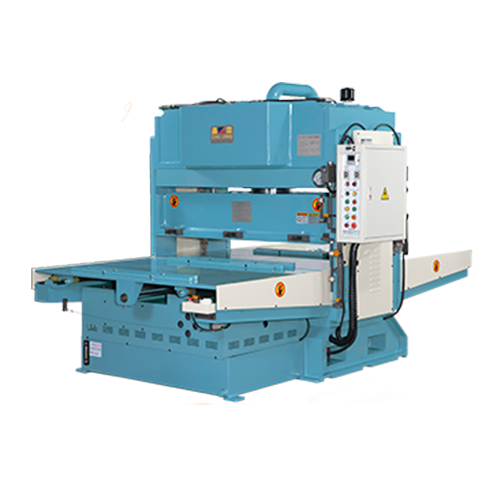

Precision Hydraulic Double-Sided Auto Feed Cutter CSS-806

Categories : Foaming Machinery

Both double-side and single-side operation, time and manpower saving, one machine for two purposes to give excellent effect of production. Double-side pressure and touch-type electronic counter watch are separatively deviced, so different sizes of product can be adopted. Super precision oil way design, silent for performance, stable location for each action, to increase the service life of parts and tool mold deviced with cutting board rotary table, the consumption of cutting board can de reduced. Body frame adopts high tension steel plate under stress relief process for long application without being deformed.(We welcome any special size from buyer).

Precision High Speed Hydraulic Automation Cutters-CSS-202

Categories : Foaming Machinery

● The machine adopts two-hand button, safe operation, fast, smooth, strong pressure, no noise, no vibration power, upstairs, downstairs plant can be used, low failure rate, improve production efficiency. ● Die automatic setting: Stroke is simple, fast and accurate, extending the life of knives and knives. ● automatic lubrication system: The use of mechanical parts can be automatically refueling, to ensure that mechanical damage, permanent security precision. ● Can be arbitrarily adjusted to determine the single layer. ● This machine is equipped with brake device to ensure the safety of personnel. ● special models can be customized.

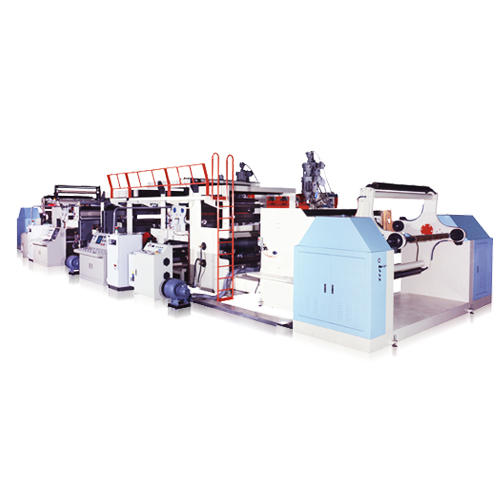

Laminating-Machine-HC110-2LM-80C1.6

Categories : Extrusion Lamination Machines

Extrusion Capacity:350 Kgs x 2 Sets = 700 Kgs/Hour, Extrusion Capacity:150 Kgs x 2 Sets = 300 Kgs/Hour Line Speed:40-220 Meters/Minute Laminating Width:600MM~1600MM

High Speed Precision Vertical Injection Molding Machine-YQ Series

Categories : Vertical Injection Molding Machines

• Vertical four-pillar vertical clamping, with vertical injection. • The square pillar design comes with large mold size. The space within the column allows customers to install devices of automatic embedding and removing products. This allows automation for the whole machinery. • Big L / D ratio of screw, plasticizing evenly, suitable for injection molding of engineering plastics. • High standard computer control system with high precision injection pressure and high response injection speed. The quality is more stable for high-precision embedded injection molding products. • 1S single sliding: After mold opening, the lower mold will automatically slip in front of the operator for facilitating embedded molding operation. • 2S double sliding (Alternating double sliding): One mold for injection molding, another mold for taking out and putting on embedded parts operation. • 2SL double sliding (90°Alternating double sliding): One operator can operate independently. One mold for injection molding, another mold for material taking and putting on embedded parts. The two slidings are intersecting at 90 degrees, which can lower the production cost, and enhance the performance. • Able to combine automation and the high-speed injection can effectively enhance the production capacity. • A variety of circuit design (half closed servo hydraulic or high speed injection) to meet the customer’s requirements.

High Speed Injection Molding Machine (TSV Series)

Categories : Hydraulic Clamping Injection Molding Machines

• The double hydraulic cylinder provides secure hold on pressurefor the injection carriage eliminating nozzle leakage. • The toggles are lubricated with the graphite bronze bushes to ensure lower friction wear, assure greater accuracy and greatlyextended life of the clamp unit. • Fast clamping system equipped with regeneration circuit increase speed by 60% to shorten cycle time and save energy. • Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportion-al valves is more precise resulting in more accurate control.

