High Speed Precision Vertical Injection Molding Machine-YQ Series

Categories : Vertical Injection Molding Machines

• Vertical four-pillar vertical clamping, with vertical injection. • The square pillar design comes with large mold size. The space within the column allows customers to install devices of automatic embedding and removing products. This allows automation for the whole machinery. • Big L / D ratio of screw, plasticizing evenly, suitable for injection molding of engineering plastics. • High standard computer control system with high precision injection pressure and high response injection speed. The quality is more stable for high-precision embedded injection molding products. • 1S single sliding: After mold opening, the lower mold will automatically slip in front of the operator for facilitating embedded molding operation. • 2S double sliding (Alternating double sliding): One mold for injection molding, another mold for taking out and putting on embedded parts operation. • 2SL double sliding (90°Alternating double sliding): One operator can operate independently. One mold for injection molding, another mold for material taking and putting on embedded parts. The two slidings are intersecting at 90 degrees, which can lower the production cost, and enhance the performance. • Able to combine automation and the high-speed injection can effectively enhance the production capacity. • A variety of circuit design (half closed servo hydraulic or high speed injection) to meet the customer’s requirements.

HDPE/PP Monofilament Extrusion Line (JC-MNP Series)

Categories : Extrusion Lines For Filaments and Yarn

JC-MNP series monofilament extrusion line designed with single-stage-drawing and heat setting. The line is specially conceived to process polypropylene (PP) and high density polyethylene (HDPE).

Continuous Thermoforming Machine SL-1220A

Categories : Vacuum Forming Machines

● High-rigidity design of machine bed: Integral casting design combined with high-tension steel plate structure offers steady and low noise operation.

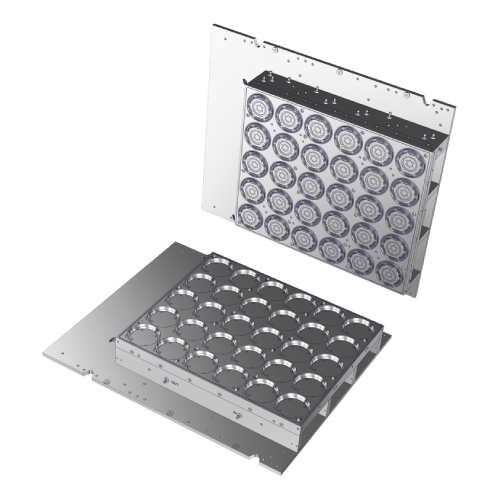

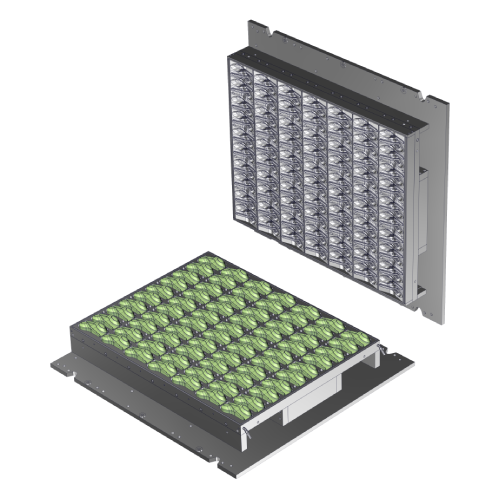

Cup Lids Thermoforming Moulds

Categories : Thermoforming Molds

Medium thermoforming machine, which means the forming sheet width is in between 800 mm to 1200 mm, like Asano, Cheng-Mei, Chudong, and VFK......etc Medium thermoforming mold is the most common mold that we build. So we are confident in proffering our customers a durable and precise mold. Normally, a robust production line includes forming, pre-punching, and punching station. HongZu is capable of building molds for all those stations.

Plastic Clamshell Container Moulds

Categories : Thermoforming Molds

Medium thermoforming machine, which means the forming sheet width is in between 800 mm to 1200 mm, like Asano, Cheng-Mei, Chudong, and VFK......etc Medium thermoforming mold is the most common mold that we build. So we are confident in proffering our customers a durable and precise mold. Normally, a robust production line includes forming, pre-punching, and punching station. HongZu is capable of building molds for all those stations.

Plastic Food Storage Container Lid Thermoforming Moulds

Categories : Vacuum Forming Machines

Built for medium-sized thermoforming machines, our molds deliver durability and precision. Enhance your manufacturing capabilities with HongZu.

Plastic Spoon Moulds

Categories : Thermoforming Molds

Medium thermoforming machine, which means the forming sheet width is in between 800 mm to 1200 mm, like Asano, Cheng-Mei, Chudong, and VFK......etc Medium thermoforming mold is the most common mold that we build. So we are confident in proffering our customers a durable and precise mold. Normally, a robust production line includes forming, pre-punching, and punching station. HongZu is capable of building molds for all those stations.

