Precision Four-Column Plan Hydraulic Cutting Machine-CSS-202B

Categories : Foaming Machinery

●The body of the machine is made of special steel and has gone through rigorous processing that shows a ram pressure-resistant function and precision. ●Up and down stroke applies steel pole as the rail that brings out an effect of high precision and shaking-resistant characteristic. ●A design of Two-pod oil cylinder shows the stable force and large torsion.

High-accuracy Multi-Function Hydraulic Cutting Machine - CSS-603M

Categories : Cutting Machines

The machine body has been machined for several finishing processes in creating low-profile variable high-rigid machine body.

PRECISION HYDRAULIC AUTOMATIC DIE-CUTTING MACHINE/4COLUMU TYPE CSS-603

Categories : Cutting Machines

Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance. 4 steel posts design instead of guide-ways for punching movement and equipping linear guide-way for the front & rear feeders. The unit performs precisely, stably, quietly, nimble and powerful. lt'sconvenient even for the use at the upstairs of a factory. Cutting depth can be precisely set up to a tolerance of 0.008 mm. Through the use of the longwearing special designed steel plate to replace conventional cutting board, can prolong lift of cutter and obtain better cutting quality and efficiency Processed item may be full or half cut-off. ltems with adhesive may be used as well Products are free from rough edges. The machine is equipped with a protecting device to ensure safety of people and the machine. Automatic cooling system and full-auto cutting device are available for additionally purchase and fitting. Designed in high-precision construction, this machine can be used to perform full-cut and half-cut fabrication tasks. Up/down punching travel uses four high-rigidity guide poles, with linear rail designed for the feeding mechanism. Two-step pressure control to achieve flexible and lower noise operation. It is suitable for multi-level factory buildings. Automatic cutter adjusting mechanism can perform automatic adjustment according to the desired setting, providing 0.01mm accuracy (0.001mm optional). High-precision german steel plate is used to achieve higher durability and wear free operation. This machine uses advanced and durable hydraulic system and electronic control circuits. The machine is equipped with protection device to ensure the safety of the operator and the machine. (with CE optional)

High Speed Precision Vertical Injection Molding Machine-YQ Series

Categories : Vertical Injection Molding Machines

• Vertical four-pillar vertical clamping, with vertical injection. • The square pillar design comes with large mold size. The space within the column allows customers to install devices of automatic embedding and removing products. This allows automation for the whole machinery. • Big L / D ratio of screw, plasticizing evenly, suitable for injection molding of engineering plastics. • High standard computer control system with high precision injection pressure and high response injection speed. The quality is more stable for high-precision embedded injection molding products. • 1S single sliding: After mold opening, the lower mold will automatically slip in front of the operator for facilitating embedded molding operation. • 2S double sliding (Alternating double sliding): One mold for injection molding, another mold for taking out and putting on embedded parts operation. • 2SL double sliding (90°Alternating double sliding): One operator can operate independently. One mold for injection molding, another mold for material taking and putting on embedded parts. The two slidings are intersecting at 90 degrees, which can lower the production cost, and enhance the performance. • Able to combine automation and the high-speed injection can effectively enhance the production capacity. • A variety of circuit design (half closed servo hydraulic or high speed injection) to meet the customer’s requirements.

High Speed Injection Molding Machine (TSV Series)

Categories : Hydraulic Clamping Injection Molding Machines

• The double hydraulic cylinder provides secure hold on pressurefor the injection carriage eliminating nozzle leakage. • The toggles are lubricated with the graphite bronze bushes to ensure lower friction wear, assure greater accuracy and greatlyextended life of the clamp unit. • Fast clamping system equipped with regeneration circuit increase speed by 60% to shorten cycle time and save energy. • Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportion-al valves is more precise resulting in more accurate control.

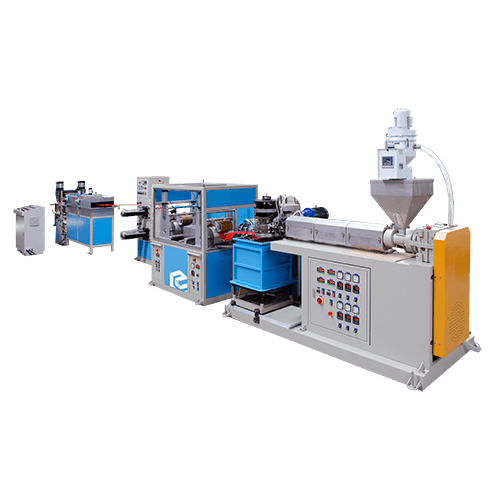

Net Extrusion Machine Line

The Everplast mesh production line is designed for high production demands. Provides high productivity, high precision, and excellent mesh surfaces. The screw is precision machined from high-quality alloy steel SACM-1 and nitrided to provide high performance and durability, ensuring high extrusion capacity and automatic temperature control. The entire machine's movement is controlled by a high-efficiency controller, making it easy to operate.

