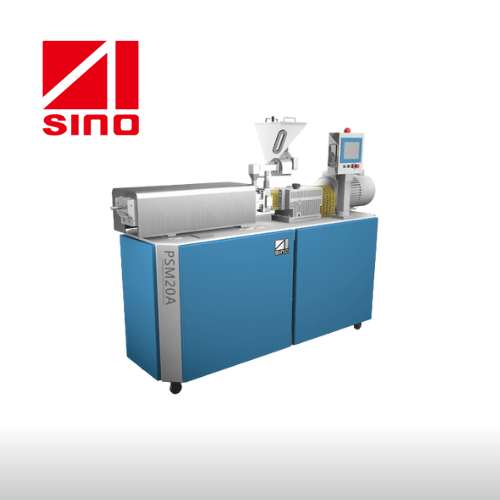

Clam-Shell Design Co-Rotating Twin Screw Extruder-PSM20A

Categories : Granulators

The PSM20A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

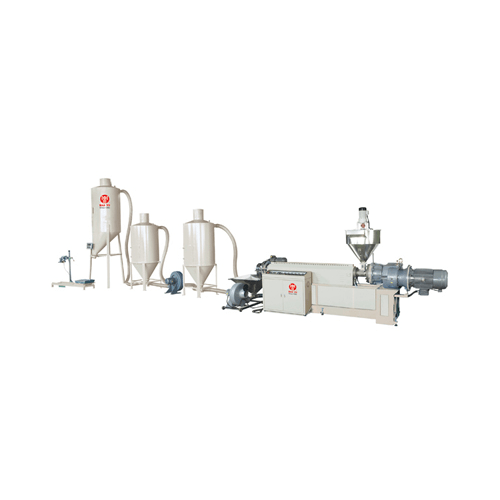

Plastic Pelletizing Machine / Pelletizer Extrusion Line

Categories : Plastic Pelletizer Machines

Optional Accessories:(1) Wood flour drier(2) Humidity tester(3) Chiller(4) Water cooling tower(5) Movable electronic balance with portable sewing machine (6) Wood flour grinder

Repet Wood WPC Granule Pelletizer Plant

Categories : Plastic Pelletizer Machines

Indoor & outdoor building material Outdoor furniture

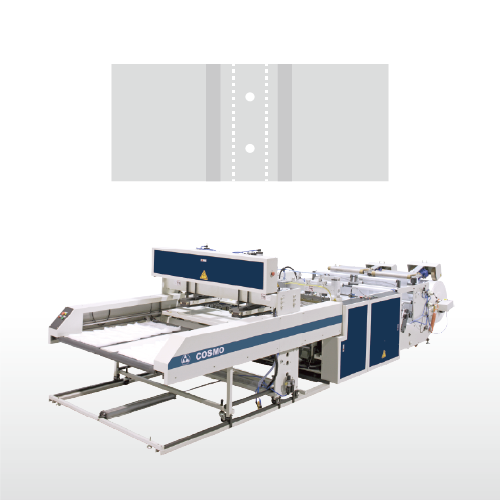

Fully Automatic High Speed 2 Lines Saddle Bag & Wicket Bag Making Machine-SSD-600 / SSD-1000

Categories : Plastic Bag Making Machines

Computer control over the entire process From film roll to final pruduct, one process flow Automatically stop when running out of film / film feeding blocks or jam High-productivity performace saves time and labor

Volumetric Dosers - SCM

Categories : Dosing and Measuring Equipment

SCM series volumetric doser is suitable for even feeding of masterbatch, additive, and virgin material to the plastic process machine. The unit has a selection of four dosing screw sizes for different throughput needs. The unit can supports up to four sets of dosing screws for various material receipt. In SCM-D with three components application, two material dosed via a screw unit and free flow of main material through neckpiece. In SCM-4 with five components application, four materials can be dosed via a screw unit and free flow of main material through neckpiece. SCM in high drying temperature application, such as PET preform production. Water cooling kit should be added to prevent masterbatch from sticking in the screw. Add "H' at the end of the model code. SCM syncronize dosing speed in extruder mode via analog 0~10V input from the extruder. Combination of Shini VL venturi loader realizes auto conveying of material to SCM at all time.

