Polyamid 66 - NB7200G33

Categories : PA(Polyamide) /Nylon

Glass fiber 33% reinforced, high flow, black colored. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

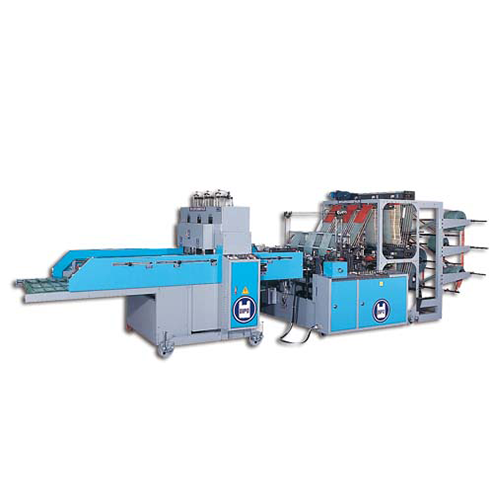

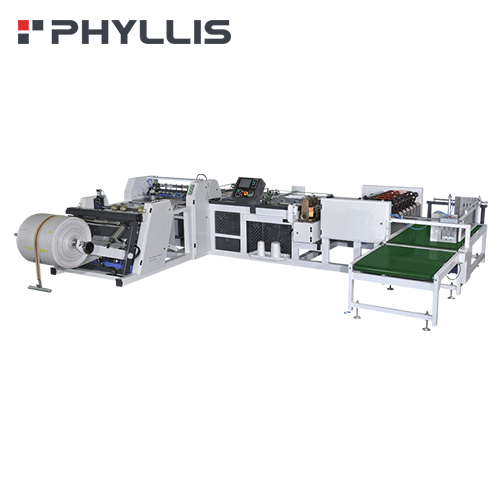

Double Layer High Speed Multi Lines/T-SHIRT Bag Making Machine-KDP-SERVO-Series

Categories : Plastic Bag Making Machines

● Ldeal for sealing and cutting super-thin bags as well as T-shirt bags. ● Electromagnetic clutches and breaks ensure accuracy of bag sealing and cutting.

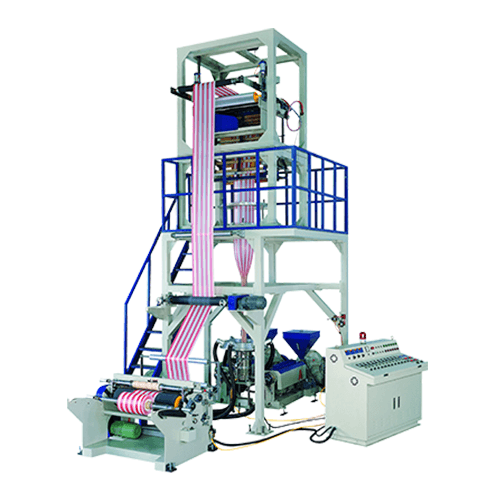

Two Color Striped High Speed Blown Film Machine - HDF-H-2

Categories : Blown Film Extruders

● Two independent extruders. ● To produce film with two colors stripes.

DG250 Mini Injection Molding Machine

Categories : Automatic Injection Molding Machine

1.Humanized Operation Panel 2.Aut-lubricate System 3.Injection System Adopts Precision Linear Sliding Track 4.Injection Purge Cover 5.Hopper Move-out Device

Flame Laminating Machine

Categories : Extrusion Lamination Machines

The SA-6AF flame laminating machine is laminating equipment for laminating foam sheet with various type of fabrics by using gas burner. The burner installed over the whole working width and melts the surface of foam to be contact with the carrier material and produces like an adhesive on the surface for laminating. laminating foam sheet with various type of fabrics

Three-layer Co-extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

Polarizer Bonding Machine GFL-20

Categories : Extrusion Lamination Machines

High Rigid Body Design: Higher workpiece machining accuracy. More stabilized bonding range. Higher accuracy. Smooth Bonding Process: The bonding process has been carefully designed in providing safe interlocking and higher yield rate. Automatic Film Stripping Mechanism (Optional): Automatic bonding film stripping mechanism in providing stabilized action and higher efficiency. Patented Bonding Mechanism: Special bonding mechanism is designed to achieve higher bonding accuracy and air bubble free effect.

