Automatic Tube Foiling & Capping Machine FCM 120-02

Categories : Capping Machines

1.This machine supports dual functions that can operate simultaneously or independently (Foiling + capping). 2. Equipped with intelligent Al inspection: tubes without orifice or with orifice defects wil not undergo Foiling. 3.Intelligent Al inspection ensures that tubes without foiling or with foiling defects wil not proceed to capping. 4. The capping torque value can be directly set on the HMI (Human-Machine Interface). 5. Products with orifice defects, foiling defects, or incorrect capping torque wil be automatically rejected through the defective product outlet. 6. This machine can also be equipped with a positioning photoelectric sensor to enable snap-on type operation.

Bag on Roll Machine With Automatic Rewinding Module and Auto Labeling

Categories : Bag Making Machine by Applications

1. Servo Motor Driven, Efficient mechanical structure From film to final bag, one process flow. 2. Unique designed Multi-Functional Folding Device can fold three types of bags. 3. Adjustable Multi-Functional Folding Device can fold any size of bag without changing the rack. 4. This can produce Coreless Rolls. 5. User-friendly Control Panel, easy to understand easy to operate. 6. Digital control for production length adjusting, precise and less wastage. 7. Simple design, assemble precisely, durable, and easy for maintaining. 8. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 9. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 10. High production efficiency to save labor and time.

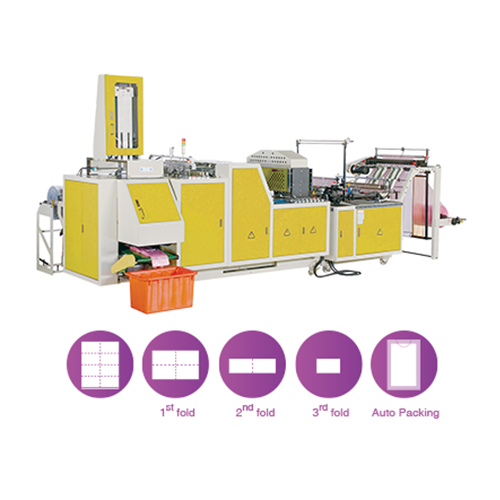

Fully Automatic High-speed Cutting & Sealing,3 Folding and Packing Machine

Categories : Sealing Machines

Fully Automatic High-speed Cutting & Sealing,3 Folding and Packing Machine by Servo Motor Control. ‧ Sealing & cutting,3 folding,auto-packing. ‧ Computerized human-touch screen control,easy operation.

Servo Motor Driven Zipper Bag Making Machine

Categories : Plastic Bag Making Machines

1. Servo Motor Driven, Efficient mechanical structure 2. User-friendly Control Panel, easy to understand easy to operate. 3. Digital control for production length adjusting, precise and less wastage. 4. Simple design, assemble precisely, durable, and easy for maintaining. 5. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 6. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically.

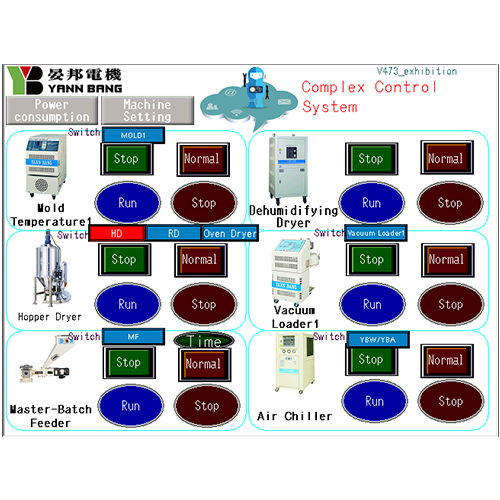

WT (Wise-Transit) Net 4.0

Categories : Industrial Software

Rapid and efficient data for analysis to provide well management. First Step heading to Smart Factory. Yann Bang, over 45 years’ experience, providing BEST Service. The automatic plastics processing can be controlled by the method of Industry 4.0, Modbus Protocol and RS-485, supplied by Yann Bang, professional experienced programming design and related compatible equipment, to offer you a best solution to a smart factory.

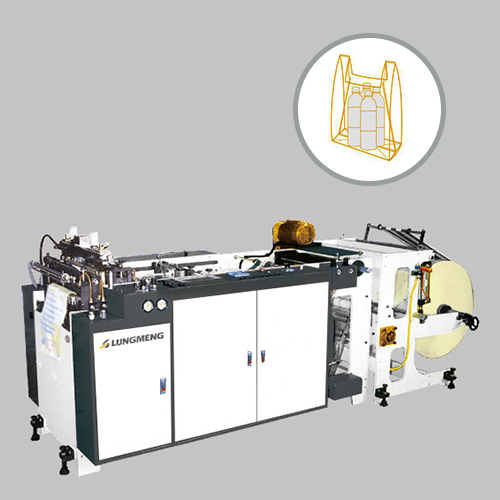

Servo-driven T-Shirt Bag Making Machine (Without Auto Punching

Categories : Bag Making Machine by Applications

TPA500FC, TPA-800FCD, TPA-1000FCD

Hot Air Tube Sealing Machine

Categories : Sealing Machines

-Monitor screen for easy operation. -Imported hot air equipment can make sealing fast and blazonry. -With automatic tube orientation.Cutting tail automatically after sealing. -Tube tail is durable after being sealed.

