Single-Stage Injection Blow Molding Machine - IB Series

Categories : Injection Blow Molding Machines

Advanced Single Stage Blow Molding Machine Commonly used in the production of pet bottle, the mechanical design of Golfang Single Stage Blow Molding Machine is based on the blueprint of the world's most popular machine- the plastic injection machine with pressure booster ram system. Solid construction, durability, high precision, high stability, easy operation, easy maintenance and low running cost.

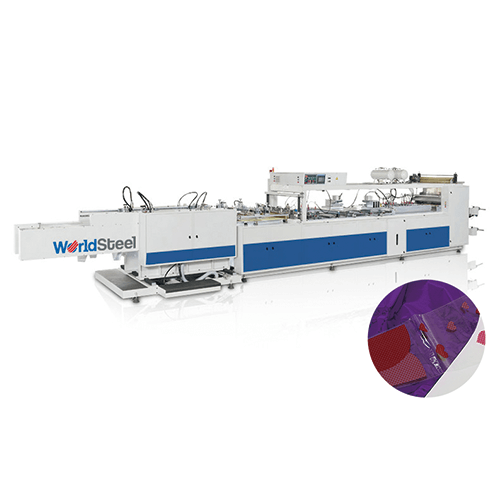

Flower Shape Bag Making Machine

Categories : Bag Making Machine by Applications

The World Steel flower sleeve bag making machine can be used for more than just flower bags. Coupled with our perforation machine, punching system and specialized parts it can also be used to make umbrella bags, sandwich bags and many different types of packaging.

Other Auxiliary Equipment

Categories : Control Equipment

Develop control system of other plastic machinery, such as extruder, bottle

Vertical Type Continuous Dryer

Categories : Dryers and Dehumidifiers For Plastic Materials

High efficiency dryer continues feeding wet materials and continues discharging materials improving traditional dryer to dry wet materials by lot saving your time and cost.

Polyamid 6 - NA1200GH50

Categories : PA(Polyamide) /Nylon

Glass fiber 50% reinforced, low warpage, high modulus, high impact. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

UZSII-800/1000W

Categories : Industrial Robots

Flame Laminating Machine

Categories : Extrusion Lamination Machines

The SA-6AF flame laminating machine is laminating equipment for laminating foam sheet with various type of fabrics by using gas burner. The burner installed over the whole working width and melts the surface of foam to be contact with the carrier material and produces like an adhesive on the surface for laminating. laminating foam sheet with various type of fabrics

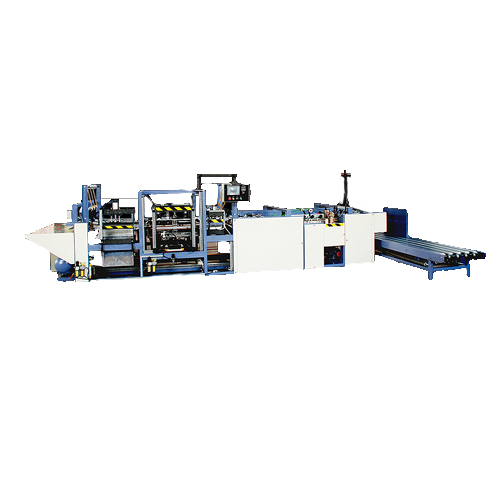

PP Woven Bag Related Machinery - JLVFM-SERIES

“ L ” cutting unit Valve forming unit Display screen operation interface

Motor with Gear Box

Categories : Motors

AC Small Motor with Gear Box -K Series】 This is a AC small motor combined with a gearbox. The motor is from 6W to 150W, and is used with the gearbox. The standard ratio of gearbox is from 1/3 to 1/180. If the gearbox ratio does not meet the requirements, you can replace the gearbox simply. The products are divided into single-phase motors equipped with capacitors or three-phase motors. The installation is simple and easy, so they are mostly installed in conveyor belt, packaging machine, food machinery, pharmaceutical machinery, automation machinery and other equipment. You can also choose AC small motors certified by UL or CE standards.

