Blow Molding Machine PBI-X Series

Categories : Extrusion Blow Molding Machines

This series of machine is equipped with a standard accumulator head. Especially ideal for producing picnic tables, tool boxes, toys, automotive duct, L-ring drums and stacking chemical drums up to 220 liters.

Blow Molding Machine PBS 905 Series

Categories : Electric Blow Molding Machines

Powerful, crank type mold clamping system combined with German linear guides for maximum stability. This series is ideal for producing medium and large sized containers.

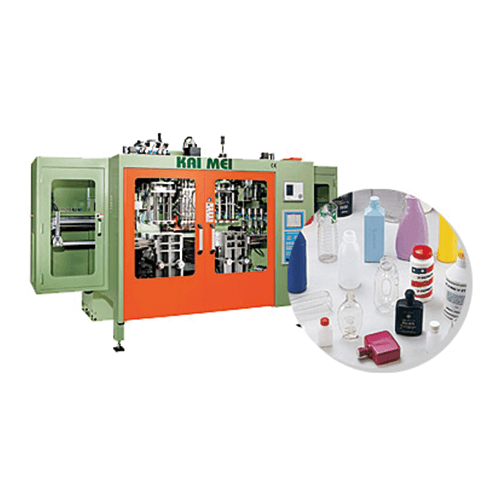

Blow Molding Machine PBSS SERIES 605 / 705 (S / D / T / Q)

Categories : Injection Blow Molding Machines

Double Stations Series Double station machine, full automatically, suitable for producing high-production runs of medium size bottles, ex. Cosmetic bottles detergents, etc. Mold-platen moves properly with high stability and high efficiency Three tie-bar horizontal traveling mold carriage combined with German linear motion guides for outstanding performance and high efficiency. This series is designed to meet high production and small size container requirements. Available to equip with auto de-flashing device and take out robot to achieve fully automatic and highly efficient production. 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, convenient and user-friendly operation.

Blow Molding Machine PBSS SERIES - 905 / 1005 (S / D / T / Q)

Categories : Horizontal Blow Molding Machines

Powerful, crank-type mold clamping system combined with German linear motion guides for outstanding performance and high efficiency. This series is designed to meet high production requirements. Available to equip with auto deflashing device and take-out robot to achieve fully automatic, highly efficient production. 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, maximum operational convenience and user-friendly operation.

Blow Molding Machine PBSS - 905 O/1005 O

Categories : Electric Blow Molding Machines

It is designed for small containers Mouth-to-Mouth design. Mouth-to-Mouth design can improve two-time production for double-station machines. It creates a unique and new mold design and auto cutting device. It can increase machine stability and decrease defective rates. This is the latest high-producion machine technology.

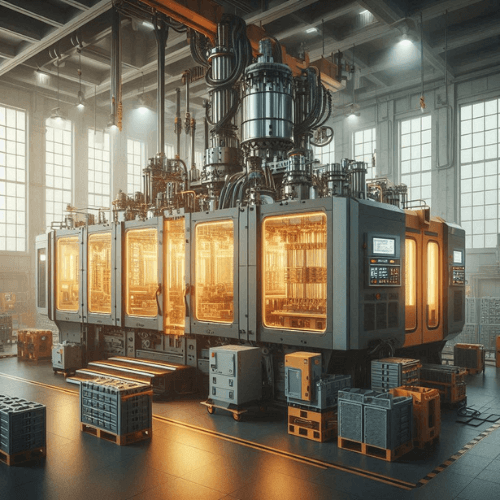

85-150 ton injection molding machine product

Categories : Injection Molded Products

This 85-150 ton injection molding machine is designed for high-precision plastic product manufacturing, including automotive components, electronic parts, appliance housings, medical devices, and consumer goods. Equipped with a high-efficiency servo-driven system, it ensures stable injection pressure and precise control, delivering superior molding quality. With a high-rigidity clamping structure and an optimized hydraulic system, this machine offers durability and operational efficiency. It supports various plastic materials (PP, PE, ABS, PC, PA, etc.) and can be customized with multi-stage injection units and robotic interfaces for full automation, reducing labor costs and increasing productivity. Ideal for OEM manufacturers, plastic molding factories, and precision molding industries, this model meets modern production demands with efficiency and precision.

