Blow Molding Machine PBS 905 Series

Categories : Electric Blow Molding Machines

Powerful, crank type mold clamping system combined with German linear guides for maximum stability. This series is ideal for producing medium and large sized containers.

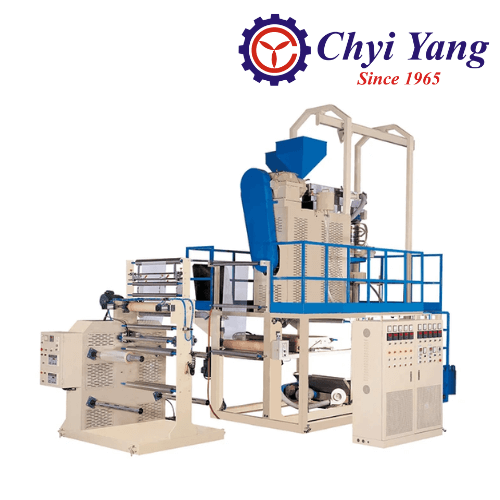

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine, CHYI YANG is Multilayer Co-Extrusion Manufacturer, We mainly produce plastic film machinery whole plant equipment and inseparably linked with the life and development of plastic machinery in Taiwan.

Blow Molding Machine Multi Layer Series

Categories : Electric Blow Molding Machines

VS series: suitable for visistripe bottles (ex. Motor oil bottle) -TC series: for the production of two-color plastic containers or toys -TL series: suitable for 2-layer bottles (ex. Cosmetic bottle only outside layer with pearl or color & made of virgin material) -Double-head or 3-layer machine can be delivered to order

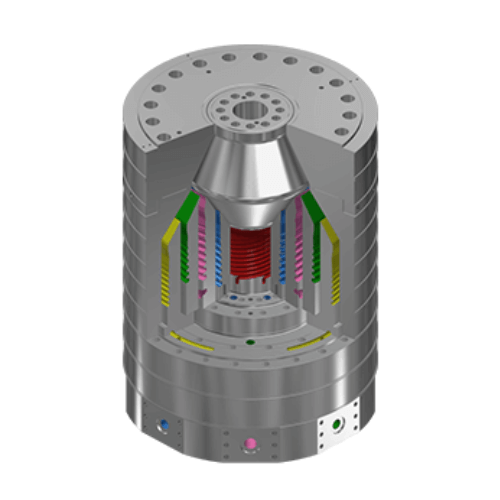

ABA Double Die Head

Categories : Extrusion Dies / Dies Heads

The Blown Film Die Head is the core component which is called the ‘‘heart’’ of the Plastic Film Blowing Machine. The main function of Die Head is to distribute the melted polymer evenly so that the thickness measured around the circumference of the tube being produced is uniform. It is the key factor to ensure a quality film. A well-designed Blown Film Die make the molten polymer travel through the Die Head smoothly without any of the polymer staying inside. A good quality melt means it does not have flow die lines on the surface which could result in defects on the film. A good Blown Film Die Head design incorporates properly constructed flow channels to allow the molten film to flow with the average speed around the circumference. Co-Extrusion Dies are another type of design allowing for speedy production of multilayered films. Co-Extrusion Dies are often used to change the structure of the layers to match the characteristic of polymers. The difference polymers affect the design of Die Head, as well. This also requires Die Head to have a short residence time. Further, the purge or change-over times are not excessive when switching from one polymer to another. HSIN LONG

5 Layer Die Head

Categories : Extrusion Dies / Dies Heads

The Blown Film Die Head is the core component which is called the ‘‘heart’’ of the Plastic Film Blowing Machine. The main function of Die Head is to distribute the melted polymer evenly so that the thickness measured around the circumference of the tube being produced is uniform. It is the key factor to ensure a quality film. A well-designed Blown Film Die make the molten polymer travel through the Die Head smoothly without any of the polymer staying inside. A good quality melt means it does not have flow die lines on the surface which could result in defects on the film. A good Blown Film Die Head design incorporates properly constructed flow channels to allow the molten film to flow with the average speed around the circumference. Co-Extrusion Dies are another type of design allowing for speedy production of multilayered films. Co-Extrusion Dies are often used to change the structure of the layers to match the characteristic of polymers. The difference polymers affect the design of Die Head, as well. This also requires Die Head to have a short residence time. Further, the purge or change-over times are not excessive when switching from one polymer to another. HSIN LONG

Stacked & Multilayer Type Die Heads

Categories : Extrusion Dies / Dies Heads

+For all kinds of blown film machines and it is suitable for multi-layer products. +The stacked design provides high stability & good quality.

PP BLOWN FILM MACHINE

Categories : Blown Film Extruders

High Speed PP Blown Film Machine is suitable for producing PP bags and films. Special design of screw results in better mixing to ensure high output and good film quality. AC inverter control motor for energy saving. The water-quenched system effectively makes films glossier and more transparent, very suitable for food, flower and garment packaging. Also capable of producing multilayer films (Model: CTPP)

Multilayer Blown Film Line(JC-CX Series)

Categories : Co-Extrusion Blown Film Machines

The JC-CX series Multi-layer Blown Film Line is available in two layer, three layer, and up to five layer configuration based on a modular concept producing variety of quality film over various industries. Combines high output with excellent film quality, the line is designed to produce films for a wide range of application. From general purpose packing film or lamination film, of complex technical film or food packaging with high grade barrier properties, JC-CX series blown film line has convincing solution to every customer’s need.