Secondary Packaging - Cartoning - CSC-50

Categories : Cartoning Machines

The cartoning equipment applies the vertical semi-automatic production operation. The equipment is suitable for more types with medium capacity products

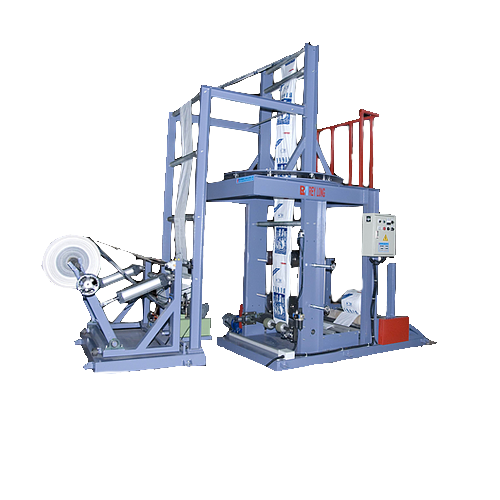

ABA Blown Film Machine (JC-ABA Series)

Categories : Co-Extrusion Blown Film Machines

JC-ABA Series - 3 layer Co-Extrusion Blown Film is the ultimate solution producing high quality film at lower production cost. The ABA 3 layer co-extrusion line consist two high performance extruders with a 3 layer ABA co-extrusion die head. The outer layer is dominantly with virgin materials, and the core layer with large percentage of CaCo3 or in-house recycled pellets material. Further the ABA 3 layer blown film structure also persist higher strength characteristic than conventional monolayer film, which overall gives an advantage to the competitive market.

Polyamid 66 - NB1200GH50

Categories : PA(Polyamide) /Nylon

Glass fiber 50% reinforced, low warpage, high modulus, high impact.

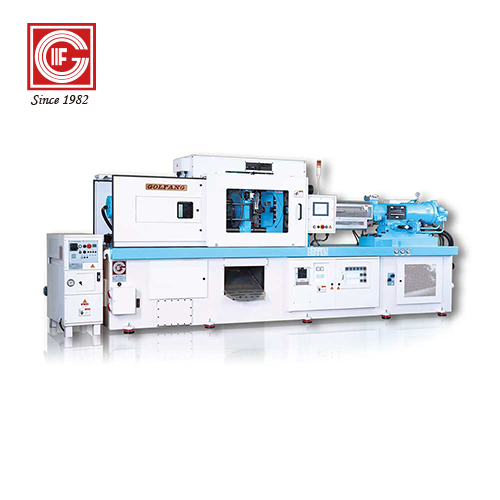

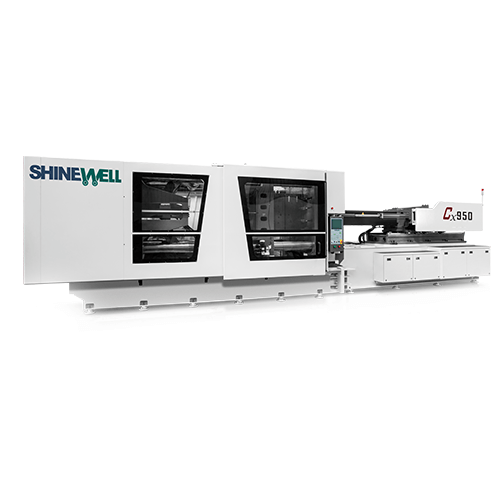

Servo Energy Saving Injection Molding Machine CX-60 – CX-1600

Categories : Horizontal Injection Molding Machines

APPLICATIONS:Packaging,Optics,Electronics,PET Preform,Closures,Cutlery,Thin Wall,Automotive

Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Horizontal Blow Molding Machines

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome. Co-extrusion application is the advanced technology by the leading brand: Full Shine.

