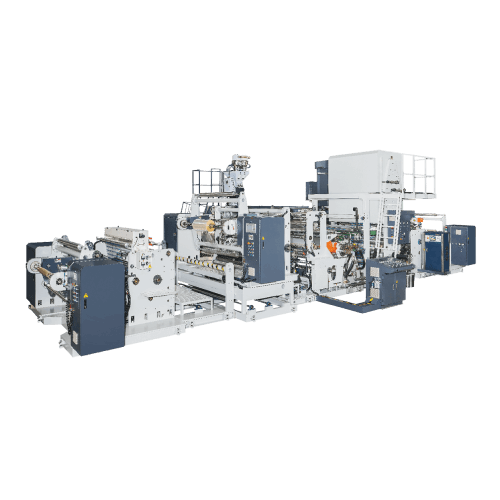

Classification : PP/HDPE Woven Bag Making Equipment

Country: Taiwan

Phone: 886-5-2215139 /886-5-2215149

Fax: 886-5-2219259

Contact Person: Ms. Lee

Max. machine speed: 250M/Min.

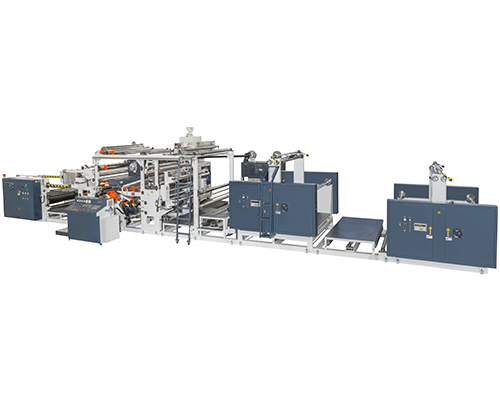

Standard including: Additional 2 ovens, CPC, In –feed servo control, Corona treatment, Non-stop Un-winder, Auto. Re-winder & servo control out-feed

Our flexographic roll to roll 8~12 color printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value.

Newly developed printing machine offers max. line speed 250M/Min.

- Steel made plate cylinder in each printing station decides the length of bag. Request to change plate cylinder when bag length is different.

- Simple color registration mechanism to ensure accurate printing quality.

- Equipped with Auto. Tension Controller and magnetic powder brake to regulate even tension prior printing.

- With Web Guiding Device to control the edge position for varying web width.

- Driven by timing belt for quiet running and precise transmission.

- With auto. ink circulation device to maintain uniform ink viscosity giving good printing quality.

- Available 4 deck oven facility provides excellent drying quality at high speed.

- Fully digitalized control setting on operator-friendly human machine interface (HMI).

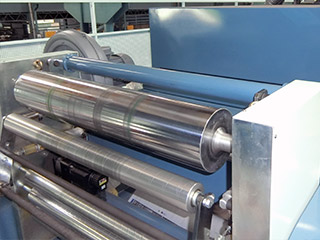

- High-Tech Doctor Blade with ceramic roller upon to customer’s request to remove the excess ink for the highest printing job.

- Available to have Auto. Roller Changer for rewinder to slice fabric roll on continuous operation, regulates the constant fabric tension, and auto. position rectification for evenly and tidily winding.

|

|---|

Included Device

- Double Side Corona Treatment Device

- Colored Touch Screen Type Industrial Computer Operation System (HMI)

- Auto. Ink Pump Circulation (Manual Type)

- Auto. Web Guiding System x 2 sets

- Auto. Tension Control (Control by Powder Brake and Load Cell)

- Auto. Hydraulic System for Separating Ink Roller and Anilox Roller

- Manual Printing Registration System without Stopping Machine

- Chromium Plated Surface Anilox Roller 200~300 LPI (By the customer’s request)

- Manual Type Hoist for Printing Cylinder Changing and Fabric Roll Loading x 2 sets

- Plate Cylinder Fixed on the Machine (By the customer’s request)

- Static Elimination Brush x 2 pcs

- 3 & 4 Drying Oven (Independent Control)

- Servo Control Out-Feed Device

- Servo Control In-Feed Device

- Complete Catwalk

- Central Position Controller (CPC)

- Cooling Roller with Rotary Joint

- 3” / 4” Air Shaft for Unwinder and Rewinder

- Non-Stop Roller Exchanging System for Unwinder

- “NEW TYPE” Auto. Roller Changing System for Rewinder

- Digital Camera Monitoring (8 cameras)

Optional Device