLVENTLESS LAMINATING MACHINE IS PERFECT IN SOLVENT-LESS LAMINATION FOR SHORT AND LONG RUNS. THANKS TO ITS SHAFTLESS UNWINDER AND REWINDERS, JOB CHANGEOVERS HAVE NEVER BEEN FASTER AND EASIER. THE SOLA SERIES SOLVENTLESS LAMINTAING MACHINE IS THE PERFECT COMPANION TO OUR RPM SERIES FLEXO PRINTING PRESS.

Long Sheet Cutter (Conveyor Type) With Two Side Trimming Device, Platform And Winding Device

Categories : Foaming Machinery

It is specially designed for cutting flexible long block into thin sheet and winding foam into roll for quilting or laminating purpose.

PP Blown Film Line(JC-PB Series)

Categories : Blown Film Extruders

JC-PB Series Blown Film Extrusion Line is downward inflation water cooling line for production of high clarity PP film.

C Type / Tie-barless Rotary Table - YC Series

Categories : Vertical Injection Molding Machines

C Type / Tie-barless Rotary Table - YC Series - C-type structure, the deformation is small. Easier for insert molding.

Coating Dies Slot / Slit

Categories : Extrusion Dies / Dies Heads

Slot/Slit design, excellent manifold geometry design, solvent resistant alloy, super mirror grinding technique SUITABLE APPLY TO Water Base /Oil Base / Non-Solvent Type Liquid Straightness precision is made by GMA exclusive grinding technique to reduced film thickness deviation of groove width. Interchange shim for variable lip gap application. Special stainless steel resists to a full range of solvents. Work with automated controller. Manifold geometry simulation analysis technique and optimum manifold design base on customer’s material. Uniform and stable flow distribution. No coating line defect with even thickness at high speed. Professional Slot Die maintenance service by third parties is acceptable.