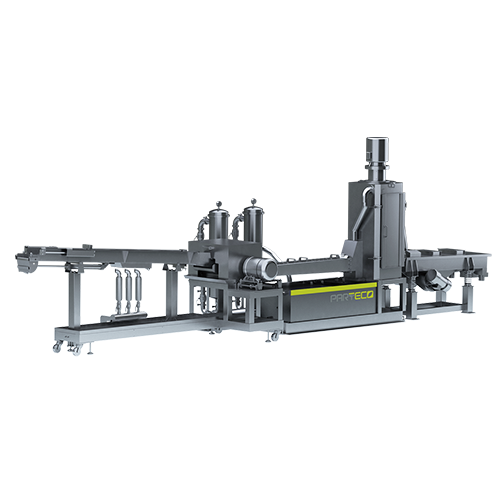

Granulating System: Flow Channel of Plastic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

The plastic strand pelletizing system consists of a die, water-cooling channel, pelletizer, centrifugal hydroextractor and a circulating water-cooling system. Mainly used for plastic materials such as PET、PA、PC etc

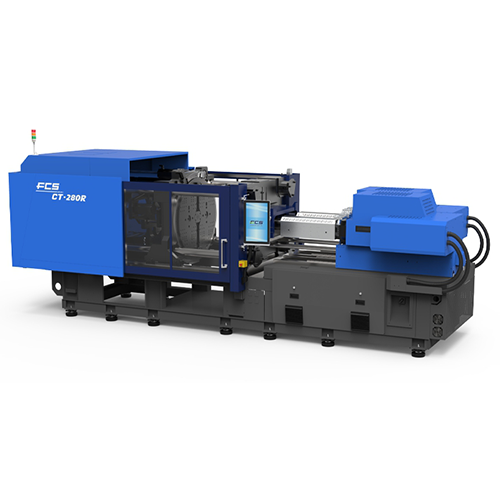

All-Electric Two-Component Injection Molding Machine (CT-R series)

Categories : Electrical Injection Molding Machines

It is All-Electric Two-Component injection molding equipment. It is suitable for two-component and multi-component products, including electronic parts, medical appliance, cosmetic containers, etc.

Rotary Shaft Two-Component Injection Molding Machine (FB-T Series)

Categories : Horizontal Injection Molding Machines

The rotary shaft two-component injection molding equipment, which is suitable for two-component products covering the penetration, including tool handles, buttons, handles and other products.

Large Horizontal Rotary Table Two-Component Injection Molding Machine (HB-R Series)

Categories : Horizontal Injection Molding Machines

It is a large injection molding machine, which is suitable for large-scale home appliances and panels, automotive skylights, lights,

Twin Shaft Shredder (Kroko Twin Series)

Categories : Plastic Shredders

Intelligent control system The program system monitoring the shredding status and allows automatically reverse and forward motion to keep most stability while creating best production. High radial loads with high efficiency and great stability The professionally designed shaft and blades are made with high wear-resistant steel and processed by heat-treatment to increase the service life. It can withstand higher radial load and create higher efficiency while keep the best stability.

Twin Shaft Shredder

Categories : Plastic Shredders

Design especially for bulky plastic products. Eliminate the disadvantage of traditional high horse power crusher. Also for cracking unusual objects, waste tyres, logs, sleepers, etc. High capacity; low noise; installing easy replaced screen makes the desired output size available The knife is detachable, mutiple used and can minimise the wear and tear cost Easy operation Particle in uniform size Customized size is accepatable

Surface Winding Slitting Machine Series-FSL-BT

Categories : Slitters and Rewinders

Design for slitting thin and slip plastic films of uniform thickness such as laminating paper, aluminum foil, stretch film, isolated film, sticker and other film rolls. The most smooth edge after slit is ensure by the surface wind method.