Success Story - Plastic Squeeze Dryer

Categories : Plastic Washing Line

DW-350 / Plastic Squeeze Dryer / Washed PE Film / South Africa DW-300 / Plastic Squeeze Dryer / LDPE Film / Romania DW-350 / Plastic Squeeze Dryer / Washed PP Woven Bag / Spain Japan Subsidy Policy Assisting the Growth of Genius’ Squeeze Dryers

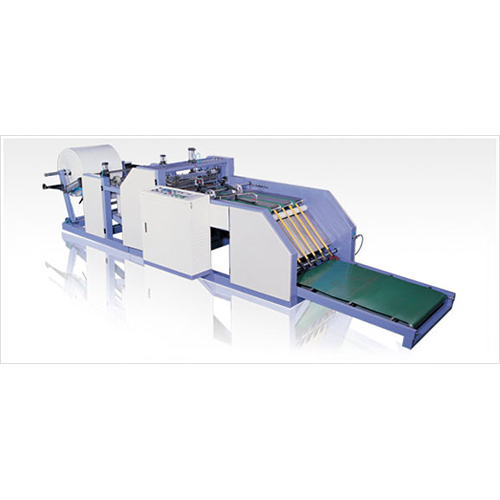

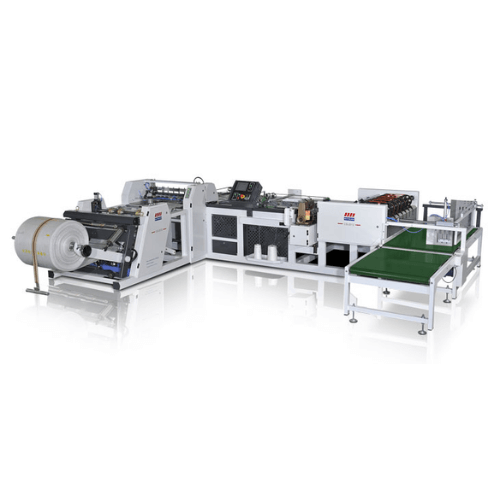

Automatic PP Woven Bag Cutting Machine

Categories : Cutting Machines

● Equipped Servo Motor For Precise Cutting Lenght (+- 1 mm) ● Equipped High Quality Alloy Steel Cutter ● Equipped Bag Mouth Anti-Stick Device

Reel to Reel Printing Line NRP-2012/6C (New Developed Model)

Categories : Flexographic Printing Machines

Reel to Reel Printing Line is the most efficient way for the PP woven bag printing, and capable of two side printing on the bag in the one process, based on the current market demand, we are able to proide 12 colors(each side 6 colors) Reel to Reel Printing Line. Our Reel to Reel Printing Line provide the best printing quality with high output (up to 120 meter / minute) and only one operator required. Decreasing the printing cost to the lowest. It is the most wisdom choice for printing.

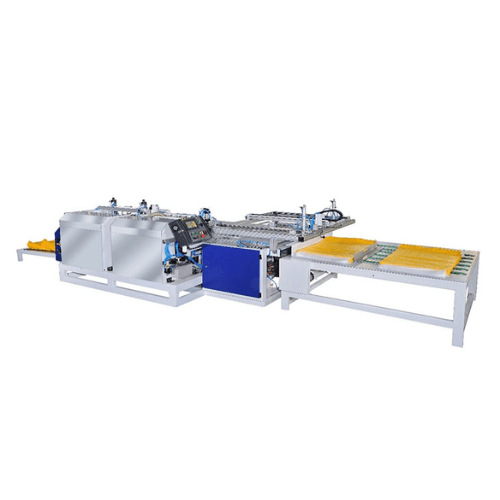

Roll To Roll Twist and Gusset Machine

Categories : Plastic Bag Making Machines

Various Gusset Depth for Different Bag Sizes are Available and Adjustable. Idea Design for Laminated Woven Bag, BOPP Woven Bag and Gusset Bag.

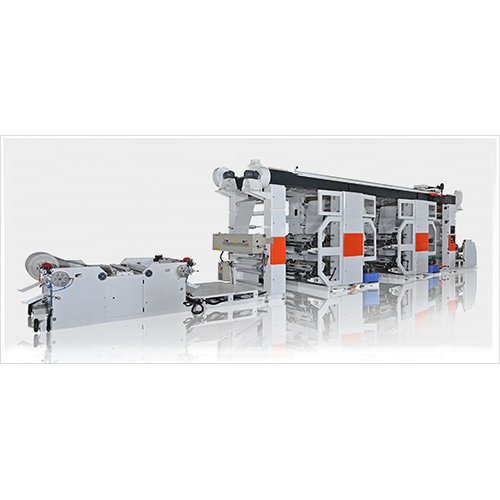

Reel to Reel Printing Line NRP-2012/10C (New Developed Model)

Categories : Flexographic Printing Machines

● Reel to Reel Printing Line is the most efficient way for the PP woven bag printing, and capable of two side printing on the bag in the one process, based on the current market demand, we are able to proide 12 colors(each side 6 colors) Reel to Reel Printing Line. ● Our Reel to Reel Printing Line provide the best printing quality with high output (up to 120 meter / minute) and only one operator required. Decreasing the printing cost to the lowest. It is the most wisdom choice for printing.

Bag Top Hemming Machine For PP Woven Bag (Bag Top Finishing Process) Model No: Top-Hem

Categories : Non Woven Production Line

With Liner Inserted Bag / And Also Normal Bags Without Liner Insertion. With Laminated Woven Fabric /And Also Non-Laminated Woven Fabric.