S-03

Categories : Injection Molds

Disc Coupling

Categories : Gears

(1) NO-LUBRICATION REQUIRED: No lubricants are needed and no noises or wear and tear produced because there is no sliding or friction. (2) MAINTENANCE-FREE: ”LEAVE IT FOR GOOD AFTER INSTALLATION” It lasts forever as long as is used correctly. (3) LIGHT WEIGHT W/HIGH TORQUE: By operations, it is available in a wide range; it can be made of aluminum alloy to reduce the weight. (4) LARGE OFF-CENTER ALLOWED: With large range of off-centering, it can be used flexibly in all kinds of transmission systems. (5) SUITS HIGH-TEMPERATURE APPLICATIONS: All-metal-pars construct makes it suitable for high temperatures. (6) BACKLASH-FREE: WITH GOOD TORSIONAL RIGIDITY Perfect for axial rotation that requires accuracy and machines with phase-control. (7) CAN BE USED IN EVEN HIGHER SPEEDS: It is highly balanced due to being backlash-free and light weight. (8) EASY TO INSTALL: Comprising small number of pasts and being compact, it can be installed/uninstalled quickly. (9) ROBUST STRUCTURE AND HIGH SAFETY COEFFICIENT: With load stress kept at low standard, it works with very high safety coefficient. (10) AUTOMATIC PROTECTIVE DEVICE: In case of damage, an automatic protective device rotates via pads.

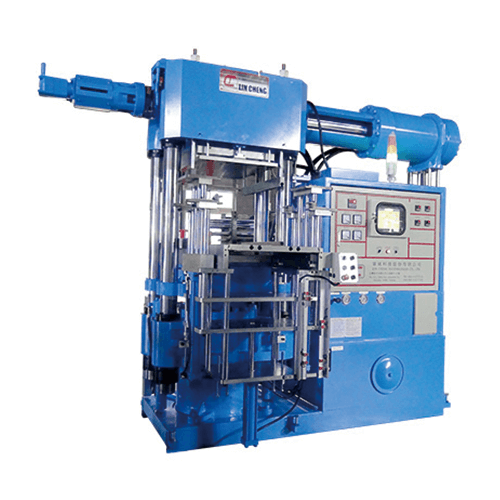

Vertical precise Rubber Injection Molding Machine with Inline Screw (first in -first out)

Categories : Rubber Injection Molding Machines

• Material charging by vertical screw and plunger cylinder, first in -first out , keep the fresh material into the mold, avoid curing in the barrel. • Barrel temperature controlled by built-in water temp. controller (within +-0.5 C).

Primary Packaging–General - Filling/Closing - AFC-60V

Categories : Capping Machines

The liquid packaging equipment compliances with cGMP liquid production guidelines and the common application is for below 60mL low viscosity products.

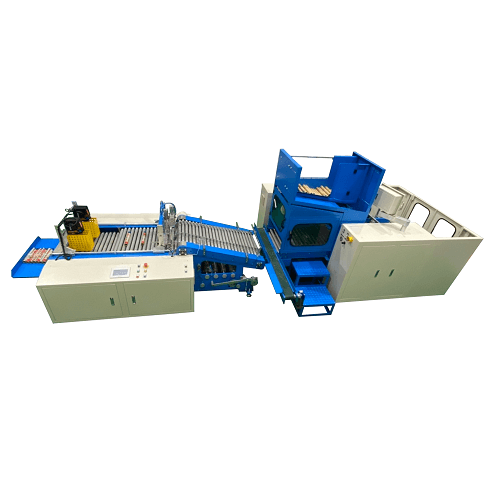

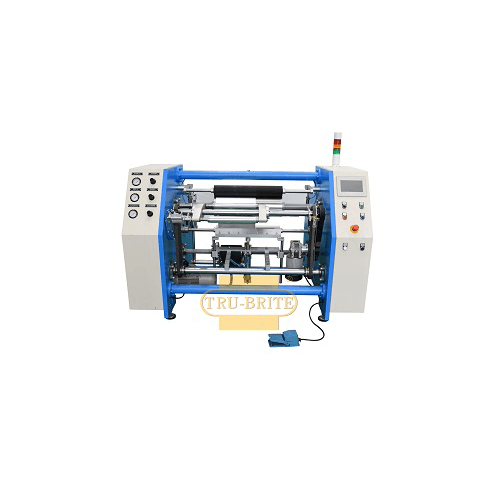

SIX-SHAFT AUTOMATIC ALUMINUM FOIL / CLING FILM REWINDER AUTOMATIC REWINDING & SHRINK FILM PACKAGING MACHINE (AH-6S + TPG50)

