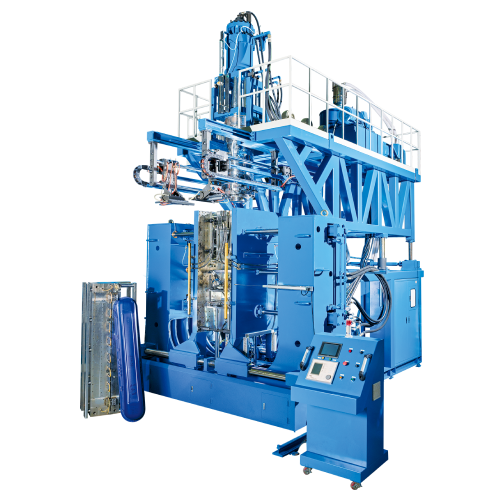

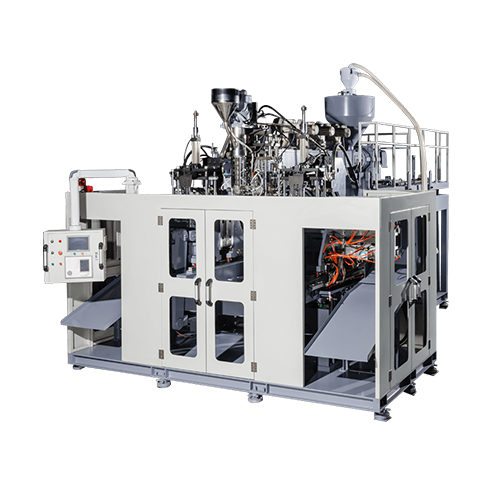

Large Blow Molding Machine

Categories : Horizontal Blow Molding Machines

Large –Accumulator Die Head Type Blow Molding Machine These series models are suitable for productions ranging from 30L up to 130L whether for barrels, pallets, toys, water storage tanks, floats, automobile parts, and narrow or full open mouth drums applications. This machine is suitable for blowing irregular-shaped plastic products. Applications of a large accumulator blow molding machine include the following: Barrels 2-mouth jerry cans Toys Water storage tanks/ PC water jugs Paddle wheel aerator floats Air duct and other automobile parts Baby safety seats Cooler box/ice bucket Sports equipment Narrow mouth and full open mouth drums For certain products, we have developed a high-speed model of this series for customers that need a high production output.

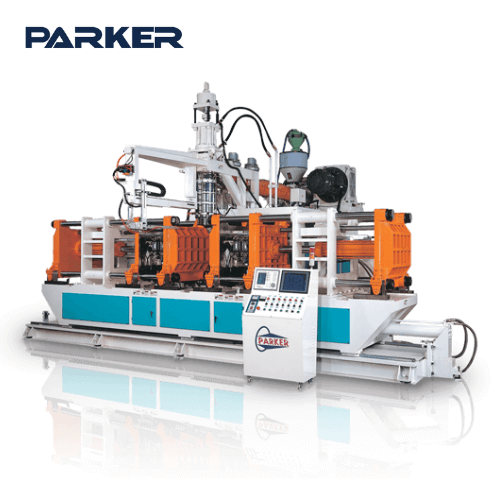

Double L-Ring Drum Blow Molding Machine

Categories : Horizontal Blow Molding Machines

Double L-Ring Drum Blow Molding Machine Double L-ring drums are very popular for the storage of dangerous liquids for the chemical industry. They are made of HMW HDPE, which has antiacid, alkali, and impact resistance characteristics in order to adapt to different conditions and climates. This advanced plastic drum making machine assures a perfect L shape and has a special cooling process for drum strengthening. Moreover, we make three times complete drop tests from a height of 1.5m by the front (neck part), body, and angle to ensure quality. In this machine, you are looking for unbeatable performance in every aspect. These machines are suitable for containers up to 250L.