High Precision CCD Auto Positioning Die-Cutting Machine-APL-500CCD

Categories : Foaming Machinery

●Designed in high-precisio construction, this machine can be used to perform full-cut & half-cut fabrication tasks. ●Up/down punching travel uses four high-rigidity guide poles, with liner rail designed for the feeding mechanism. ●Automatic cutter adjusting mechanism can perform automatic adjustment according to the desired setting, providing 0.01mm accuracy. ●High speed mult-axis servo control system, increases efficiency. ●High quality CCD positioning system, fast operation and high accuracy. ●Powerful, high rigidity cam drive system for high stability. ●The machine is equipped with protection device to ensure the safety of the operator and the machine. (with CE optional)

CE Safety Conformity Type - Single Station

Categories : Compression Molding Machines

Compression Molding Machine ●High steel 4-Column style mechanism with high precision of parallelism. Adjustable daylight accommodates different height of molds. ●Designed by Finite Element Analysis (F.E.A.) ensures high safety factor and durability. ●Vacuum cover design reduces curing time, increases vacuum efficiency. ●Diversified Stripping Device suitable for various types of molds opening. ●Safety Interlock prevents operation errors.

HIGH ACCURACY POLARIZER CUTTER TRC-1200

Categories : Cutting Machines

Stable Bottomdead Center Accuracy: The delicate-design mechanism can maintain the stable bottomdead center accuracy under high speed cutting running. Knife Height Adjustment Mechanism: When setting up knife mold, the instrument of the machine can make right and left adjustment respectively as well as complete the setup of knife mold clearly and rapidly. Easy-Operate Operation Panel: This machine adopts new touch screen featuring affinity operation interface that makes an easy operation, thus lowering cost for employee training. Accuracy Delivery Mechanism: Oaded with new mechanism, the delivery move volume digital setup, it achieves a stable an accurate delivery function. High Speed Cutting: The strengthened-design mechanism can allow high speed cutting. High Torsiodamper: With the strong rigidity of the unit, noise can be maintained within the standard value under high speed running.

High-accuracy Mini-sized Automatic Cutting Machine-APL-300

Categories : Foaming Machinery

●Well-designed and Stabilized Bottom Dead-point Accuracy: Specially designed machine structure and basic machining method, which provides extremely high cutting accuracy and stability. ●User Friendly Operation Interface: Digitalized parameter setting to facilitate the SOP management, while saving lengthy education and training time. ●Automatic Lubrication System: With Automatic Lubrication System, it simplifies the procedure of daily maintenance. ●Cutting Depth Adjusting Mechanism: Totally digitalized depth adjustment in achieving convenient and fast adjusting. ●Full-cut and Semi-cut Machining Effect: The cutting depth can be adjusted to the minimal 0.003mm in providing high accuracy for easier full-cut and semi-cut machining effect. ●Secondary Machining Flexibility: It is flexible for carrying out inter-station alignment cutting. ●Steel Form Cutting Flexibility: It supports steel form punching and cutting.

Inverter / Inverter Duty Motor-VFEF Series

Categories : Motors

Higher precision motion control and speed adjustment to make the machine in automation, high production capacity purpose.

High-accuracy Compact Auto-Cutting Production Line-APL-300

Categories : Foaming Machinery

●Servo Cutting Mechanism: The Main Cutting Axle is controlled by Servomotor to achieve high-efficiency and high-accuracy effects. ●Auto Feed Mechanism: It is controlled by High-level Servo to achieve faster feeding speed and more accurate alignment. ●On-line with Multi-axle Auto Bonding Machine: It is communicating with RAL-400 High-accuracy Auto Bonding Machine for carrying out synchronized operation. ●On-line with Auto Slicer: It is communicated with AC-300 Compact Slicer for carrying out slicing operation. ●Secondary Processing Correspondence: It corresponds with the alignment cutting operation between two stations.