Fully Automated Production System

Categories : Loading and Conveying Machines

Fully Automated Production System

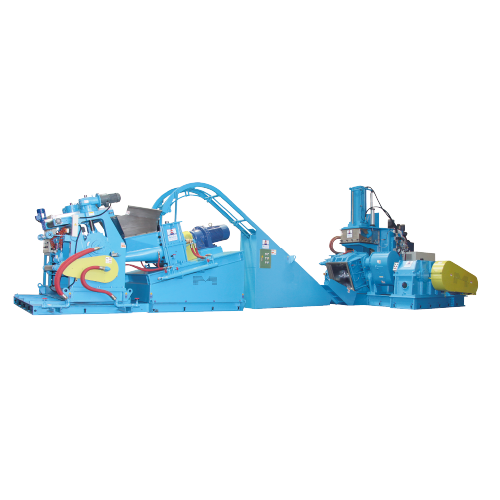

TPE Automatic compounding Line (Under Water Cutting)

Categories : Plastic Pelletizer Machines

1. SBS 2. SEBS 3. OVERMOLDING (For PP, PE, PS, PMMA, PETg, ABS, PC, PA) 4. TPV 5. TPU (Hotmelt Adhesive) 6. TPEE

WPC - Fully Automated Production System For Wood Plastic Composite

Categories : Plastic Pelletizer Machines

WPC PROCESS FLOW: . NATURAL RECYCLED WOOD . WOOD POWDER . WOOD PLASTIC COMPOSITE . WPC PRODUCTS

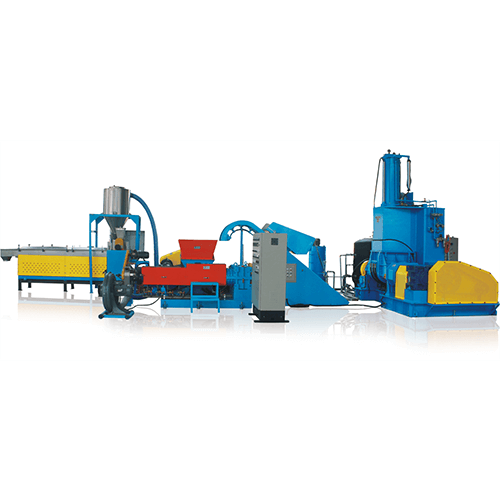

Rubber Accelerator or Additive Compound Pellets Making Line

Categories : Plastic Pelletizer Machines

JKH doesn’t just deal in plastic processing. We can also pelletize rubber and many other different types of materials. The JKH Rubber/Additive Compound Pellet Making Line is the machine to meet all of your rubber/composite pelletizing demands. We can also provide automated production line for you, and to adjust and customize equipment according to your needs.

Skip Conveyor

Categories : Loading and Conveying Machines

Skip Conveyor For Various Automation Production Line To Design Match, Between Machine To Carry Compound Process.

Double Toggle Injection Molding Machine (SMV Series)

Categories : Horizontal Injection Molding Machines

• Double cylinder design reduces injection unit distance. • Ion nitrided essential components-barrel,screw etc. ensure lasting life. • Easy-adjustable and reliable Multi steps injection pressure and speedcontrol. • Steel bushes have a hardness of HV800 for wear resistances. • Auto-lubrication system is provided to assure the constant lubrication of the toggle mechanism • Multi-stroke hydraulic ejector ensures positive ejection of the product and enables unmanned production with or without the use of a robotic arm. • Differential hydraulic circuit shortens cycle time and saves energy. • Low pressure mold protection system was used to avoid mold damage or excessive wear.