OPP/BOPP Labeling Machine For Square & Round Bottle -Automatic High Speed

Categories : Labeling Machines

1. Application for labeling round and square shape containers. 2. Fully automatic rotary operation for 330ml-4000ml bottles.(with certain change of parts). 3. Machine frame made of stainless steel 304. 4. PLC electronic control, touch screen monitor and electronic speed control(frequency inverter). 5. With a star-wheel carrying containers firmly while dispensing , provide stable dispensing performance under high-speed operation. 6. Use servo motor to synchronously tracks label supply, label cutting and use specially designed vacuum drum to ensure precise labeling. 7. Three-phase PLC and AC variable control with a synchronized tracking and control system to maintain label cutting accuracy in different running speed. 8. Centralized lubrication system for easy maintenance. 9. Detecting in feed situation with sensor, automatically adjust labeling speed according to feeding situation of production line, making production line coherent. 10. System safety device: when malfunctions such as irregular torques and abnormal feeding occur, machine will automatically stop for operation safety and machine durability. 11. Automatic label proofread system controller made in Germany. 12. Automatic speed self adjustment to contact other machine.

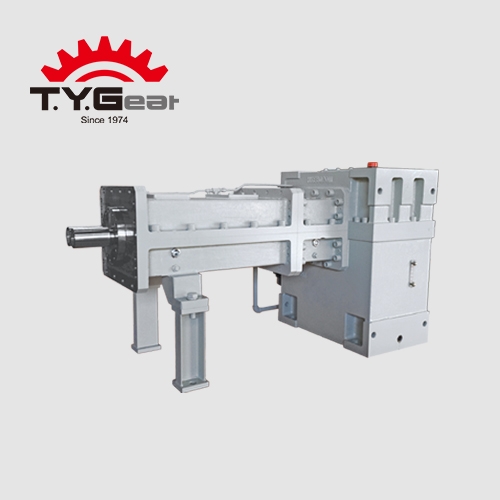

Twin Screw Extruder Co-Rotating Type

Categories : Gearboxes

(1) Both Co Rotating & Counter Rotating types of TB series Twin Screw Gear Reducer are composed by Input & Output elements. Especially for output side which installed by Thrust Bearing plus with flange which could suffer high pressure to absorb the axial pressure caused by the extruders. (2) Following AGMA criterion to design gear elements which adopts low-carbon alloy steel bar materials(Normally, it is SCM420 or same level). The precision reaches AGMA 10 level after carburization heat treatment then treating gear surface grinding to make sure low noise, low abrasion and high efficiency during operation. (3) #294 Series Thrust bearing with axial self-aligning roller type & muti-row stacked tandem bearing package to have advantage of low friction heavy axial load capacity.

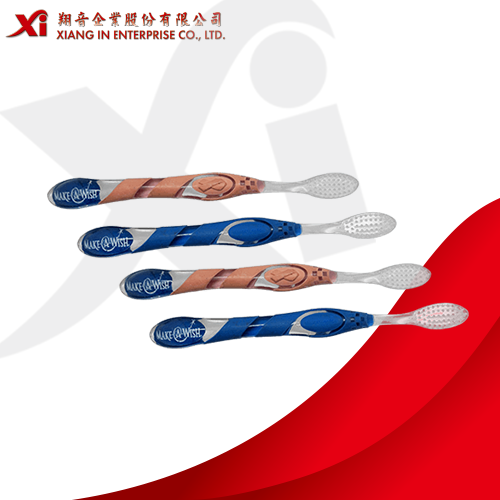

Heat Transfer Film for Toothbrush

Categories : Films

Various Plastic Products, CD Barrel, Container、Metal Outer case、House Ware、Stationer, Gift etc. All kinds of Acrylic plastic products can use heat transfer, as long as the surface is smooth and flat. Look like is transparent is the characteristics of acrylic material, but that make the appearance look monotonous. Now if use heat transfer technology, your design and product can be perfectly combined, and the design can be translucent or opaque, using heat transfer film and heat transfer machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

