Edible Oil Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging

Sauce Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging

Tea Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging

Water Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging

Juice Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging

PET Stretch Blow Molding Machine - Economy Affordable New Choice (EX Series)

Categories : Automatic Blow Molding Machines

● Blower power consumption for 1000 bottles: 2Wh. ● Air Compressor power consumption for 1000 bottles: 6 kWh compact space. ● Screw driven controlled by servo motor providing fast and smooth motion. ● Single lamp bilateral centralized heating, easy controlled within 3°C and energy heating. ● Low-pressure air compressor will NOT be required due to high-pressure recovery system. ● High efficient air recovery system up to 45%.

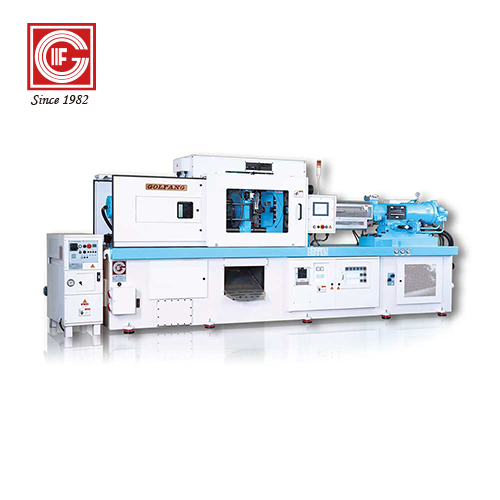

Single-Stage Injection Blow Molding Machine - IB Series

Categories : Injection Blow Molding Machines

Advanced Single Stage Blow Molding Machine Commonly used in the production of pet bottle, the mechanical design of Golfang Single Stage Blow Molding Machine is based on the blueprint of the world's most popular machine- the plastic injection machine with pressure booster ram system. Solid construction, durability, high precision, high stability, easy operation, easy maintenance and low running cost.

OSCILLATING TOWER ABC THREE-LAYER BLOWN FILM MACHINE

Categories : Blown Film Extruders

The ABC three-layer co-extrusion machine is your ideal choice for producing high-end plastic products, such as shrink films, agricultural mulches, electrical insulation films, packaging films, medical packaging films, stretch hood films. The raw material formula for each layer can be customized respectively according to your requirements. The oscillating haul-off unit provides excellent film gauge randomization, ensuring the production of high-quality and wrinkle-free films. The oscillating haul-off unit is also rather durable, and its equipment lifespan is much longer than the rotary die. Suitable for producing three-layer films for specific functions Recycled materials or CaCO3 is applicable to the middle layer in order to save material costs Die and air-ring specially designed for producing high-quality three-layer films 360° Oscillating Haul-off unit improves film thickness uniformity EPC (Edge Position Controller) Full customization according to your specific requirements

LDPE / LLDPE Blown Film Line(JC-LH Series)

Categories : Blown Film Extruders

JC-LH Series Blown Film Extrusion Line is designed for LDPE / LLDPE film production to achieve high output capacity with excellent film quality and transparency, fulfill the requirement for various applications. Application Material : LDPE / LLDPE Applciation Product : Agricultural Film / Shrink Film / Laundry Bag / Shopping Bag / Garment Bag Extrusion Ouptput : 120kg/hr.~380kg/hr.

Automatic-Blow-Molding-Machine-H Series

Categories : Automatic Blow Molding Machines

Our versatile and efficient plastic blow molding machine can produce a wide variety of products, from 5ml to 10L, with single-station or double-station configurations, monolayer or multi-layer, and 1 to 6 cavities. It is compatible with PE, PP, PETG, PVC, ABS, PA, PS, and co-extrusion materials. An optional view stripe line is also available. This machine is a great choice for businesses that need to produce high-quality plastic products with precise dimensions in a cost-effective and efficient manner. ● Apply for single station/ double station ● Production volume: from 5ml-10L ● Mono layer and multi layers are available ● Cavities: 1~6 cavities ● Apply for PE/PP/PETG/PVC/ABS/PA/ PS/ Co-extrusion material ● Option: view stripe line ● Support: Hybrid system, Parison control, auto deflashing, turn key solution

PET Blow Molding Machine - Wide Mouth Bottle

Categories : Horizontal Blow Molding Machines

Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.