PET Stretch Blow Molding Machine - TEM06S2

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

PET Stretch Blow Molding Machine - TEM08S2-88

Categories : Automatic Blow Molding Machines

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. ● The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. ● Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. ● The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. ● Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. ● With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. ● Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. ● The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. ● Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

Inline Edge-Trim Recycler (JC-ECOTRIM Series)

Categories : Plastic Pelletizer Machines

JC-EcoTrim Series - Inline Edge Trim Pelletizing Unit was introduced on the basis to the subject of “Green Eco-Friendly” awareness to the film production industry. The unit cleverly integrated advanced structural design with innovative concept for pelletizing and reclaim of trimmed film edge uninterruptedly within its system. The process starting from edge trim feeding, plasticizing, pelletizing, cooling, and reclaim, all in one complete procedure promised to save labor cost, power consumption and process time.

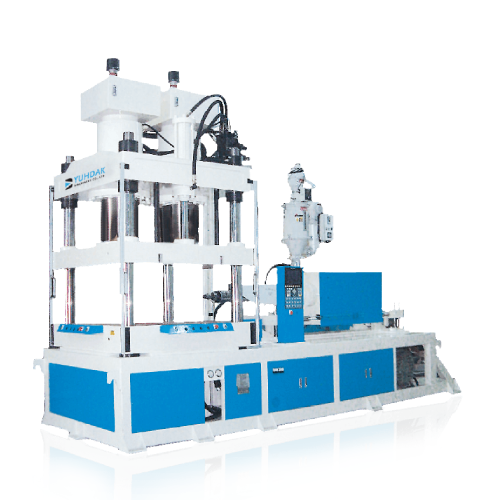

Dual Injection Low Pressure Molding Machine

Categories : Low Pressure Injection Molding Machines

Low pressure molding leads the way to protect fragile electronics components against moisture, dust-proof, moisture proof, insulation, temperature resistance, flame retardant, vibration reduction, well bonding, waterproof etc. Suitable for electronic components such as micro switches that require waterproof function, automotive electronic sensor.

Low Pressure Injection Molding Machine

Categories : Low Pressure Injection Molding Machines

Our LPM Low Pressure Molding Machine, CE marking certified, with its very low injection pressure 20~500psi (1.5~35 BAR) into the mold cavity and electronic parts to be encapsulated. Hot-melt Polyamide starts cooling down when it touches the cavity, then apply continuous injection pressure. The over-molding process will not harm any fragile solder joint of the circuit board (PCB Overmolding). At first, it's uses to replace toxic and bulky conventional potting processes, gradually spread to the world in market such as automotive market, medical, military, domestic appliance market.

Liquid Silicone Rubber Injection Molding Machine

Categories : Rain boot Injection Molding Machines

Applicable for the production of vehicle parts, electronic and medical goods, infant care and food products etc. Save time for production process and increase productivity. The best solution to support quality and efficiency. oxygen mask

Car Hemming Machine - YT SERIES

Categories : Vertical Injection Molding Machines

- Vertical clamping, horizontal injection, and large spaces between posts with strong structure. Easy to disassemble large molds.

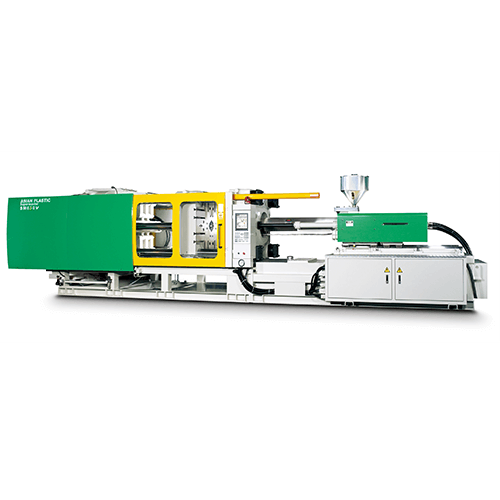

Heavy Duty Double Toggle Injection Molding Machine

Categories : Horizontal Injection Molding Machines

The new design has ensured maximum space between tie bars, as well as a large daylight area. The fixed and moving platens are designed in such a way that the yensure complete accuracy and precision. The injection carriage uses a balanced double hydraulic cylinder to provide a secure hold between the mould and the nozzle to eliminate nozzle leakage. Linear guide ways reduce mechanical friction, decrease machine wear and increases accuracy over back pressure providing better control of the injection sequence. Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportional valves is more precise resulting in more accurate control.

Dual Platen Injection Molding Machine

Categories : Injection Molding Machines by Platen

As a large tonnage injection molding machine, it can saves up to 20% of the machine floor space. (foot print) • Automatic mould adjustment saves on mould-changing time.

Medium Co-extrusion Blow Molding Machine

Categories : Electric Blow Molding Machines

Chen Way machinery is well-known for its 20L three layers blow molding machine. The recycle resins and the calcium carbonate (CaCO3) in the middle layer help to save material cost. Three layers M/C is the most popular choice for the edible oil export countries, production ranges from 5L to 30L jerry can. The outer and inner layer composed of 15%-20% virgin material and master batches. The middle layer can put around 60%-70% cost effective regrind material and also can add CaCo3 (no more than 30%), which can reduce cost down to 10-12% material cost. By contrast, the single layer jerry can only add around 5%-7% CaCo3 which has no evident improvement over material savings. Chen Way CWM

In Mold Label (IML Label)

Categories : IML

In-Mold label (IML) is widely used in food container because the ink is between two layers of film and normally produce in dust-free fab or air conditioning clean room to minimize the human touch. Using IML can do the injection and labeling the product at the time. So it is suitable for mass production and standardization.

Precision Four-Column Plan Hydraulic Cutting Machine-CSS-202B

Categories : Foaming Machinery

●The body of the machine is made of special steel and has gone through rigorous processing that shows a ram pressure-resistant function and precision. ●Up and down stroke applies steel pole as the rail that brings out an effect of high precision and shaking-resistant characteristic. ●A design of Two-pod oil cylinder shows the stable force and large torsion.