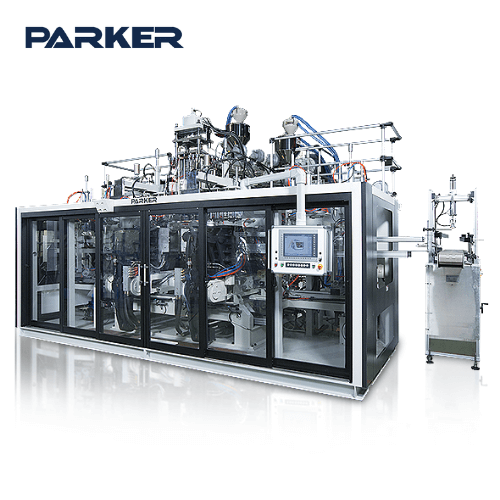

Medium Co-extrusion Blow Molding Machine

Categories : Electric Blow Molding Machines

Chen Way machinery is well-known for its 20L three layers blow molding machine. The recycle resins and the calcium carbonate (CaCO3) in the middle layer help to save material cost. Three layers M/C is the most popular choice for the edible oil export countries, production ranges from 5L to 30L jerry can. The outer and inner layer composed of 15%-20% virgin material and master batches. The middle layer can put around 60%-70% cost effective regrind material and also can add CaCo3 (no more than 30%), which can reduce cost down to 10-12% material cost. By contrast, the single layer jerry can only add around 5%-7% CaCo3 which has no evident improvement over material savings. Chen Way CWM

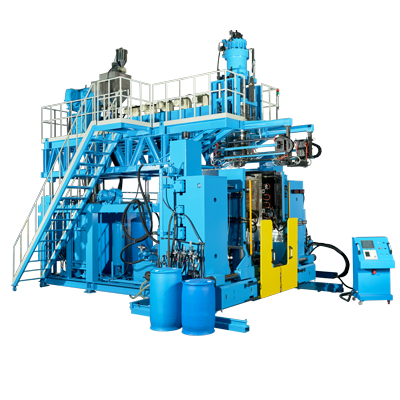

Medium Blow Molding Machine - Double Station

Categories : Electric Blow Molding Machines

Medium-Continuous Type Blow Molding Machine An all-rounder that is ideal for a variety of applications. Medium blow molding machines are used to produce medium-sized products but can also be adapted for small or large-scale productions. Products that are commonly manufactured by medium continuous blow molding machines include: 20/25L jerry cans 10/20L inner thread jerry cans Diamond-shaped jerry cans Round jerry cans Water tanks With applications for edible oil, lubrication oil, electronic, agriculture, and chemical liquids, this jerry can making machine is also available as a single or double station machine, for multi-layers, multi-cavities, or even multi-color productions.

Small Blow Molding Machine

Categories : Electric Blow Molding Machines

Small-Continuous Type Blow Molding Machine This series model can produce small size containers ranging from 20mL to 10L for applications such as cosmetics, beverages, edible oil, pharmaceutical use, chemicals, housewares, and other industrial purposes. With the energy-saving system option, this machine can save up to 20% of power consumption. Some of the most common applications for small blow molding machines are: Lubricant oil bottles Laundry detergent bottles Cosmetic bottles Pesticide bottles Pharmaceutical bottles Multi-color kettles PVC cans Moreover, small blow molding machines can be customized according to the client’s needs of production: It can be a single or double station machine A visible stripe extruder unit can be added to observe liquid level It can include an auto-deflashing unit and many other features to make the machine as automatized as possible. An automatic extrusion blow molding machine is many times preferred because it leads to the reduction of manpower need which results in reduced costs, increased efficiency, and time savings for an organization.

Extrusion Blow Molding Machine PK-CS/CD/CS3/CS4/CS8/CS12

Categories : Extrusion Blow Molding Machines

Single Station Single/Double/Triple/Quadruple..12 Head Horizontal Operated Clamping System Production Volume:2ml~35L Multi layers: Co-Extrusion 1-6 Layers Multi cavities: 1~12 cavities Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion material Special function:View Stripe Clamping system:Toggle/3 Tie Bar/4 Tie Bar Driven Model: Hybrid servo motor drive system/ High performace hydraluic power saving system/Close loop proportional valve Support Parison controller/Auto Deflasing/Auto Recycling/Auto material feeder/Remote trouble shooting funciton/IML