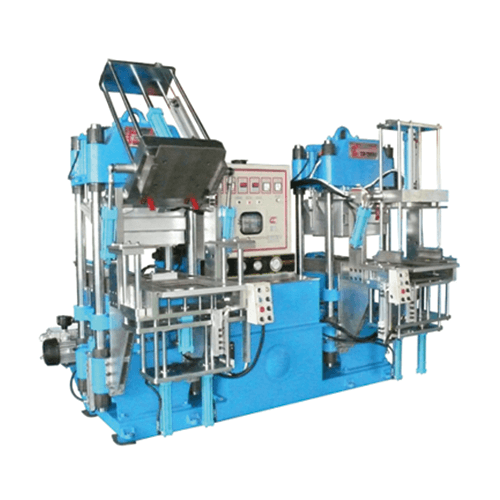

4RT Mold-Open Oil-Seal Vacuum Compression Molding Machine VOCC-D3W

Categories : Shoe Sole Making Machines

Design for machine frame The machine frame is made of steel plates through assembly. It is suitable for the production of oil seals. Design for loading/unloading molds Abrasive components are installed on the frame for loading/unloading molds. It can be frequently used and it’s positioning is very accurate. Design for vacuum room A vacuum gate can be opened or closed very quietly and smoothly. The tightness is excellent and it is capable of being high percentage of vacuum. Design for oil tank The vacuum room and the oil tank are separated to make oil seals more durable. Design for final products Two openings are designed for final products, top and bottom. The operation is easy and the production speed is very fast. Maintenance All positioning switches are installed outside the vacuum room. It becomes more durable and it is easier to perform the maintenance work. Oil system design Each oil system is designed respectively. Two shafts can be operated simultaneous.

Flat Type Mask Making Machine

Categories : Bag Making Machine by Applications

3 or 4 layer flat type face mask making machine. Improved design from one-to-three synchronized setup to one-to-two synchronized setup, to reach optimum production rate of face masks, while reducing the overall machine price, and occupying less working area.

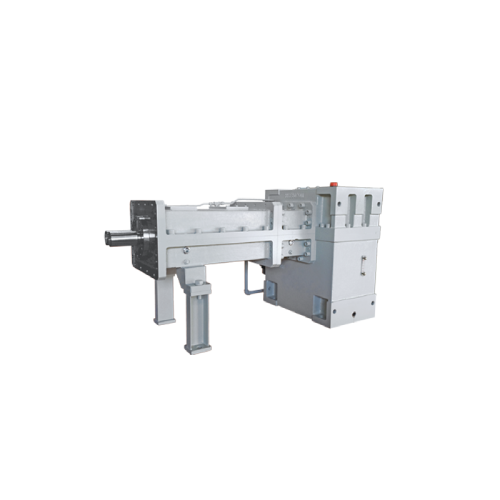

Twin Screw Extruder - Counter Rotating Type

Categories : Gearboxes

(1) Both Co Rotating & Counter Rotating types of TB series Twin Screw Gear Reducer are composed by Input & Output elements. Especially for output side which installed by Thrust Bearing plus with flange which could suffer high pressure to absorb the axial pressure caused by the extruders. (2) Following AGMA criterion to design gear elements which adopts low-carbon alloy steel bar materials(Normally, it is SCM420 or same level). The precision reaches AGMA 10 level after carburization heat treatment then treating gear surface grinding to make sure low noise, low abrasion and high efficiency during operation. (3) #294 Series Thrust bearing with axial self-aligning roller type & muti-row stacked tandem bearing package to have advantage of low friction heavy axial load capacity.

Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Horizontal Blow Molding Machines

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome. Co-extrusion application is the advanced technology by the leading brand: Full Shine.

Small Blow Molding Machine

Categories : Electric Blow Molding Machines

Small-Continuous Type Blow Molding Machine This series model can produce small size containers ranging from 20mL to 10L for applications such as cosmetics, beverages, edible oil, pharmaceutical use, chemicals, housewares, and other industrial purposes. With the energy-saving system option, this machine can save up to 20% of power consumption. Some of the most common applications for small blow molding machines are: Lubricant oil bottles Laundry detergent bottles Cosmetic bottles Pesticide bottles Pharmaceutical bottles Multi-color kettles PVC cans Moreover, small blow molding machines can be customized according to the client’s needs of production: It can be a single or double station machine A visible stripe extruder unit can be added to observe liquid level It can include an auto-deflashing unit and many other features to make the machine as automatized as possible. An automatic extrusion blow molding machine is many times preferred because it leads to the reduction of manpower need which results in reduced costs, increased efficiency, and time savings for an organization.