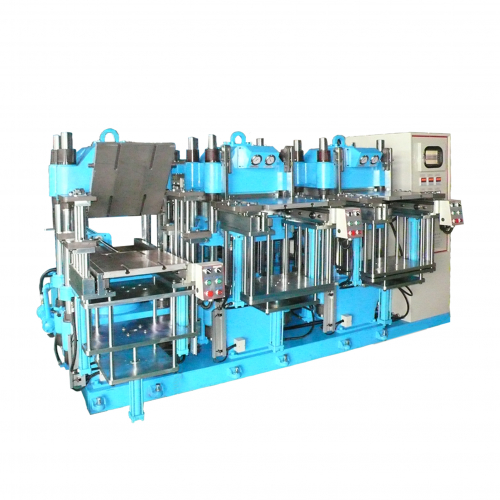

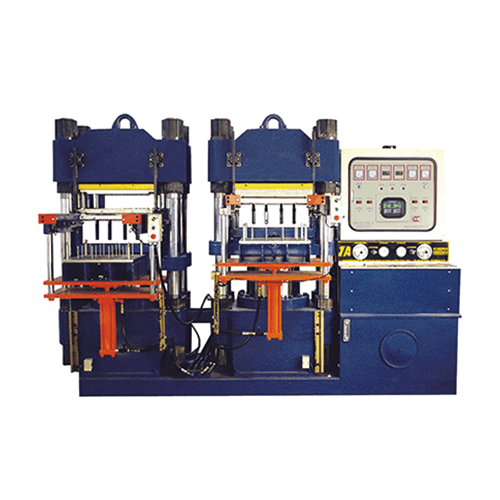

4 Stations 2RT Mold-Open Rubber/Silicone Vacuum Compression Molding Machine /VCC-F2

Categories : Compression Molding Machines

Features This type of machine is multi-functional, because it is suitable to be used for top opening double or triple molds. Dual powers and individual oil system are adopted. Each oil system is designed respectively. It is steady, quiet and low frequency of malfunctions. Two shafts can be operated simultaneous.

3RT Mold-Open + Air-Jig Rubber/Silicone Vacuum Compression Molding Machine / VCC-D3J

Categories : Compression Molding Machines

Features The 4RT surpasses the traditional top opening mold that can be used for taking out the final product when there are triple or four molds with the design of opening mold, pushing out the mold in between, loading the bottom mold, lowering the mold in between, and rising thimble to hit the final production.

2RT Mold-Open Rubber/Silicone Compression Molding Machine / HCC_D2

Categories : Compression Molding Machines

Features This type of machine is multi-functional, because it is suitable to be used for top opening double or triple molds. High force adopts Dual powers and each oil system is designed respectively. It is steady, quiet and low frequency of malfunctions. Two shafts can be operated simultaneous.

Patent Rail Mold-Open Rubber/Silicone Compression Molding Machine / HCC-DP

Categories : Compression Molding Machines

Features This type of machine is suitable to be used for double molds. It is capable of speedy productivity. For the rail mold opening, the opening angle is up to 90 degrees. It is very convenient for operation. High force adopts Dual powers and each oil system is designed respectiv

3 Stations 3RT Mold-Open Rubber/Silicone Compression Molding Machine /HCC-T3

Categories : Compression Molding Machines

Features This type of machine is multi-functional, because it is suitable to be used for top opening triple or four molds. Hydraulic system Designed by proportional pressure and flow ratio, which is steady, quiet and low frequency of malfunction. Two shafts can be operated simultaneously. Slow speed of mold calibration is provided to make the calibration safer and more accurate. Molds can be precisely positioned. A 100% safety design for positioning is available to prevent molds from damage. The speed to open/close the mold is adjustable. It is very accurate and reliable.

Clean Room Vacuum Rubber Compression Molding Machine

Categories : Compression Molding Machines

Specially designed for clean room to make all types of precision rubber products such as aeronautic O-rings, syringe inner pistons and so on.

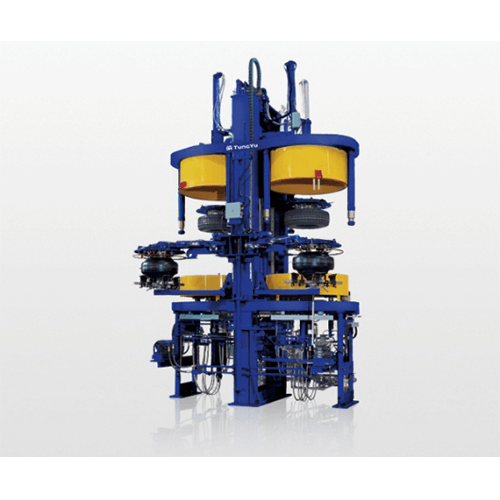

51 Inch Tire Curing Press

Categories : Rubber Curing/Vulcanizing Machines

• Equipped with servo motor for energy saving, product quality stabilization and operation efficiency. • Accurate loader and unloader mechanism with bumper function for excellent alignment. • Heating platen with special channel design for temperature uniform distribution to have the best tire quality. • Rear pneumatic inflator (option): Equipped at the rear side of the mainframe to operate in automation. After the curing process the inflation tire will be cooling and forming to prevent the body from deformation and make sure quality.

Tire Valve Rubber/Silicon Compression Molding Machine

Categories : Compression Molding Machines

Type 300 tons Horse power 10 Hpx2 Stroke 300 mm Working bench 600x600 mm Designed for tire valves, high yield and efficient. Nature rubber Rubber of metal bonded parts Oil-resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber tyre valve

Rear Transfer Injection Type Rubber Compression Molding Machine

Categories : Compression Molding Machines

Special for nylon cord retread tire with high temperature or second curing for tire with low temperature. With loading and unloading platform to save labor handling.