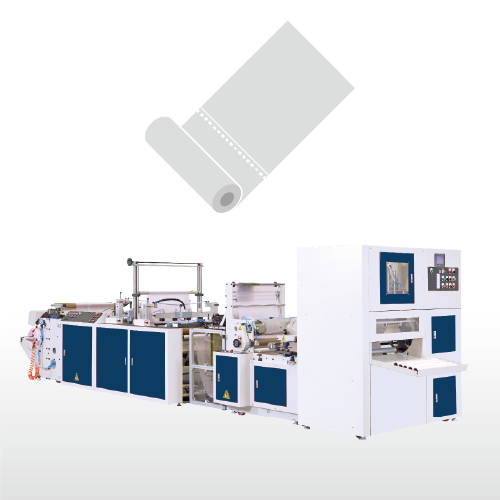

Fully Automatic High Speed Single Line With Core Garment Cover(Laundry Bag), Garbage Bag, Vegetable Bag, Table Sheet on Roll Making Machine / SBCR-750-OB

Categories : Plastic Bag Making Machines

Computer control over the entire process From film roll to final product, one process flow Automatic film feeding, cordination free from tension adjustment Automatically stop when running out of film / color scanning error / film feeding blocks or jam

Semi-Automatic Loop Handle Bag Making Machine LY-25LH

Categories : Plastic Bag Making Machines

Features Semi-automatic loop handle bag making machine. PLC motion control. Human-machine interface for easy setting.

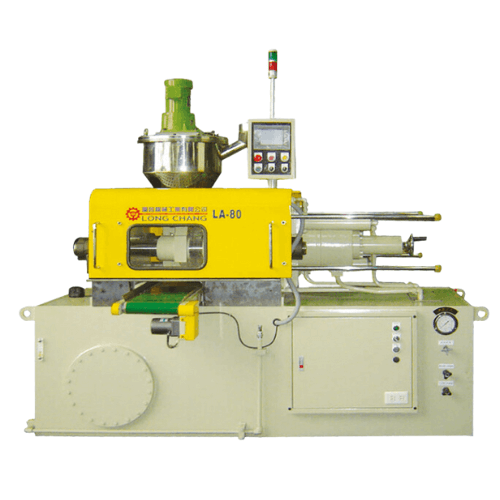

Automatic Oil Hydraulic Powder Forming Machine - LA/LB Series

Categories : Pressure Forming Machines

● Melamine powder, urea powder and phenol powder etc material molding forming use. ● Continuous automatic operation can be molded without help of an operator. ● Oil hydraulic type, high-speed powder forming. ● Molded tablets are uniform accurate in weight and size density. ● Hardness of tablets can be regulated by adjusting the hydraulic system. ● According to different sharp of molded tablets to change different punch size.

Knife-Cutting Bag Making Machine (GF-A812E-SV+C)

Categories : Cutting Machines

MODEL GF-24SE/SV GF-S600/SV GF-32SE/SV GF-S800/SV GF-40SE/SV GF-S1000/SV GF-50SE/SV GF-S1200/SV CUTTING WIDTH 600 mm 800 mm 1000 mm 1200 mm CUTTING LENGTH 800 mm FILM THICKNESS 0.01 - 0.1 mm PRODUCTION SE model : Max. 200 Cycles/Min ; S model : Max. 150 Cycles/Min REAR FEEDER 1 SET WITH GUSSET / FOLD / SLITTER / ADHESIVE TAPE APPLICATOR CONTROL PANEL 1 SET WITH HMI CONTROL SERVO DRIVE 1 SET, YASKAWA/JAPANL PRINTING SCANNE 1 SET, SICK/GERMANY CONVEYING BELT 1 SET COLLECTING TABLE 1 SET OPTIONS TENSION CONTROL, EPC, TRIANGLE FOLDING DEVICE, PUNCH HOLE DEVICE, MEXICAN HAT PUNCH DEVICE, ULTRASONIC SEALING DEVICE, PERFORATING SEALING KNIFE ENVELOP PUNCHING MOLD, AUTOMATIC STACKING TABLE glove making machine plastic gloves making machine

ULTRASONIC CLEANING MACHINE BOX TYPE ULTRASONIC CLEANING MACHINE

Overview and characteristics of ultrasonic cleaning machine ※ Ultrasonic cleaning is widely used, such as electrical appliances, electronics, automobiles, industrial machinery, etc.; optical lens degreasing, removal of surface attachments and cleaning parts, using a powerful ultrasonic cleaning machine with the cleaning Engineering to improve the production efficiency and the cleaning quality and working environment by using single-slot, multi-slot, and automatic methods.