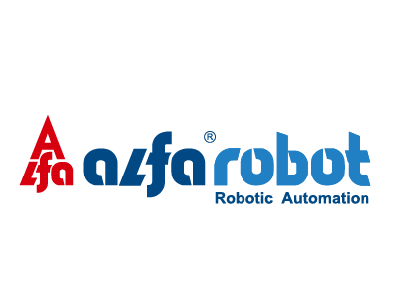

Calender for Rubber/Plastic

Categories : Calendering Machines / Mixing Mills

Sheeting for Rubber、Plastic & Chemical Industries This machine is used for sheeting produce for Rubber, E.V.A. or PVC and various kinds chemical material.

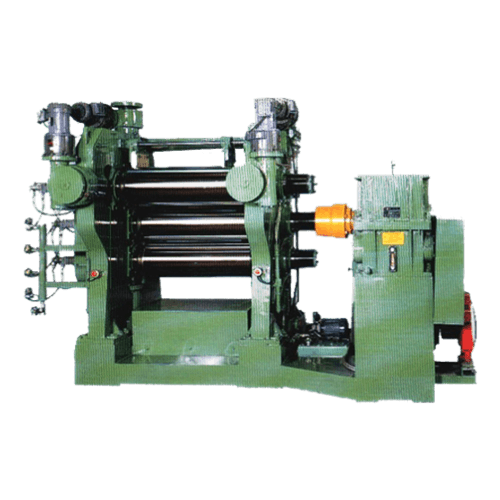

4 Roll Rubber Calender Machine

Categories : Calendering Machines / Mixing Mills

Four shaft gear couplings driven four roll inverted L Type Calender. The main use of Calender is to press the mixed and refinded rubber mixture or many kinds of plastic mixture into uniform-thickness of films, sheets, and plates. Also, it can be applied to rubber or plastic sheets in single or double sticking or topping operation with textile fabricas. Besides, in the procession of sheeting, the machine can also press out the air in the material for producing the products without air bubble after cure. The more quantity of rolls the calendar has, the more times of the sheets are pressed and the calendar can make high quality and even thickness of sheets. This is an four shaft gear coupling driven four roll inverted L type calendar. It applies to tire topping or friction and the manufacture of ball tubes and shoes. The operation of such durable and exquisite calendar equipment is very simple and can get high effects.

CNC AC Servo Beam Robots - Redstone Series

Categories : Industrial Robots

The Redstone series of robotic arms are used for various types of horizontal plastic injection molding machines of 50-800 tons. There are 3-axis and 5-axis AC servo drives. The product arm robot is for taking out products and runners. The vertical arm structures are single stage and telescopic stage, runner arm can be added to take out runner. The Redstone series of robots are suitable for high-precision, high-speed removal and embedding/insert, with fast response and high positioning accuracy for quick removal for single cavity and multiple cavities and embedding/insert applications.

CNC AC Servo Beam Robots - New Titan Series

Categories : Industrial Robots

The New Titan series of injection molding robotic arms are used in 650-4000 tons of various plastic horizontal injection molding machines, 3-axis servo drive, arm for taking out products, and the upper and lower arm structures are double-cut. Used for quick removal or a variety of removal applications.

Rewinding Machine FSR-800

Categories : Slitters and Rewinders

For re-reeling operation of slit rolls with uneven edges or tension. FSR Rewinding Machine will help you to achieve high quality re-reeling, even without the use of an advanced slitting machine. Especially ideal for an automatic filling packaging machine which requires a large reel diameter and rigorous tension quality.

Folding and Rewinding Machine-FND-R1000

Categories : Slitters and Rewinders

Especially designed for folding and rewinding processes of plastic films. The folded edge is neat and stable after rewound. This Folding and Rewinding Machine can easily transform flat film into folding form.

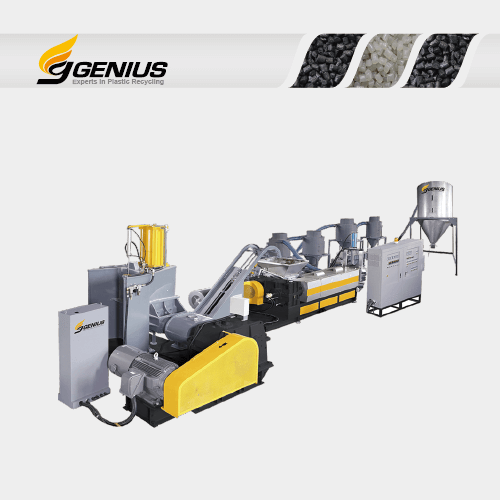

Side Entrance Single Stage Die-Face Type Recycling Machine & Palletizing Machine

Categories : Plastic Waste Recycling Machines

User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Crusher is optional. Low labor cost.

PVC Plastic Pellet Making Machine

Categories : Plastic Pelletizer Machines

Suitable for:PVC compound, rigid PVC, rigid waste recycle Soft PVC:DOP40%~100%

Water-Cooled Type PVC Pelletizer

Categories : Plastic Pelletizer Machines

Water-Cooled Type PVC Pelletizer, wpc pelletizing machine.

Twin-Cone High Speed Pelletizing Machine-Die-Face Cutting

Categories : Compounding Lines

Process Rubber/Plastic mixed material, EVA, TPR, PVC, CaCO3, PVB, PU, TPU compounding, various kinds of masterbatches pelletizing High capacity Low electricity usage Easy to clean and change materials Knead well Die-face cutting Adequate kneading

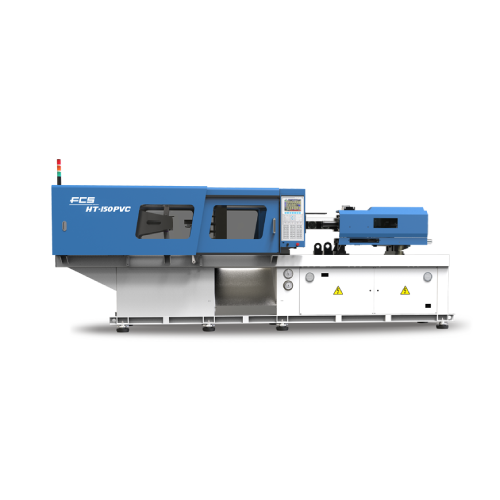

PVC Pipe Fitting Injection Molding Machine

Categories : Horizontal Injection Molding Machines

The PVC injection molding machine is for producing PVC pipe fittings used in building and construction industries, such as pvc socket, pvc tee, pvc elbow, pvc coupler, and pvc valve.

CaCO3 Compounding Plant

Categories : Compounding Lines

1.Drivetrain: High torque precision gearbox. 2.Extruder is equipped with pressure sensors. Replace filter screen as necessary. 3.Filler masterbatch is used to mix with a plenty of plastic raw materials to produce high-concentration masterbatch. 4.Applicable Materials: PP,LLDPE, LDPE, PLA, EVA, and PVC. 5.Maximum CaCO3 up to 80%~90%.