Categories : Slitters and Rewinders

AH-6S connected to TPG 50, the fully automatic production line, fully automatic operation system. Use a conveyor to combine two models for manufacture. Machine will automatically rewind material after input paper core. When the roll is finished and unloaded, it is carried to the packing area for automatic packing process. If the packing function is not used temporarily, TPG50 can be switched to delivery mode. Or use the conveyor which connects 2 machines to unload products from the side. This production line achieves automated manufacture. It saves time and manpower of moving materials and rolls from machine to machine. TRU-BRUTE Machinery always provides the beneficial collocation of machine for you. Welcome to consult machine with us. We will at your service.

S-16

Categories : Injection Molds

3RT Mold-Open Rubber Injection Molding Machine IRH-S3

Categories : Rain boot Injection Molding Machines

Mold opening design The 3RT surpasses the traditional top opening mold that can be used for the triple or four molds with the design of the opening mold and pushing out the mold in the between. The opening mold can be adjusted by the software with separate opening, separate pushing out the mold in between, continuous opening and continuous pushing out the mold in between. Injection volume control High precision optical ruler is adopted for precisely calculating and controlling. Design of rotary injection board Special designs for loading/unloading functions are provided. It causes no dead material in the injection nozzle. It is easy to clean the material. It is durable and the quality is stable. Safety design A high-tech infrared safety electronic sensor and automatic warning system are adopted to monitors the status of machine in order to provide extra protection to ensure the operation safety for operators. Hydraulic system Design Hydraulic system Designed by proportional pressure and flow ratio, which is steady, quiet and low frequency of malfunction. Two shafts can be operated simultaneously.

Automatic Feeding And Laminating Machine ALM-700

Categories : Cutting Machines

Unique feeder mechanism to enable lamination and processing by operators without having to keep up with machine operating speed. Unique, exclusive, patented film laminating mechanism to ensure no air bubbles after lamination process. Automatic cutting mechanism is capable of having a specified length programmed for cutting operation. Laminating length and speed can be programmed and adjusted to suit actual requirements. Singe-side or double-side protective films can be laminated to suit actual requirements. With pattern paper recoil function to automatically recoil the pattern paper. Optional roll to roll or roll to sheet lamination.

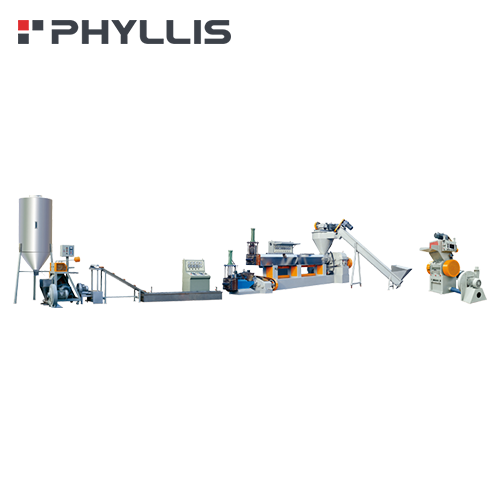

Recycling Line (Pelletizing)

Categories : Plastic Pelletizer Machines

The recycling line transforms re-granulate to pellet form as a valuable secondary resource which could be used again in production. It helps the customer reduce the percentage of waste materials produced during manufacturing, and creates sustainability for our environment.

KW-106 CAPSULE & TABLET INSPECTION MACHINE

Categories : Inspection Machines

KW-106 inspection machine is designed and used for inspecting capsule or tablet which is spotty, broken.