PP Woven Bag Automatic Cutting-Sewing Machine CS-2012(NEW DEVELOPED MODEL)

Categories : Industrial Knitting Machines

Equipped Two Servo Motors Equipped 90゚Bag Transfer Gripper Display Screen Operation Interface High Product Output (32-45 Bag / min) Cusfom-made designs are available

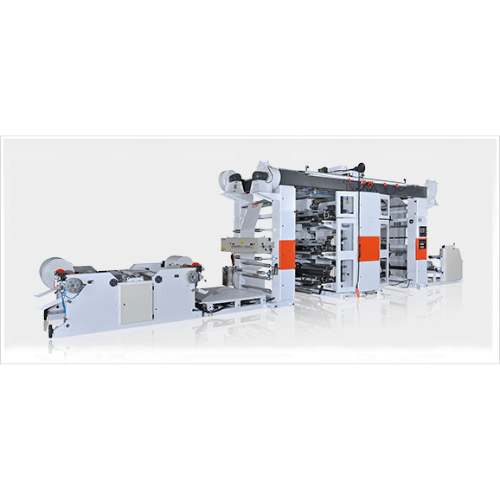

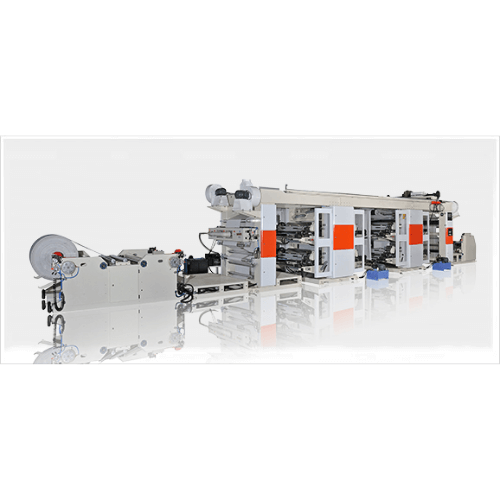

Reel to Reel Printing Line NRP-2012/8C (New Developed Model)

Reel to Reel Printing Line is the most efficient way for the PP woven bag printing, and capable of two side printing on the bag in the one process, based on the current market demand, we are able to proide 12 colors(each side 6 colors) Reel to Reel Printing Line. Our Reel to Reel Printing Line provide the best printing quality with high output (up to 120 meter / minute) and only one operator required. Decreasing the printing cost to the lowest. It is the most wisdom choice for printing.

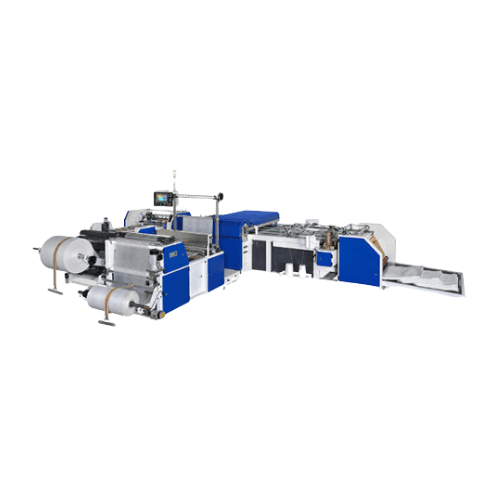

PE Film Liner Inserting Cutting-Sewing Line for Woven Bag CIS-2016

Categories : Cutting Machines

Fully Automatic In-Line Process for Liner Inserting-Cutting-Sewing. Applied for both functions: 1. Liner can be fully sewn with PP Woven Bag. 2. Liner also can be not sewn / loose inside PP Woven Bag. Without inserting liner, the machine can process for normal Cutting-Sewing function. Saving Manpower Hugely. With Excellence Quality & Stable Performance.

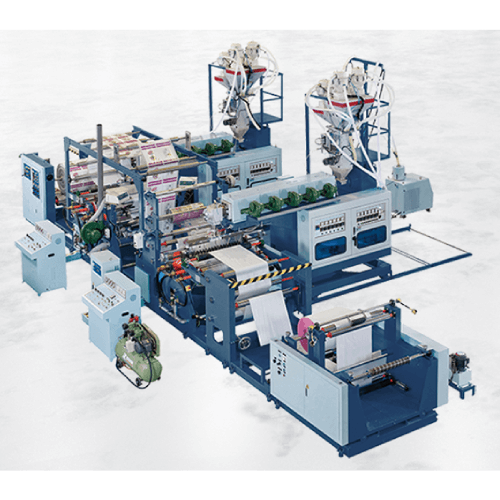

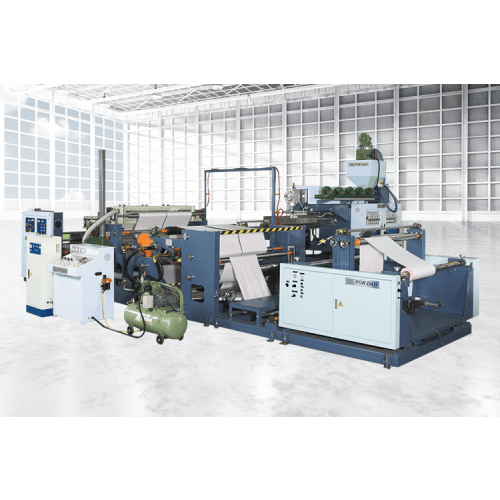

Flexographic High Speed Roll to Roll 8~12 Color Printing Machine with 2 Printing Stack and 4 Drying Oven (Direct Printing)

Categories : Industrial Lamination

The machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value. Newly developed printing machine offers max. line speed 250M/Min.

Double Side and Outside Lamination Machine

Categories : Extrusion Lamination Machines

The lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

Single Side by Turn Bar and Outside Lamination Machine

Categories : Extrusion Lamination Machines

The lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.