Large Horizontal Rotary Table Two-Component Injection Molding Machine (HB-R Series)

Categories : Horizontal Injection Molding Machines

It is a large injection molding machine, which is suitable for large-scale home appliances and panels, automotive skylights, lights,

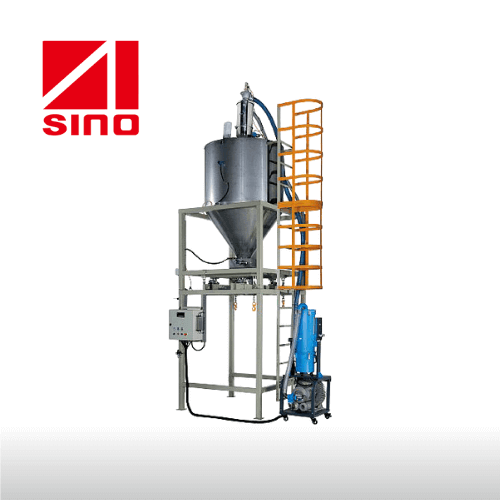

Automatic Batch Weighing and Mixing System

Categories : Dosing and Measuring Equipment

Automatically measuring equipment for efficient mix and material processing. Equip with auto conveying system, batching system, mixer, kneader, extruder and steel construction plant. Discharge feeder: scale screw feeder Automatically conveys material to extruder after mixing PC control monitoring system live network Complete installation of pulverizer series

Hopper Dryers - SHD-U

Categories : Dryers and Dehumidifiers For Plastic Materials

SHD-U hopper dryer can efficiently dry most of standard hygroscopic plastics as to ensure high quality molding products. The concise structure makes it easy to mount on the IMM, and the drying hopper can also be directly mounted on the floor with the floor stand. Besides, there are multiple optional accessories to meet different production demands, such as hot air recycler, magnetic base and maintenance ladder etc.

PET Stretch Blow Molding Machine for up to 1500ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower.

Two Platen Injection Molding Machine (LM Series)

Categories : Injection Molding Machines by Platen

It is medium and large scale injection molding machine. It is applicable to automotive industry such as bumper and

PET Stretch Blow Molding Machine for Wide Mouth / Large Containers

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET large volume bottles, oval bottles, flat bottles and jars with volumes up to approximately 6000ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Suitable for clean lotion, edible oil, detergent, pickle food, etc. Small & Medium Volume Bottles

PET Stretch Blow Molding Machine for up to 600ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower.

Mold Temperature Controller (YBMI/YBMD)

Categories : Control Equipment

Steady controlled temperature makes plastic molding accurate in size and consistent with quality. Accurate mold temperature solves the problem of plastic flow patterns, reducing flow and weld lines, gloss appearance, record grooves effect, silver streaking, stress-whitening, warping, and etc.... P.I.D temperature controllers are used for accurate control of temperature within±1℃. Two-step-heating selector makes rapid temperature increasing possible when require thus saving time and power specially start up in the morning. Patented “Heat-insulated” design improves your safety, extend the machine’s lifetime and make maintenance more efficiently. YBMI : By oil, suit for long-term continuous operation, keep the temperature steady, no flash on tiny and thin products, and no corrosion. However, the heater may be damaged if you do not use the thermo oil correctly or change oil routinely. Recommend to choose oil-type mold temperature controller when your required temperature is 150℃ or above. YBMD : By water, heating up faster, cooling better, harmless to your mold and more economic than oil type for maintenance and cost. However, the water boiling point is low and the element of different water may occur corrosion or limescale to affect the heat exchange and products quality. Recommend to choose water-type mold temperature controller when your required temperature is 150℃ or below.

Electronic Analytical Balance Scale

Categories : Dosing and Measuring Equipment

The DT analytical balances accurately measures the weight(denier) of PP/HDPE flat yarn.

High Performance Pressure Transducers

Categories : Indicators and Sensors

ll Scale Pressure Range 0-100 thru 0-100K PSIS (0-6.89 thru 0-6894 bar) Accuracy (RSS) (BFSL Non-Linearity, Hysteresis, Non-Repeatability) 0-300 PSI thru 0-15K PSI Ranges±0.20% FSO ( ±0.15% FSO improved with "DN" option) < 0-300 PSI or > 0-15K PSI Ranges±0.25% FSO ( ±0.15% FSO improved with "DN" option) Linearity (Best Fit Straight Line) 0-300 PSI thru 0-15K PSI Ranges±0.10% FSO (BFSL), Typical < 0-300 PSI or > 0-15K PSI Ranges±0.15% FSO (BFSL), Typical Hysteresis < ± 0.05% FSO, Typical Repeatability < ± 0.05% FSO, Typical Full Scale Output (FSO) 16 mA Zero and Span Balance ±1% FSO Long Term Stability ≤±0.25% FSO per 6 months Response Time <2 mSec to reach 90% FSO Temperature Effect on Zero ≤±1% FSO per 100°F (37°C) Temperature Effect on Span ≤±1% FSO per 100°F (37°C) Compensated Temperature 70°F to 170°F (21°C to 76°C) Operating Temperature -40°F to 190°F (-40°C to 87°C) Storage Temperature Limit -65°F to 250°F (-53°C to 121°C)

Plastic Machine Controllers - AR Series

Categories : Industrial Software

The integrated innovative wise technology with reliable Distributed Control System contains higher performance. Software combined with State-of-art window screen to provide smart and instinct object-oriented editing style hybrid switching with simple and popular PLC ladder program editor. His high-speed Ethernet communication network link-up between Humanity Interface and remote devices to displaying the future one-stop control advantages! It can be broadly applied to automated machinery control, such as injection molding extruder machine controllers and equipment. Arico

Storage Tank with Blowing-PSP

The PSP series storage tank with optional blower is Sino-Alloy’s solution for the temporary storage of the rubber or plastic pellets before packaging. The PSP series storage tank is made of stainless steel and can be customized to the customer’s specifications. The optional blower/dryer can help ensure there is no buildup of residual moisture. An optional vacuum loader can transport the rubber or plastic pellets from the PSN separator directly to the PSP storage tank. Also available with a packaging function includes air control valves to regulate the output quantity and an automatic weight scale.