High Precision Injection Mold

Categories : Injection Molds

-Design & Development of Diversified Precise Molds -Mold flow analysis & optimized solution for mold design -Specialized molding system: Sale & Integration (PET/IML/Medical series) -Turnkey Solution Planning & Technology Transferring (operators’ training included)

IML Moulds

Categories : Injection Molds

Mold size: cover-410 x 400 x 380 mm Mold weight: 450kg Injection machine: 260Ton Surface: In mold label

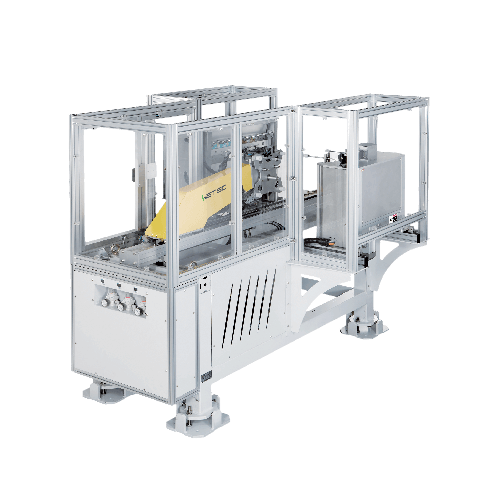

Label Converting Machines and Label Finishing Machines

Categories : Cutting Machines

Applications: IML(in mold label), Self-adhesive Label, Sticker, Foam, IPO, Single/Double sided adhesive, Post-press finishing material…etc yicheen

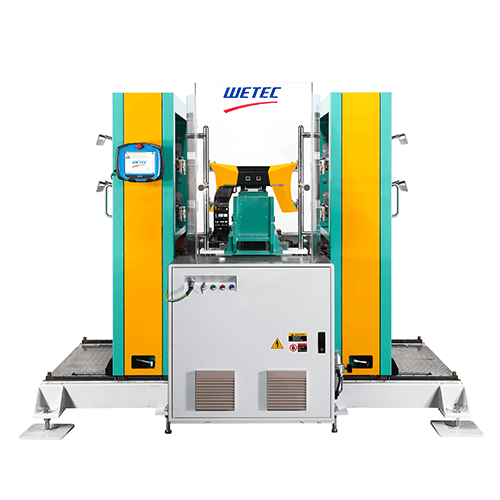

Continuous Extrusion Blow Molding Machine with In Mold Labeling

Categories : Horizontal Blow Molding Machines

This series is a single station extrusion blow molding machine for containers from 50ml to 20L. These machines exhibit high reliability, excellent efficiency and flexibility to meet varied customer requirements.

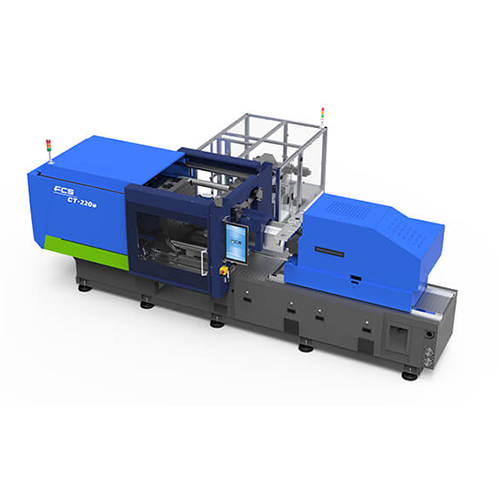

In Mold Labeling Turnkey Solution

Categories : In Mold Labeling Injection Molding Machines

In Mold Labeling (IML) is a high-efficient technique. By placing the printed label in the mold before injection and bonding the label with the plastic products during injection process, lML can produce high-quality products efficiently, cost-effectively and also environmentally friendly.

650T-6000T Injection Molding Robotic Arms - Titan Series

Categories : Industrial Robots

The Titan series of robotic arms are used for various types of large plastic horizontal injection molding machines of 650-6000 tons. There are 3-axis and 5-axis AC servo drives. The vertical arm is telescopic stage, runner arm can be added to take out the runner. Redstone series is also a kind of top entry IML robot that is able to place the labels inside the mold and take out the finished products precisely. It is different from the side entry IML robot, the robotic arm goes into the mould from the top, which would not require much space around the machine.

In Mold Label (IML Label)

Categories : IML

In-Mold label (IML) is widely used in food container because the ink is between two layers of film and normally produce in dust-free fab or air conditioning clean room to minimize the human touch. Using IML can do the injection and labeling the product at the time. So it is suitable for mass production and standardization.

Extrusion Blow Molding Machine PK-CS/CD/CS3/CS4/CS8/CS12

Categories : Extrusion Blow Molding Machines

Single Station Single/Double/Triple/Quadruple..12 Head Horizontal Operated Clamping System Production Volume:2ml~35L Multi layers: Co-Extrusion 1-6 Layers Multi cavities: 1~12 cavities Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion material Special function:View Stripe Clamping system:Toggle/3 Tie Bar/4 Tie Bar Driven Model: Hybrid servo motor drive system/ High performace hydraluic power saving system/Close loop proportional valve Support Parison controller/Auto Deflasing/Auto Recycling/Auto material feeder/Remote trouble shooting funciton/IML

Total Solution For In Mold Decoration Technology

Categories : In Mold Labeling Injection Molding Machines

• Total Solution For In Mold Decoration Technology. • Environment-friendly plastic decoration process - IMD/FIM/IML. (In-Mold Decoration / Film Insert Molding / In-Mold Labeling) • Product: Housing/casing of mobile phone, mp3/mp4, GPS, Lab-Tab Computer, 3D Labeling of Electric Goods;Automotive Dashboard Meters, Controllers, and Interior Decorative Items; the fancy colored Plastic Body Parts of Motorbike,...etc.

In-Mold Label

Categories : Films

In-Mold label (IML) is widely used in food container because the ink is between two layers of film and normally produce in dust-free fab or air conditioning clean room to minimize the human touch. Using IML can do the injection and labeling the product at the time. So it is suitable for mass production and standardization.

All Electric / Hybrid Extrusion Blow Molding PK-e / Hybrid Series

Categories : Extrusion Blow Molding Machines

Single/Double Station Single/Double/Triple/Quadruple..8 Head Production volume:2ml~35L Multi layers: Co-Extrusion 1-6 layers Multi cavities: 1~8 cavities Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion material Special function:View stripe Clamping system:Ultra locking system/Toggle/Tie bar Driven model: Precision servo gearmotor/Hybrid servo motor drive system/High performance hydraulic power saving system/ close loop proportional valve Support full electric/Full hydraulic parison controller/Auto deflashing/Atuo recycling/Auto material feeder/Remote trouble shooting function/IML