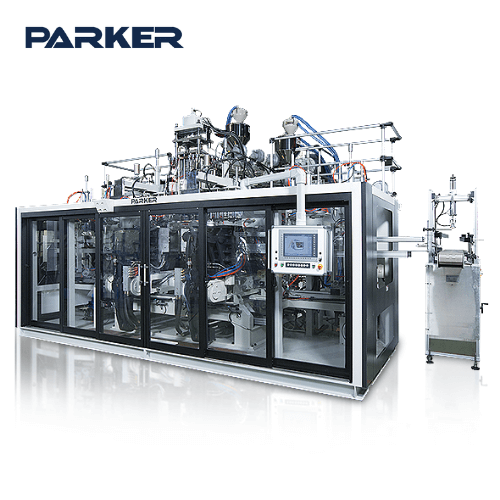

PET Stretch Blow Molding Machine - TEM06S2

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

PET Stretch Blow Molding Machine - TEM08S2

Categories : Automatic Blow Molding Machines

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. ● The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. ● Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. ● The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. ● Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. ● With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. ● Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. ● The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. ● Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

Semi-Automatic PET Stretch Blow Molding Machine - FS 1000HD

Categories : Automatic Blow Molding Machines

One Heating Machine Two Stretching Machine. -Small size and unoccupied space. It could produce 300c.c.~20Liter PET bottles and suitable for various bottles. -Semi-auto PET Stretch Blow Molding Machine is suitable for limited production but various products. -This type of machine can produce plastic containers for the widest range of product's capacity. Moreover, machine's size is small and occupies few space.

PET Stretch Blow Molding Machine - TEM08S2-88

Categories : Automatic Blow Molding Machines

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. ● The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. ● Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. ● The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. ● Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. ● With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. ● Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. ● The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. ● Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

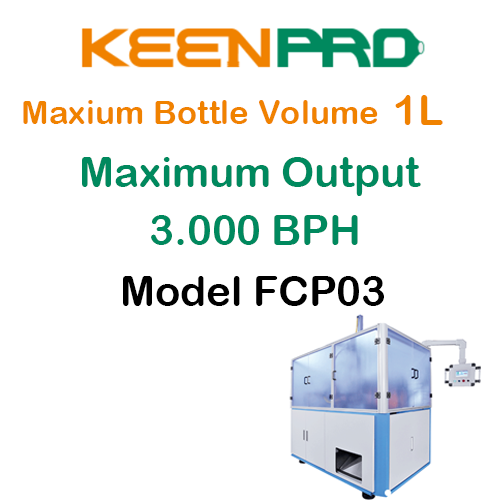

PET Blow Molding Machine - FCP03

Categories : Horizontal Blow Molding Machines

● Grouping Brand ● Parts Internationalization ● Apply for Small Production Line ● Complete Online Consultation Service ● QR code Intelligent Management ● Networkable Machine (Optional)

Medium Co-extrusion Blow Molding Machine

Categories : Electric Blow Molding Machines

Chen Way machinery is well-known for its 20L three layers blow molding machine. The recycle resins and the calcium carbonate (CaCO3) in the middle layer help to save material cost. Three layers M/C is the most popular choice for the edible oil export countries, production ranges from 5L to 30L jerry can. The outer and inner layer composed of 15%-20% virgin material and master batches. The middle layer can put around 60%-70% cost effective regrind material and also can add CaCo3 (no more than 30%), which can reduce cost down to 10-12% material cost. By contrast, the single layer jerry can only add around 5%-7% CaCo3 which has no evident improvement over material savings. Chen Way CWM

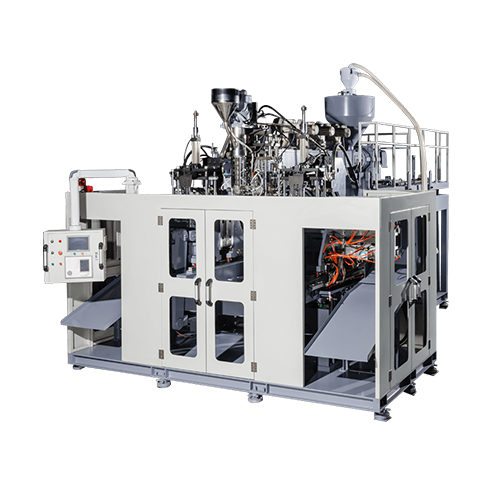

Medium Blow Molding Machine - Double Station

Categories : Electric Blow Molding Machines

Medium-Continuous Type Blow Molding Machine An all-rounder that is ideal for a variety of applications. Medium blow molding machines are used to produce medium-sized products but can also be adapted for small or large-scale productions. Products that are commonly manufactured by medium continuous blow molding machines include: 20/25L jerry cans 10/20L inner thread jerry cans Diamond-shaped jerry cans Round jerry cans Water tanks With applications for edible oil, lubrication oil, electronic, agriculture, and chemical liquids, this jerry can making machine is also available as a single or double station machine, for multi-layers, multi-cavities, or even multi-color productions.

Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Horizontal Blow Molding Machines

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome. Co-extrusion application is the advanced technology by the leading brand: Full Shine.