Classification : HOT RUNNER SYSTEMS

Country: Taiwan

Phone: 886-2-29997193

Fax: 886-2-29993403

Contact Person: Anny

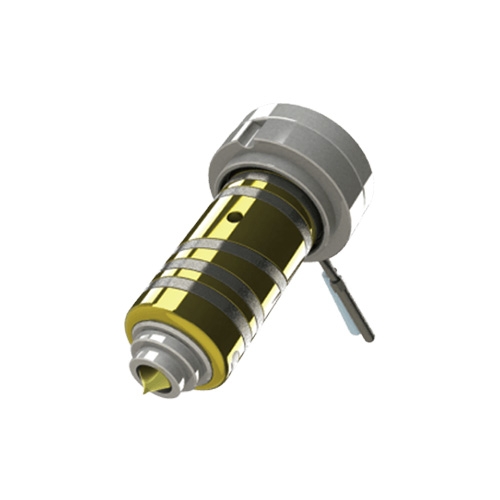

- The most used nozzle.

- There is a torpedo inside the nozzle to have a circularity gate and guide the melt along the torpedo to flow into the cavity, and therefore can reduce the production of cool plug.

- Can reduce the cycle time due to the gate will cool down fast. It will be possible to have 4 seconds / cycle with excellent mold design.

- This series is very popular for unapparent gate mark.

- When the melt has added with glass fiber or is shear-sensitive and has strict requirement to the flow mark that will need more attention.

- Simple and easy to use.

- According to the necessary, we can choose by using Sprue gating or Pin-point gating nozzle.

- The sprue nozzle is the most popular type. Not only it's suitable for almost all of the plastic material but also it provides easy color change.

- The pin-point gating nozzle: It provides good gate mark, reduction in raw materials consumption, and reduction of finishing work on molding.

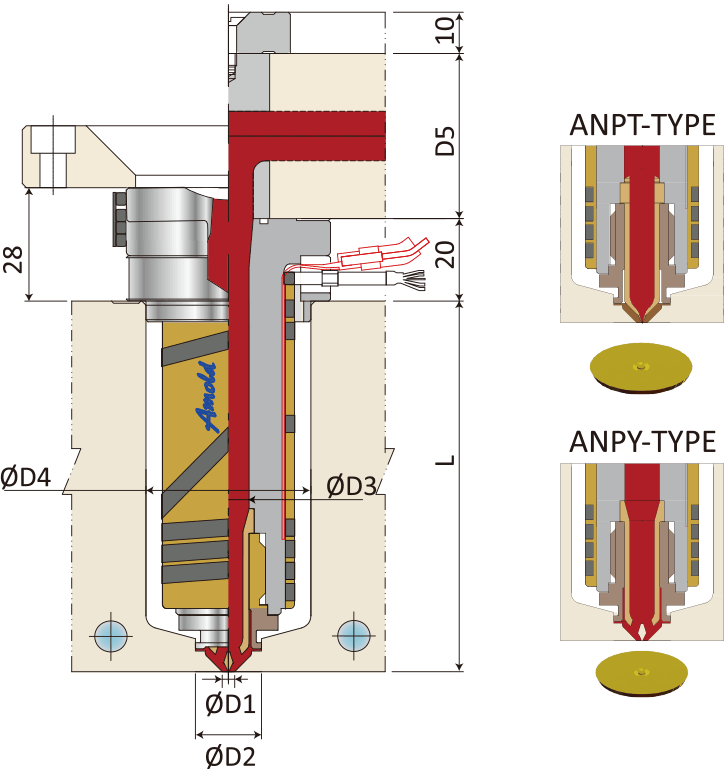

- There are AESB, ANPR, ANPT, NL-ANPT and other specifications.

| Type | ANPT 10 | ANPT 20 | ANPT 30 | ANPT 40 | ANPT 50 |

| Ø D1 | 0.8~1.2 | 1.0~2.5 | 1.5~3.0 | 1.8~3.5 | 3.0~4.0 |

| Ø D2 | 8 | 9 | 15 | 16 | 20 |

| Ø D3 | 4 | 5 | 7.5 | 10 | 14 |

| Ø D4 | 19 | 25 | 32 | 40 | 45 |

| D5 | 40 | 40 | 40 | 40 | 45 |

| L | 55~95 | 52~160 | 80~250 | 80~400 | 80~600 |