P-20

Categories : Injection Molds

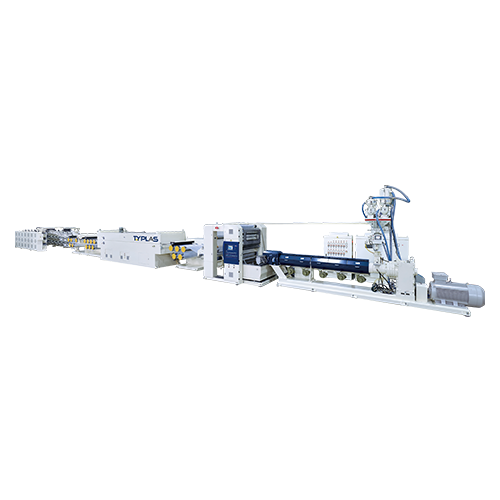

PP / HDPE Fibrillating Tape Line Making Machine-TLFB Series

Categories : Extrusion Lines For Filaments and Yarn

TLFB series is an economical design of extrusion tape line, and low power consumption produces high performance as the main feature

PP Woven Bag Related Machinery - JLRGSM-SERIES

Simple Operation Good accuracy Vertical type design

Flexo Plate Mounting Machine SM / PMM / EPM SERIES

Categories : Printing Machine Auxiliaries

KYMC has been producing the finest CI Flexo presses for over 20 years. As the market trends towards fast and shorter runs, we understand the importance of fast and accurate Flexo Plate Mounting Machine

Mixing Color Injection Molding Machine 120BS to 300BS

Categories : Injection Molding Machines by Color

Several embedded injection processes on two barrels to inject two melts on different stages. Times or positions to create different layouts are found in molding parts.

MULTI-LAYER AUTOMATIC FEED CUTTING MACHINE VAC-310

Categories : Foaming Machinery

Double-Axle Synchronous Pressurizing Mechanism: Performs the pressurization with double output axle to provide powerful and stabilized pressurizing capacity. Automatic Feed Mechanism: Uses servo control to carry out the setting according to the breadth and length of the material. Alignment Mold System: Performs concurrent cutting process after locking the material in place. Parameter Storing System: Performs module-based memory for the production figures to facilitate the parameter management. Cutting Plate Turntable Mechanism: Sets the offset length to achieve over 95% of plate utilization rate after cutting. High-Efficiency Boosting Circuit: Reduces over 30% of power consumption as compared to conventional circuit.

Pump

Categories : Pumps

FUNCTION Use air to drive hydraulic pump. Once the outlet hydraulic pressure reaches the setting pressure, it will stop driving and won't waste any energy. If the outlet pressure is reducing, it will supplement pressure automatically to maintain the pressure continuously. The outlet pressure of the pump and the pneumatic pressure of driving are as direct ratio. The outlet pressure will base on the adjustment of pneumatic pressure to change. The hydraulic pressure (available hydraulic pressure from 60 – 500 Kgf/㎝²) , flow rate of pump and circuit control system will base on the requirement to be different. The circuit control system has the function of check. If there is no pneumatic pressure, the hydraulic pressure will be maintained. The best application is for work clamping systems or hydraulic pressure supply system which needs to maintain pressure for a long time but less operate. It has the function of inspection pressure and can be interlocked with the machine.

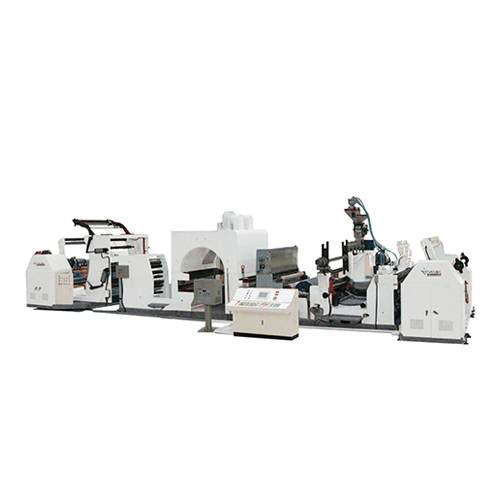

Extrusion Lamination Machine For Release Paper, Wrapper

● Unwinder and winder adopt duplex air shafts, auto alternant, splicing and roll change. ● Auto roll change and splicing with no speed reduction. ● Attach a corona treater as a standard equipment to ensure laminating quality. ● Attach a detector to enhance steady winding. ● Whole machine is synchronously controlled by PLC programmable, and easily operated through human machine interface.

Co-rotating Gearbox

Categories : Gearboxes