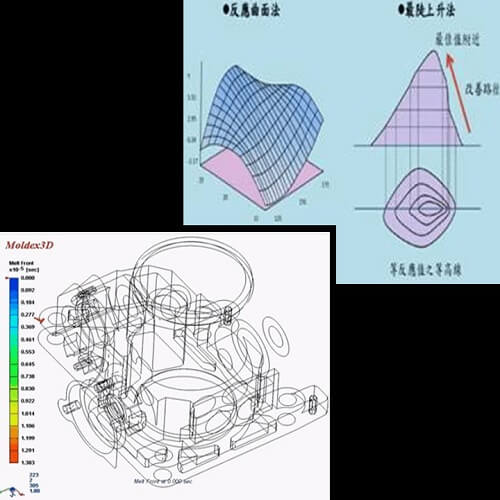

PROCESS OPTIMIZATION

Categories : Injection Molds

In-Mold Decoration (IMD) is an efficient, durable and cost effective technique for printing, painting, and forming plastic decorations. However, a large number of parameters involved IMD manufacturing processes and the complex relationship between these parameters make the determination of the optimal parameter setting a challenging task. This paper proposes a systematic framework integrating Response Surface Methodology (RSM) and logistic regression to improve the yield of IMD manufacturing process. The integrated framework becomes easy to identify the optimal parameter setting,saving a great deal of time and money in the manufacturing process. On the empirical study in collaboration with Yomura, the proposed framework shows the significant result from 10% to 87.5% validating the viability of the proposed framework in real setting. (Key words: IMD, In-Mold Decoration, Parameter Optimization, RSM, Response Surface Methodology, Logistic Regression) EXPERT ANALYTICAL SYSTEM Yomura Technologies employs state-of-the-art technologies to select materials, validate component designs, develop tool designs and optimize its processes, ensuring that innovative concepts are achievable at the lowest cost of production. (Keywords: Moldex3D, Moldflow, PowerMill Pro, CAD system)

Serrated Cutter

Categories : Industrial Knives

Polyamid 66 - NBE7200G30

Categories : PA(Polyamide) /Nylon

Glass fiber 30% reinforced, super high impact, black colored. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

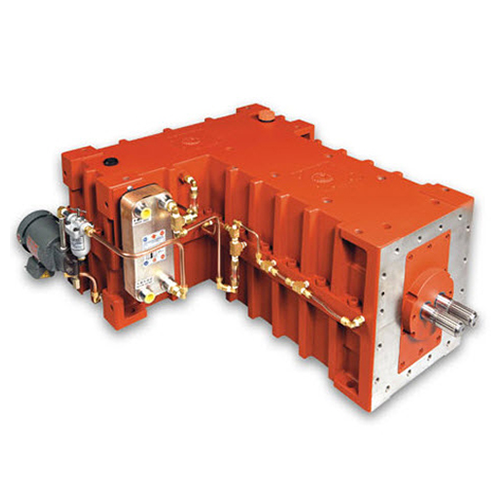

Super Torque Gearbox for Co-rotating Twin Screw Extruder

Categories : Gearboxes

Corresponding to the increasing demand of the twin-screw extruder, Sun Lung had developed the series of high performance gearboxes for the twin-screw extruder.

Conversion Line (Cutting-Sewing)

Categories : Cutting Machines

The new generation of woven sack conversion line for bottom-sewn sacks is suitable for coated and uncoated woven fabric, BOPP film laminated fabric, and leno fabric. With great variety of options, a wide possibility of applications is brought for the customer.

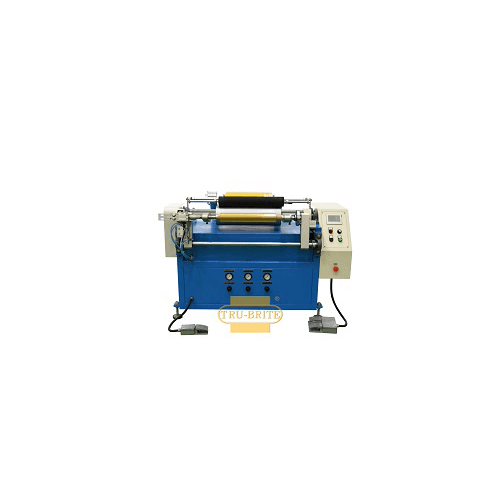

TWO-SHAFT TYPE SEMI AUTOMATIC CLING FILM REWINDER (SRS-2S 20-50)

Categories : Slitters and Rewinders

SRS-2S, the two shaft type semi-automatic rewinding machine. It specializes in rewind PE, PVC cling film. The mother roll available width is from 200-500 mm, and the finished paper core’s I.D. is from 25-76 mm. SRS-2S has a knob for adjust rewinding speed. Users can choose convenient functions. Such as automated start after press down the rewinding shafts; or changes shafts automatically. The PLC unit wisely assists user to run the machine. Machine is carried pedal controllers which have 4 functions: Mother roll chuck switch / finished paper core switch / rewinding shaft pressing switch / start switch. Various pedal switches, more convenient operations. Welcome to consult machine with us. We will at your service.

