Plastic Recycling Machinery

HOT NEWS

Cost-Saving and Friendly Operation POLYSTAR Plastic Recycling Machines

Plastic pelletizers are not only used by recyclers anymore as more producers now adopt circular economy standards in their factories. Having a recycling machine in your production facility not only helps the environment but can also help you cut costs. Before choosing a recycling machine you must consider some important factors, that you will find in this article.

Quality and Consistent Output with POLYSTAR Recycling Machines

Recyclates with proper pre-works and a recycling process with careful inspections will bring you high-quality plastic pellets which meet the market standards. POLYSTAR aims to help you identify any crucial missing elements in your plastic recycling process and provide suggestions to improve your recycling business.

Unlocking the Process: How to Establish Your Own Plastic Film Recycling Washing Line/Plant in 5 Steps?

In the last decade, Plastic Film Recycling Washing Line has become a popular option for companies looking to reduce their carbon footprint and increase their sustainability. The process of building your own plastic film recycling washing line can seem daunting, but it doesn't have to be. With careful consideration of various factors, you can unlock the process to establish your own plastic film recycling washing line/plant.

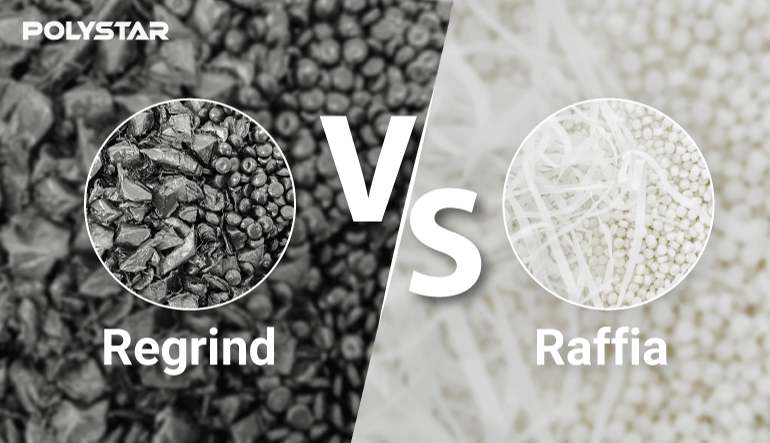

Choosing the Right Recycling Machine: Hard Plastic Regrind VS. PP Raffia/Woven Recycling

There are plenty of plastic material types that we use in daily life as well as in many different industries. In addition to different polymer types of them, these plastic materials also come in different shapes, sizes, textures, and levels of stiffness. These are the main points that plastic recycling machines should specialize to process certain types of plastics more efficiently while still capable to process various types of other plastic materials.

What is Post-Consumer Plastic Recycling? - Advantages and Solutions

Plastic is one of the most widely used materials worldwide, found in everything from food packaging to car parts. As a result, the amount of plastic waste produced is enormous, creating an environmental problem. This is where mechanical recycling has become a popular solution among plastic producers and recyclers.

BoReTech: PCR Plastic Recycling Process From BoReTech

PCR (Post-Consumer Recycled) plastics are made from plastic waste that has been collected from consumer products and recycled. These plastics are mainly derived from PET bottles, HDPE bottles, and LDPE films. For food-grade waste plastic recycling, PET bottle recycling is a major development trend in the waste plastic recycling industry. The process of recycling and washing PCR plastics involves several steps, including washing, grinding, pelletizing, and SSP (Solid State Polymerization) to produce food-grade recycled flakes and pellets that meet FDA or EFSA certification.

FIMIC: Filtration Technology for PET Recycling

Polyethylene Terephthalate or simply PET, is one of the most recyclable plastics, widely used world-wide in many different applications. Light, strong, durable and safe, PET offers a number of advantages being almost uniquely among plastics. Because of PET's incredible performance and recyclability it is one of the most sustainable packaging materials. It is in fact approved as safe for use in direct food contact all over EU, as well as many other Countries, both in virgin or recycled form.

Benefits of Recycling Plastic Film and Bag Production Wastes In-house

Due to the large size of productions of 15 years old fast-growing bag manufacturer for many different companies, the scraps generated from plastic flexible packages, patch and soft handle bags, punched-out handle bags, courier bags, exam bags, gift packages, shrink films and document pouches were considered as high. The bag producer needed to work with several professional recyclers to reprocess them.