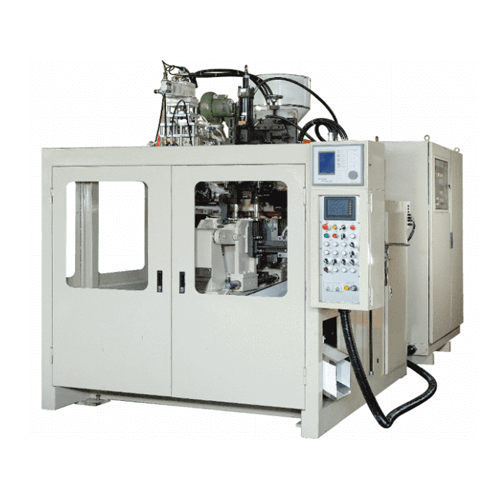

Blow Molding Machine PBS-605~705 Series

Categories : Horizontal Blow Molding Machines

Durable and horizontal traveling mold carriage combined with German linear motion guides for maximum stability. The series is excellent for producing medium and large sized containers. Available to equip with an auto deflashing device and take-out robot to achieve fully automatic and highly efficient production. 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, maximum operational convenience and user-friendly operation.

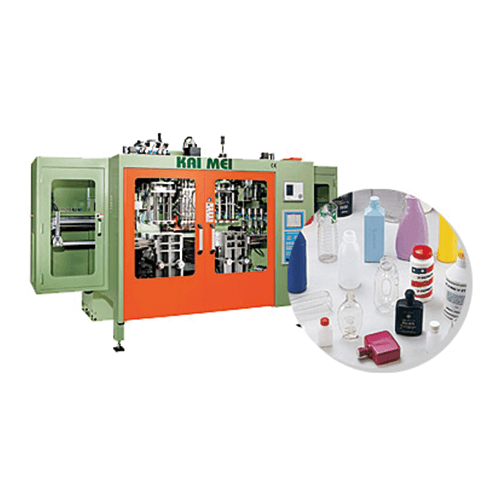

Blow Molding Machine PBSS SERIES 605 / 705 (S / D / T / Q)

Categories : Injection Blow Molding Machines

Double Stations Series Double station machine, full automatically, suitable for producing high-production runs of medium size bottles, ex. Cosmetic bottles detergents, etc. Mold-platen moves properly with high stability and high efficiency Three tie-bar horizontal traveling mold carriage combined with German linear motion guides for outstanding performance and high efficiency. This series is designed to meet high production and small size container requirements. Available to equip with auto de-flashing device and take out robot to achieve fully automatic and highly efficient production. 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, convenient and user-friendly operation.

Blow Molding Machine PBSS - 905 O/1005 O

Categories : Electric Blow Molding Machines

It is designed for small containers Mouth-to-Mouth design. Mouth-to-Mouth design can improve two-time production for double-station machines. It creates a unique and new mold design and auto cutting device. It can increase machine stability and decrease defective rates. This is the latest high-producion machine technology.

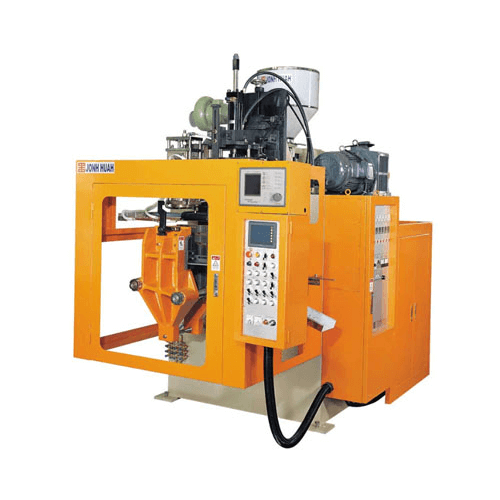

Blow Molding Machine PBSS SERIES - 905 / 1005 (S / D / T / Q)

Categories : Horizontal Blow Molding Machines

Powerful, crank-type mold clamping system combined with German linear motion guides for outstanding performance and high efficiency. This series is designed to meet high production requirements. Available to equip with auto deflashing device and take-out robot to achieve fully automatic, highly efficient production. 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, maximum operational convenience and user-friendly operation.

JN Series-Single Station

Categories : Automatic Blow Molding Machines

●Hydraulic type Automatic Blow Molding Machine. ●Automatic production design. ●Heavy-Duty clamping structure design. ●Mold Open/Close/Move by precision linear guide and finished bottles come out in line for next process. ●Gearbox drive extruder directly. ●Scraps centralize management. ●PLC control with Touch Screen for time, pressure, flow,...etc. ●Diversified parison knifes and multihead choices depend on the requirement. ●Energy saving system for hydraulic system.

JS Series-Double Station

Categories : Automatic Blow Molding Machines

●Hydraulic type Plastic Blow Molding Machine. ●Automatic production design. ●Mold Open/Close/Move by cylinder. ●Gearbox drive extruder system. ●PLC control with Touch Screen for function, time, pressure...etc. ●Diversified parison knifes and multihead choices depend on the requirement. ●Proportional pressure hydraulic system. ●Especially for 2 liter bottle and 5 liter bottle.

JN Series-Double Station

Categories : Automatic Blow Molding Machines

●Hydraulic type Automatic Blow Molding Machine. ●Automatic production design. ●Heavy-Duty clamping structure design. ●Mold Open/Close/Move by precision linear guide and finished bottles come out in line for next process. ●Gearbox drive extruder directly. ●Scraps centralize management. ●PLC control with Touch Screen for time, pressure, flow,...etc. ●Diversified parison knifes and multihead choices depend on the requirement. ●Energy saving system for hydraulic system.

JS Series-Single Station

Categories : Automatic Blow Molding Machines

●Hydraulic type Plastic Blow Molding Machine. ●Automatic production design. ●Mold Open/Close/Move by cylinder. ●Gearbox drive extruder system. ●PLC control with Touch Screen for function, time, pressure...etc. ●Diversified parison knifes and multihead choices depend on the requirement. ●Proportional pressure hydraulic system. ●Especially for 2 liter bottle and 5 liter bottle.