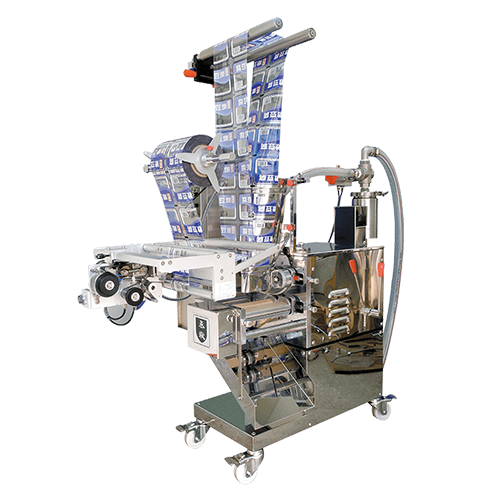

Liquid & High Concentration Sauce Packaging Machine - TYPE-857

Categories : Liquid Packaging Machines

• Application Products : Liquid : tea、juice、water、shampoo、soy bean sauce、bathing lotion、liquid sauce and other pure substance. Density : Tapioca、cream、jam、BBQ sauce、meat sauce、salad、facial lotion、chili、tomato sauce、butter and the similar. • Features : Automatic bag making → measuring → filling → sealing → cutting →finished products conveying. • Packaging Materials : Heat sealable laminated film (such as : Nylon + PE,OPP+PE,Alum foil + PE & other similar beat sealable film)

HomeProductsInverter / Inverter Duty Motor: GFEF Series

Categories : Motors

Foot mounted Insulation class: F class Suitable for general inverter applications Basic speed adjustment Reliable operation function Energy-saving and easy-maintenance

KW-B2 BLISTER PACKING MACHINE

Categories : Capsule / Tablet Packaging Machines

KW-B2 blister packing m/c applies the latest technology contribute to a low cost, low packing material consumption.....

Linux Based Internet of things Products

Categories : Industrial Software

Customer - centered, for the wide application of all walks of life to..

Corrugated Medium Liner / Medium Fluiting / Test liner

Categories : Cartoning Machines

- Our main products are Corrugated Medium Liner (GSM 112 to 150), Medium Fluiting (GSM 112 to 200) and Test liner (GSM 125 to 200). - Main applications for manufacturing paper carton box and paper bag. - Paper jumbo roll width can be slit as per required width. Maximum 4 meter wide.

PP IMPACT GRADE / BLACK

Categories : PP Resin

Auto Circular Horizontal Cutting Machine

Categories : Foaming Machinery

For cutting Flexible PU foam block with density under 50kg/m3, rebonded foam with density under 80kg/m3 and open celled PVC foam.

AT - 360

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 84~105 KW

S-08

Categories : Injection Molds

MULTIFUNCTION TWO-SHAFT TYPE SEMI-AUTOMATIC ALUMINUM FOIL & CLING FILM REWINDER (SRB-A-2S 20-50)

Categories : Slitters and Rewinders

SRB-A-2S, the two shaft type semi-automatic, multiple functions rewinding machine Suitable for rewind aluminum foil and PE, PVC cling film. The mother roll available width is from 200-500 mm. The finished paper core’s I.D. is from 25-50 mm. This model is carried a brake system, controls the brake power accurately. Users can check the data of brake output and single product weight anytime. SRB-A-2S is able to set prior deceleration points of every speed level. Users only need to adjust rewinding speed afterwards. Machine will regulate deceleration points automatically by the settings. It has automatic functions of cutting and fixed length feeding. Users will thread the material onto paper core more convenient. The whole machine is combined of electronic control, carried with electric motor system; enable more precise and quicker shaft-changing movements. While finished rewinding process, the rewinding shaft will back off by itself. Users can switch to the automatic mode which start machine automatically after shafts are pressed down. Automatic cutting, automatic shaft-changing and shaft pressing, users just need to load & unload products after press start button. Welcome to consult machine with us. We will at your service.

EX Series

Categories : Extrusion Blow Molding Machines

Advantage accumulator type - Design for big size products, but it is more stronger, more flexible to fit any kind of mold. Specialize in automotive parts.

Polyamid 66 - NBE1200G20

Categories : PA(Polyamide) /Nylon

Glass fiber 20% reinforced. Super high impact.

Hot plate heating type forming tools

Categories : Thermoforming Molds

Hot plate heating type forming molds is mainly for producing OPS products like containers, trays, and lids......etc. The post-treatment process is required for continuous trimming.