Classification : PRODUCTS

Country: Taiwan

Phone: 886-6-2531251

Fax: 886-6-2535271

Contact Person: Ping Shun Huang

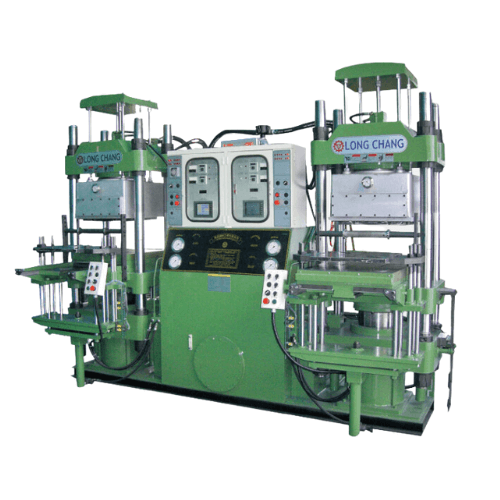

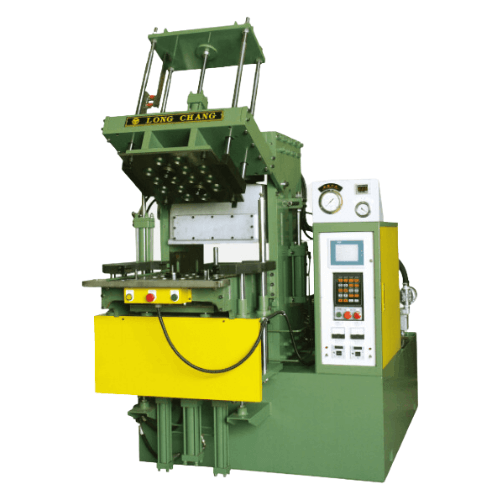

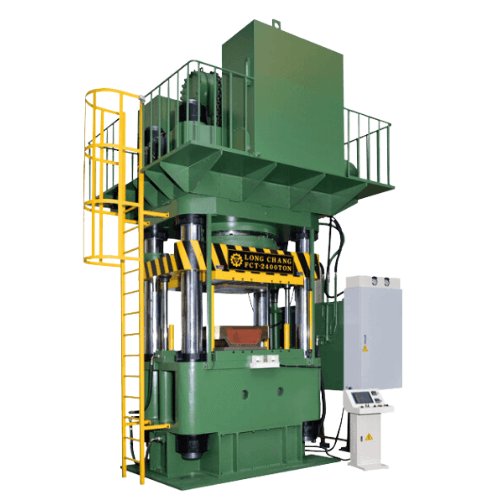

- Natural rubber, synthetic rubber oil-proof & heat-proof rubber and reclaimed rubber products.

- Automobile parts, electronic components, diving items, oil seal and sports goods, and other rubber products.

| SPEC | TYPE | FCR-150 | FCR-200 | FCR-260 | FCR-300 | FCR-400 | FCR-500 | FCR-600 | ||||

| MAX SHOT VOLUME | C.C. | 50-1000 | 50-1000 | 50-2000 | 50-3000 | 50-3500 | 50-4000 | 50-5000 | ||||

| INJECTION PRESSURE | KG/CM2 | 1900 | 1900 | 1900 | 1850 | 1850 | 1800 | 1800 | ||||

| HYDRAULIC PRESSURE | KG/CM2 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | ||||

| SCREW DIAMETER | MM | 35 | 45 | 45 | 45 | 45 | 50 | 50 | ||||

| SCREW SPEED | PRM | 30-120 | 30-120 | 30-120 | 30-120 | 30-120 | 30-120 | 30-120 | ||||

| MATERIAL SIZE(TxW) | MM | 6x50 | 6x50 | 6x50 | 6x50 | 6x50 | 6x50 | 6x50 | ||||

| CLAMPING FORCE | TON | 150 | 200 | 260 | 300 | 400 | 500 | 600 | ||||

| OPENING STROKE | KW | 400 | 500 | 500 | 540 | 540 | 600 | 700 | ||||

| DAYLIGHT | MM | 600 | 650 | 650 | 740 | 740 | 800 | 900 | ||||

| PLATE SIZE | MM | 500x500 | 500x600 | 500x600 | 600x650 | 600x650 | 650x700 | 760x870 | ||||

| MOTOR | HP | 10 | 15 | 20 | 25 | 30 | 40 | 50 | ||||

| HEATING CAPACITY | KW | 8 | 10 | 10 | 12 | 12 | 14 | 16 | ||||

| HEATING TRANSFER | HP | 1/2x2 | 1/2x2 | 1/2x2 | 1/2x2 | 1/2x2 | 1/2x2 | 1/2x2 | ||||

| SYSTEM PRESSURE | HP | 210 | 210 | 210 | 210 | 210 | 210 | 210 | ||||

| TANK CAPACITY | GAL | 150 | 150 | 150 | 200 | 200 | 250 | 250 | ||||

| L | 1950 | 2000 | 2000 | 2200 | 2200 | 2300 | 2500 | |||||

| MACHINE DIMENSIONS | MM W | 2050 | 2350 | 2350 | 2400 | 2400 | 2530 | 2750 | ||||

| H | 3450 | 3600 | 3600 | 3500 | 3500 | 4730 | 4950 | |||||

| MACHINE WEIGHT | KG | 5500 | 6800 | 7500 | 10000 | 105000 | 13000 | 16000 | ||||

| WRAPPING WEIGHT APPROX | KG | 5800 | 7100 | 7800 | 105000 | 115000 | 13500 | 16500 |