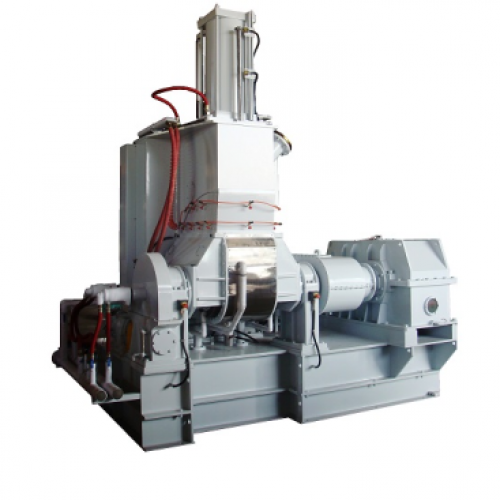

Super Cooling Dispersion Kneader

Categories : Dispersion Kneaders

This machine most suitable kneading application for all kind Rubber, Plastic and Chemical materials. This machine with following features: High quality processed products ╱ Easy for operating ╱ Easy for color changing╱Extra big rotor jacket for super Cooling ability╱Low temperature mixing╱One pass mixing.

Dispersion Kneader (Hydraulic ram)

Categories : Dispersion Kneaders

This machine most suitable kneading application for all kind Rubber, Plastic and Chemical materials. This machine with following features: High quality processed products/Easy for color changing /Easy for operating/increase production.

Standard Model Dispersion Kneader

Categories : Compounding Lines

Compounding For Rubber、Plastic & Chemical Industries Features: This machine most suitable kneading application for all kind Rubber, Plastic and Chemical material This machine with following features: High quality processed products. Easy for operate. Easy for color change.

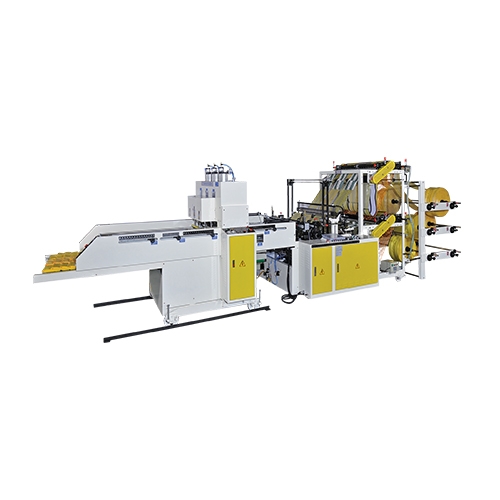

Double Layer (6 Lines) T-Shirt Bag Cutting & Sealing Machine Model: CWA2+6+P-800-SV/CWA2+6+P-1000-SV

Categories : Bag Making Machine by Applications

‧ Automatic electronic control. Use pluging type IC easy replacing. ‧ Electromagnetic clutch and brake keep bags cutting and sealing accurately. ‧ The machine will stop automatically. When 1. The bags becomes super-imposed or overlapped. 2. Film finished. 3. The temperature not reaching setting. 4. Air pressure not enough. ‧ This machine use penumatic punching machine, low power consumption, low noise level, no hot air pollution, smooth & perfect punching.

Plastic / PP Woven Bag Cutting Sewing Machine

Categories : Sealing Machines

The HY7/SP-150H has a capacity of 24-32 bags/min, with length adjustment and auto bag gathering systems. The unit can also be equipped with auto mouth open and bottom folding system, making bag production faster.

Taiwan Front Body Kit Injection Mould

Categories : Injection Molds

Motorcycle Injection Molds - Taiwan Front Body Kit Injection Mould Exterior parts for brand e.g. HONDA, SUZUKI, MAZDA etc… The appearance of surface mainly finished in texture or plating. Meet customer high requirements for product fitting.

Grille Injection Molds

Categories : Injection Molds

Grille Injection Molds Applications: Grille for Cars Air bag Cover Cup Holder for Cars Dashboard Vent for Cars

TPE for Automotive Parts - TSO/TO Series

Categories : TPR (Thermoplastic Rubber)

EVERLON® is a kind of SEBS as TPE, which the middle of it is the Styrene Ethylene rubber and the end of it is the Polystyrene. Through the catalytic reaction, it include the weatherability and stability of heat-resistant ability. Thermoplastic Vulcanizates (TPVs)based on EPDM. Applications:Antena, Exhaust duct, Window seal, Fender. Ever Polymer has the mission to satisfy all the application needs for thermoplastic elastomers (TPE) raw materials in the market. TPE TPR tpe material tpe material eco friendly tpe material manufacturer tpe material properties tpe material toxic tpe plastic recycling tpe raw material tpe rubber what is tpe material tpe material safety

Water Transfer Printing Dipping Machine- Automatic- JK-350TT

Categories : Hydrographic / Water transfer Machines

One of our popular dipping machines. Continuously Flow Dipping Machine is a very excellent system with 1.2 meters ~ 1.5 meters / minutes (according to product) high continuous film flow speed. By its perfect design of adjustable triangle transmission system, this unit is capable to work with various shape of decoration in different angle adjustment. The automatic dipping machine is perfect for mass production. It’s perfect to decorate parts for: automotive industry, switch and sockets, shoes, cosmetic caps, glasses, paintball loader, etc... The machine can be customized according the customer’s products. The advantage of the automatic continuous flow dipping machine is the stable quality of the final product and great quantities of daily production.

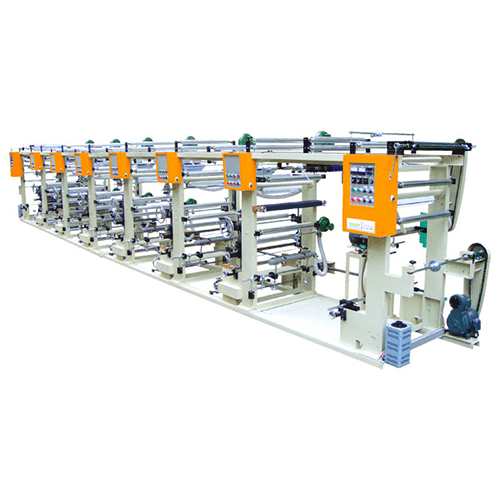

Automatic High-Speed Rotogravure Printing Machine

Categories : Rotogravure Printing Machines

This machine is designed for printing on materials such as OPP, PE, PP, PVC, shrinkable film, wrapping paper, and aluminum foil

Aluminum Foil Coating Machine Tandem Type (WAC-DT Series)

Categories : Industrial Lamination

For its strong characters of odor free, lightproof, antioxidant, and flavor preservation, aluminum foil has become one of the most popular solutions for soft packing industries. Laminated aluminum foil has multiple advantages: antioxidant, moisture-proof, also avoiding from direct sun exposure and etc., and it not only does help extend the expiration period but also increase the product value by effective visual presentation through its metallic glossy texture. For years, aluminum foil has been widely used in many different industries, such as pharmaceutical and food sectors; to create satisfactory solution to the demand of those sectors, it requires specific machinery technologies in aluminum foil printing or coating. This model is specially designed for aluminum foil coating. The whole structure of machine is consisted of primer coating unit, HSL coating unit , So it allows same side or two side coating in one go. The coating process options are available options for different requirements of direct gravure coating & semi-flexo coating. The high efficient drying tunnel is set on top of the machine . For feeding operation, double shaft turret type automatic splicing devices both on unwinding/rewinding units. The whole machine is controlled by PLC digital control system and HMI touch screen interface, which makes coating production easier and more convenient.

Aluminum Foil Coating & Laminating Machine (WACL-1300)

Categories : Industrial Lamination

WACL series is not just a convention dry laminating machine. The cold form foil is very much concerned proper & precise tension control to handle such thick laminates. In terms of tension control, this machine has mainly designed for Alu-alu foil multi-layers lamination. The arch dryer roller has synchronized with line speed, it’s very low friction and steady when film pass through the dryer. The internal drying chamber has safety LEL detection, this system can automatically discharge when detected high VOC occur during the production. This machine also combined heat seal lacquering coating function. Additional primer coating unit before lacquering unit, so it allows to apply two side (primer+heat seal) coating in one pass. The coating unit has alternative function with direct gravure and semi-flexo coating systems. Coating trolley along with self-pump system and able for quick job change.