Five and Seven-Layer Co-Extrusion High Speed Blown Film Line

Categories : Co-Extrusion Blown Film Machines

K.S. became a worldwide company; have achieved ISO 9002 certificate's requirements. K.S. machinery conforms to CE standard. Moreover, every machine must pass K.S. strict and careful quality control system, and pass test running before shipping out to the customer.

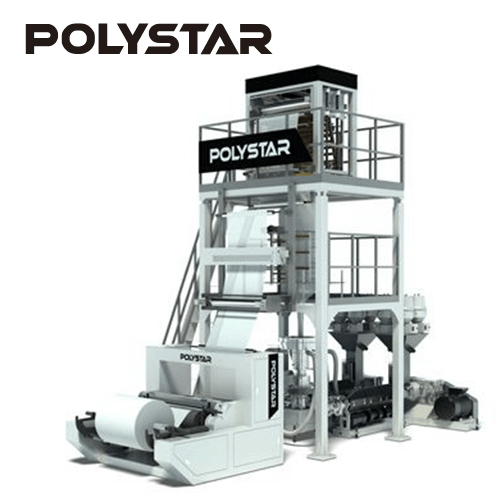

ABA Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

● ABA 3 Layer Co-extrusion ● Film Width from 500~1500mm ● Extruder Dia: 40mm,45mm, 55mm, 65mm ● Material: HDPE,LDPE, LLDPE,CaCO3, Additives ● Output: 45~150 kgs/hr

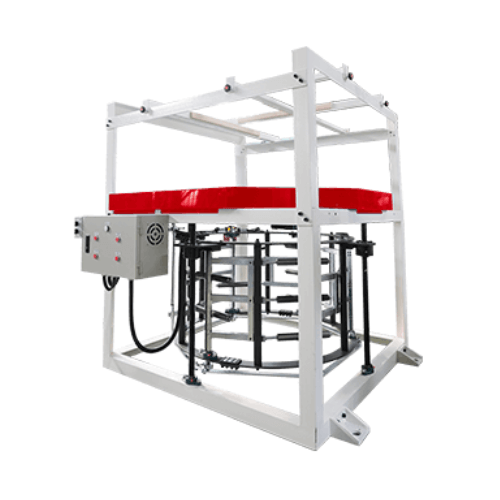

Bubble Cage by Motor Control

Categories : Blown Film Extruder Parts

Blown Film Extrusion Machine is a process that extrudes the molten polymer through Blown Film Die Head to process the plastic film. If the bubble tube is unstable when it first comes out from the Die Head, it needs a support to maintain its stability to prevent it from transforming. Therefore, Bubble Cage by Motor Control play important characters here to stabilize and reinforce the blown film bubble tube while blowing. As the cooling system runs well around the circumference of the bubble tube, the Bubble Cage by Motor Control maintains the stability of the bubble tube over Die Head and Air Ring. It prevents the bubble tube from losing stability and offers higher quality of film which shows the importance of Bubble Cage by Motor Control. HSIN LONG

Blown Film Bubble Cage/Basket

Categories : Blown Film Extruder Parts

Blown Film Extrusion Machine is a process that extrudes the molten polymer through Blown Film Die Head to process the plastic film. If the bubble tube is unstable when it first comes out from the Die Head, it needs a support to maintain its stability to prevent it from transforming. Therefore, Blown Film Bubble Cage / Basket play important characters here to stabilize and reinforce the blown film bubble tube while blowing. As the cooling system runs well around the circumference of the bubble tube, the Bubble Cage / Basket maintains the stability of the bubble tube over Die Head and Air Ring. It prevents the bubble tube from losing stability and offers higher quality of film which shows the importance of Bubble Cage / Basket. HSIN LONG

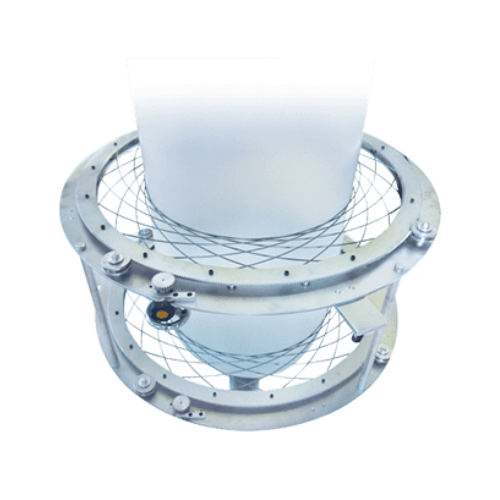

Stabilizer

Categories : Blown Film Extruder Parts

The wires of stabilizing ring with SUS304 for increased. Easy to adjust. Single or double layer assemble easily. Mass production, competitive prices. Choice of various ring diameters. Blown Film Extrusion Machine is a process that extrudes the molten polymer through Blown Film Die Head to process the plastic film. If the bubble tube is unstable when it first comes out from the Die Head, it needs a support to maintain its stability to prevent it from transforming. Therefore, Stabilizer play important characters here to stabilize and reinforce the blown film bubble tube while blowing. As the cooling system runs well around the circumference of the bubble tube, the Stabilizer maintains the stability of the bubble tube over Die Head and Air Ring. It prevents the bubble tube from losing stability and offers higher quality of film which shows the importance of Stabilizer. HSIN LONG

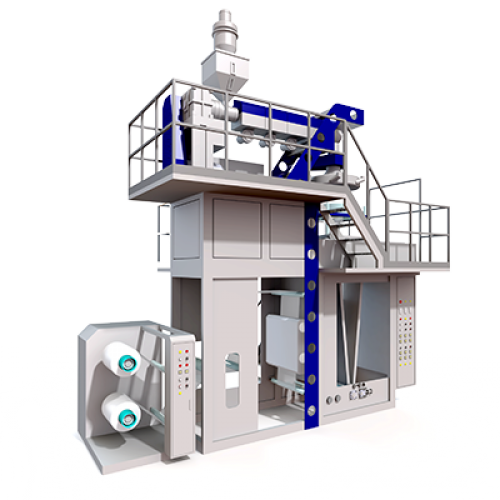

ABA Three-layer Co-extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

Mini HDPE/LDPE Blown Film Line (JC-HM Series)

Categories : Blown Film Extruders

JC-HM Series Mini HDPE/LDPE Blown Film Extrusion Line is the most cost-effective solution for high speed monolayer film production. Emphasize for high speed monolayer film production. Emphasize on reliability, easy operation, flexibility and swift product change.

PP Blown Film Line(JC-PB Series)

Categories : Blown Film Extruders

JC-PB Series Blown Film Extrusion Line is downward inflation water cooling line for production of high clarity PP film.

ABA Blown Film Machine (JC-ABA Series)

Categories : Co-Extrusion Blown Film Machines

JC-ABA Series - 3 layer Co-Extrusion Blown Film is the ultimate solution producing high quality film at lower production cost. The ABA 3 layer co-extrusion line consist two high performance extruders with a 3 layer ABA co-extrusion die head. The outer layer is dominantly with virgin materials, and the core layer with large percentage of CaCo3 or in-house recycled pellets material. Further the ABA 3 layer blown film structure also persist higher strength characteristic than conventional monolayer film, which overall gives an advantage to the competitive market.