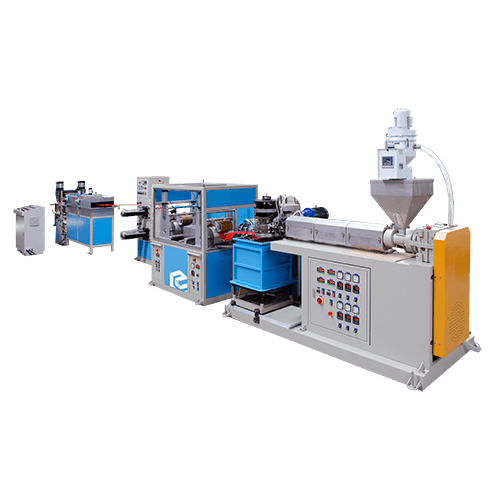

Net Extrusion Machine Line

The Everplast mesh production line is designed for high production demands. Provides high productivity, high precision, and excellent mesh surfaces. The screw is precision machined from high-quality alloy steel SACM-1 and nitrided to provide high performance and durability, ensuring high extrusion capacity and automatic temperature control. The entire machine's movement is controlled by a high-efficiency controller, making it easy to operate.

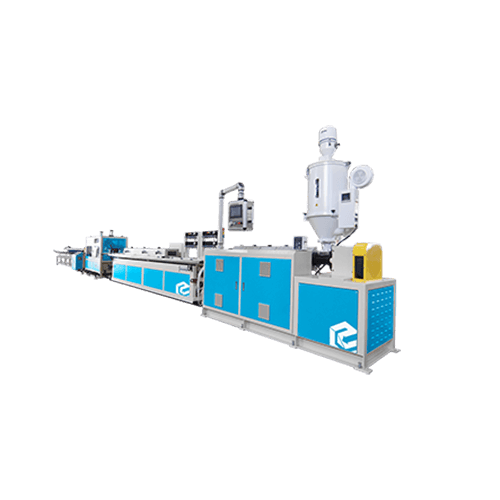

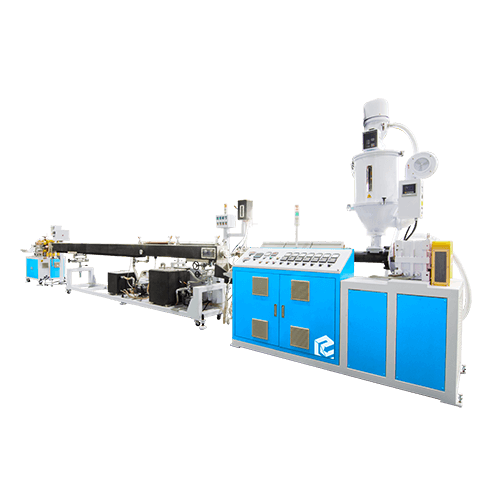

Profile Extrusion Machine Line

Categories : Extrusion Lines For Pipes and Profiles

Everplast's profile extrusion machine production line has many applications, including PVC building materials, decorative materials, the automotive industry, and other PP/ABS/PC/PMMA profiles of different materials in daily life. Everplast can plan suitable single screw/parallel type twin screw/conical type twin-screw production lines according to the profiles and materials required by customers. With excellent mold manufacturing and testing experience, we provide professional and comprehensive special-shaped extrusion processes and equipment.

Pipe Extrusion Machine Line

Categories : Extrusion Lines For Pipes and Profiles

Everplast's pipe extrusion machine lines use materials such as PVC, HDPE, LDPE, PE, PP, ABS, PS, PC, and PMMA to extrude products according to market needs and the characteristics of the plastic materials. Everplast's pipe production lines are widely used in construction, industry, agriculture, and other fields. Among them, in construction, it is mainly used for water supply, drainage, power pipelines, etc.; in industry, it is used in chemical pipelines, industrial discharge pipelines, etc.; in agriculture, it is used in irrigation pipelines, water conservancy projects, etc.

Medical Tube Extrusion Machine Line

Categories : Extrusion Lines For Pipes and Profiles

The medical industry is booming, especially medical tubes are one of the indispensable products. Therefore, Everplast provides modern and diverse medical tube sizes and materials (PVC/PE/TPU/PP/POE/EVA/FEP/PEEK... ) and precision requirements, a wide range of machine models (EMS-15, EMS-25, EMS-35, EMS-45, EMS-65, EMS-75, etc.) have been developed to meet customer production needs. . The Everplast medical tube extrusion production line also adopts a stainless steel exterior design, which facilitates customers to maintain the equipment in a clean room space. It has accumulated a lot of successful sales experience at home and abroad, and plays an indispensable role in today's medical tube equipment industry.

Cosmetic Bottle / Detergent Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging