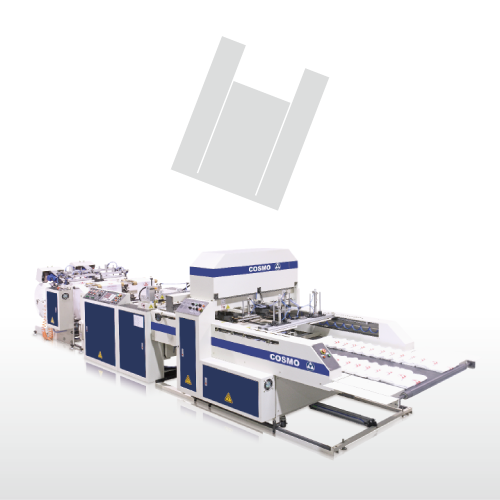

Fully Automatic High Speed 2 Lines T-shirt Bag Making Machine-ST-99

Categories : Bag Making Machine by Applications

Computer control over the entire process From film roll to final pruduct, one process flow Automatically stop when running out of film / film feeding blocks or jam

Twin-Cone High Speed Pelletizing Machine-Underwater Cutting

Categories : Plastic Pelletizer Machines

Suitable for high viscosity raw materials, such as PP, PMMA, TPU, PU, PLA, PET, TPU, PU, PLA and etc. High viscosity raw material. High Capacity, Low electricity usage, Easy to clean and change materials, Knead well, Underwater cutting

Mixer

Categories : Mixers and Blenders

The tank and agitating blades are made of stainless steel and the agitating blades can be easily removed and cleaned.It is perfectly safe for the operator and can produce sufficient mixing in a short time.

Ultrasonic Humidifier KT-100A

1.Ultraquiet, No Water Spots. 2.Energy efficient with low power consumption. 3.Easy installation and operation. 4.With humidity control and mist low high. 5.Safety shut-off when no water in tank. 6.Easy clean and Easy-To-Fill water tank.

9" plate (3 partition)

Categories : Containers

Product Number: EG-93 Color: White Material: Fiber Shape: Round

High Speed Rotary Die Inflation Machine For PP( AKPP-65)

Categories : Blown Film Extruders

HIGH SPEED ROTARY DIE INFLATION MACHINE FOR PP

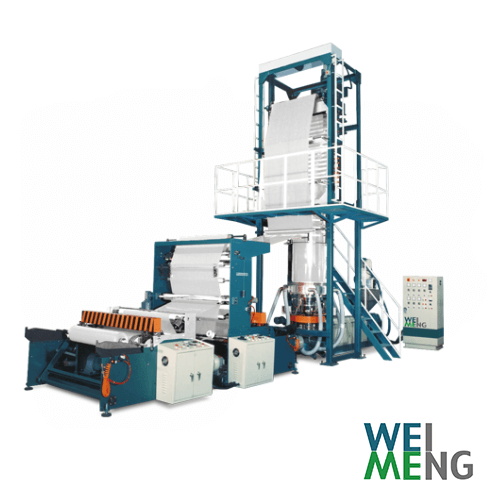

HDPE Blown Film Machine

Categories : Blown Film Extruders

HDPE Blown Film Machine In the past 30 years, we have been keeping receiving very good reputation from our worldwide customers on our quality products and satisfactory services.

Slitting Machines ULTRA/ UHS

Categories : Slitters and Rewinders

The SLIT-UHS series slitter is ideal for the serious slitting all types of flexible packaging materials as well as label stock & paper. The slitter comes standard with razor cutters and groove roller configuration. A shear cutter system is offered as option for paper and other pressure sensitive materials. The machine uses three AC Vector Drives and has automatic tension on unwind and rewind controlled through easy-to-use PLC & MMI touch screen. The machine features a vacuum roller that keeps the material stable during operation at high speeds 600m/min. Friction rings are used on rewind shafts to ensure the production of quality slit rolls when the film thickness varies.

Fully Automatic PE Cling Film Rewinder Machine-RW-1 Series

Categories : Slitters and Rewinders

Designed to rewind small rolls from jumbo rolls RW-1 for rewinding fixed width film 300mm, fully automatic feed paper core, rewind, cut & change paper core. RW-2 for rewinding width film 200-550mm, manual feed paper core, cut & change paper core RW-3 for rewinding fixed width film 500mm, fully automatic feed paper core, rewind, cut & change paper core RWA for rewinding width film 300-530mm, fully automatic feed paper core, rewind, cut & change paper core.

SEMI-AUTOMATIC PE CLING/ STRETCH FILM REWINDER MACHINE-RW-2 Series

Categories : Slitters and Rewinders

Designed to rewind small rolls from jumbo rolls RW-1 for rewinding fixed width film 300mm, fully automatic feed paper core, rewind, cut & change paper core. RW-2 for rewinding width film 200-550mm, manual feed paper core, cut & change paper core RW-3 for rewinding fixed width film 500mm, fully automatic feed paper core, rewind, cut & change paper core RWA for rewinding width film 300-530mm, fully automatic feed paper core, rewind, cut & change paper core.

Blow Moulding Machine for Jerrycan, Plastic Bottle, L-ring Drum

Categories : Electric Blow Molding Machines

Blow Moulding Machine for Jerrycan Plastic Bottle, L-ring Drum

PPV Proportional Pinch Valve

Categories : Separators

Product Serial: PPV Pinch valve works in a way to open or to close a fluid path in a flexible tube by squeezing or pinching the tube. With a proportional pinch valve, the shaft that pinches the tube is driven by a stepper motor, thus that the extent of pinching can be adjusted, which indirectly controls the fluid flow rate inside the tube. The advantage of using a pinch valve is that it has no contact with the fluid, making it an ideal option for biotechnology processing, food industry, dosing system, blood process/analytical, CIP and SIP process, and biopharmaceutical equipment. Our PPV series pinch valve is driven by the PM series driver that accept either analogue ( 0-10V or 4-20mA) or digital RS485 modbus signal. What is a Proportional Pinch Valve? A Proportional Pinch Valve is a type of pinch valve that combines the characteristic and features of a pinch valve and a linear stepper motor. It is a great way to control fluid flow or fluid pressure in applications that emphasize sterile, clean, non-contact, avoid cross-contamination environment, such as Biotechnology Chemical Processing Dispensing, Filling, & Mixing Process Equipment Bioreactors Medical Devices Pharmaceuticals Life Sciences Food Processing In this article, we will start by introducing what type of proportional pinch valve KaoLu could offer, followed by the working principle, and when should you use a proportional pinch valve, and then conclude with what you should consider before making a decision on which valve to purchase. What type of Proportional Pinch Valve does KaoLu offer? KaoLu offers mainly two types of proportional pinch valve – miniature and high torque version. Miniature version: please click on photo to product brochure ,or visit https://www.genndih.com/pinch-valve/proportional-pinch-valve.html Three versions are now available: PPV-04, for tube outer diameter (O.D.) 3.5 – 4.5 mm (~0.125” to 0.188”) PPV-06, for tube O.D. 5.5 – 7 mm (~ 0.25” ) PPV-08, for tube O.D. 7 – 9 m (0.375”) The tube O.D. is flexible because we are using flexible plastic tube, and as long as the tube can fit into the insertion slot, it will be functional. The higher torque version is suitable for soft and more rigid tubing, up to durometer of 75 shore A. Please click on photo for product brochures, or visit https://www.genndih.com/pinch-valve/proportional-pinch-valve.html It is available to up 5 different sizes PPV-930-64 – tube O.D. 6 – 7 mm (~ 0.25”) PPV-930-95 – tube O.D. 9 – 10 mm (~0.375”) PPV-930-127 – tube O.D. 12 – 13.4 mm (~0.5”) PPV-930-191 – tube O.D. 18.6 – 19.6 mm(~0.75”) PPV-930-254 – tube O.D. 24.8 – 25.8 mm (~ 1”) All our proportional pinch valve can be controlled by either analogue (0-10V or 4-20mA) or digital signal. There is also an option for encoder. For the correct selection of product, please contact our product consultant. We also provides a video demo on how proportional pinch valve function, please visit and subscribe for our latest videos. https://www.youtube.com/watch?v=5z31SR9wqgk What is the Working Principle of a Proportional Pinch Valve? A proportional pinch valve combines the features and advantage of a pinch valve and a linear stepper motor. Let’s firstly introduce you the concept of these two items. Pinch Valve A pinch valve works in a way by pinching or squeezing a flexible plastic tube through a shaft that can be controlled by solenoid electromagnetic principle, by pneumatic pressure, or by a linear stepper motor. Pinch valve is especially useful in applications that does not allow valve to be in contact with the fluid inside the tube, such as chemical reagents, food, corrosive fluid…etc. A traditional pinch valve only provides full open or full closure function, and the disadvantage is that there is a flow rate drop when the tube is inserted into the pinch valve, and there is no way to control fluid flow rate. Linear Stepper Motor A linear stepper motor is a type of actuator that used the characteristic of a stepper motor to achieve linear motion. The degree in which one can control a step distance and torque is greatly dependent on the control system and the stepper motor quality and characteristics. A stepper motor is commonly used when one requires high resolution, high repeatability, and high torque. Pinch Valve + Linear Stepper Motor = Proportional Pinch Valve The combination of both provides an excellent solution for application that requires an automation on process line that requires sanitary environment and applications that require cleanliness and sterility, as well as highly accurate incremental flow or pressure regulation. This eliminating the need for multiple-valve, high-maintenance assemblies, and this single valve offers a compact, efficient solution. When should I use a Proportional Pinch Valve? KaoLu is expert in pressure and flow regulation. Please refer to the graph below: Pressure Regulation: The left had side is the control of inline pressure with a traditional on/off pinch valve. The right hand side shows the pressure control with a proportional pinch valve. In a process line that does not allow fluid to be contaminated, one could consider a proportional pinch valve to adjust the inline pressure by controlled the opening of the tube via a proportional pinch valve. With a fine step control, the pressure could be adjusted in a high resolution manner. Flow Regulation: The graph shows that the inline fluid flow rate could be regulated by a proportional pinch valve. The curve could be shift leftward with either a higher resolution stepper motor control or by adjusting zero offset of the pinch valve. With a proportional pinch valve, one can easily control (non-contacting method) the inline fluid pressure and flow rate, this offers a great advantage to many industries. What should you consider when purchasing a Proportional Pinch Valve? 1. Tube: outer diameter, material, shore A, inner tube pressure 2. Performance: resolution, repeatability, can achieve desired accurate flow or pressure control 3. Control: analogue or digital control We called it TPC. It is important to understand the characteristics of the tube you are using and the operating pressure. Sometimes, a suitable tube may not work if you have a high inner tube pressure which the pinch valve could not squeeze or pinch at all. Secondly, the performance of the proportional pinch valve should be taken into account when choosing which brand of proportional pinch valve is suitable for you. With KaoLu’s proportional pinch valve, we are able to achieve up to 40000 steps per revolution and the velocity in which the pinch shaft moves to squeeze and the torque of the motor could be calibrated easily by our customers to suit different requirements. The third important factor is control method. With our digital control method, it is possible to operate the valve half a mile away from the valve itself. We also provide RS485 holding register where the user could adjust zero offset and other parameters to fit customized solution. Please visit our product website for further information. https://www.genndih.com/pinch-valve/proportional-pinch-valve.html and remember to visit our youtube channel and subscribe for latest video updates: https://www.youtube.com/channel/UCjQ9bjuSOT_csnVA9if4_EQ/videos

4 Shaft Auto Cutter

Categories : Cutting Machines

Application:To cut the variety of tape rolls, e.g.: double-sided tape, masking tape, Electrical Tape, construction tape, other kinds of tapes. yicheen

Stainless Hopper Dryer for Optics (HD-S / DHD-S)

Categories : Dryers and Dehumidifiers For Plastic Materials

The perfect dry capacity is special for optics and electronics use. Unique design is dust-free and clean-free. Stainless and polish one-unit hopper is compact and light weight to install on the molding machine directly. To see the material level through a sight glass is to make working more efficient. DHD-S Series - The unique insulated hopper can stand heating repeatedly in high temperature. High security and well dehumidifying.

Accumulator Double Head Blow Moulding Machines

Categories : Automatic Blow Molding Machines

Accumulator Double Head Blow Molding Machines Mono Layer and Multi-layer Accumulator Head Type Blow Moulding Machine. For producing 20 liter to 1000 liter volume, all kinds of jerry can, containers, air duct and industrial blow moulding products.

Ultrasonic Skin Scrubber KUS-028

Skin Scrubber KUS-028 is a portable and handy device using with rechargeable battery. It provides 25,000 times micro vibration per second which can penetration in skin massaging as well as cleaning. It will efficiently clean up the skin without harm, exfoliate the dead skin and make the skin more healthy, smooth, brighten & refreshed.

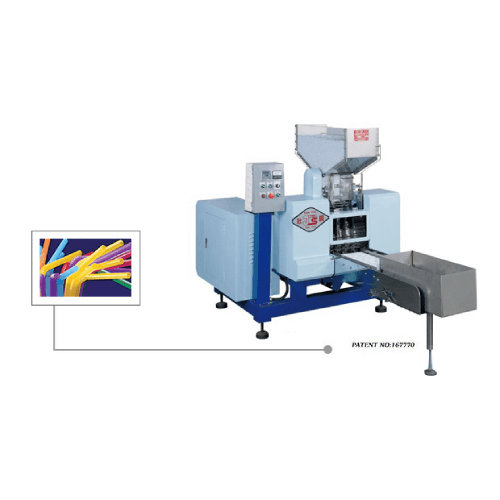

JS 165 HIGH SPEED FLEXIBLE DRINKING STRAW BENDING MACHINE

Categories : Extrusion Lines For Pipes and Profiles

PRODUCTION CAPACITY : 600-700 pcs/min CYCLIC PRODUCTION : 45 pcs/cycle This newly designed drinking straw bending machine dramatically increases productivity. Compactly constructed for reduced space requirments, this high efficiency machine provides user-friendly automatic operation.

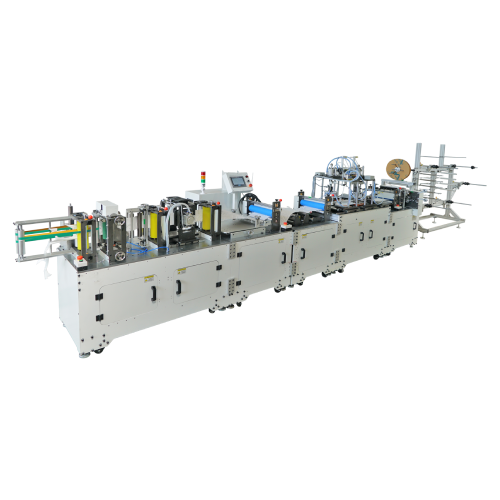

Perforating Bags on Roll Machine with Core by Servo Motor Control Model: CWAP-SV

Categories : Plastic Bag Making Machines

Perforating Bags on Roll Machine with Core by Servo Motor Control Model: CWAP-SV

Mega Aspirator

Categories : Plastic Waste Recycling Machines

This product is a new label separator developed by Boretech. The principle is to make use of the different aerodynamic characteristics of the flakes and the label.Relying on the negative pressure air flow generated by the centrifugal fan, it can accurately and quickly separate the label and other light impurities in the PET flakes. Scope of application: 10-16mm PET, PP, PE flakes Material status: dry material or wet material

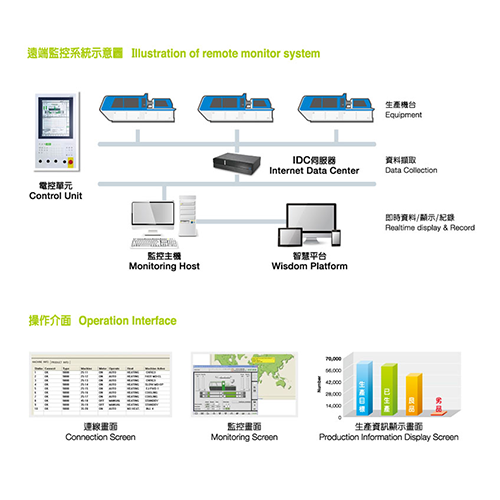

Remote Monitoring System

Categories : Industrial Software

The monitor screen is the same as the IMM controller, which is more friendly for users. Also it is easy to oversee the production status moment-to-moment through mobile devices such as cellphones and tablets.The monitoring enables to be set based on the user requirement and different grades of authority. Single host could simultaneously monitor numbers of equipment.